A method for simultaneous extraction of taurine and polysaccharides from abalone viscera

A technology of abalone viscera and taurine, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of cumbersome process, large pollution, large energy consumption, etc., and achieves overcoming the cumbersome process and reducing production. cost, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

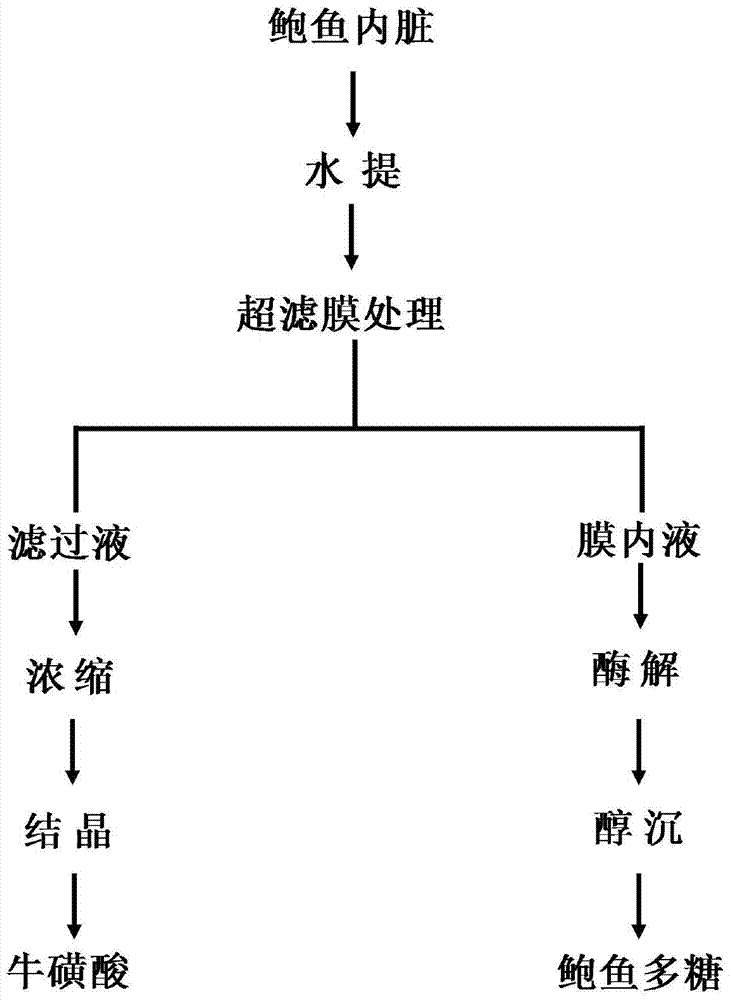

Image

Examples

Embodiment 1

[0035] Embodiment 1: Extraction of natural taurine and abalone polysaccharide in abalone viscera

[0036] (1) Source of raw materials: 2 kg of cleaned abalone viscera;

[0037] (2) Water extraction: add 6 L of water, mash the tissue, heat in a water bath at 80°C for 3 h, and filter with gauze to obtain 7.50 L of filtrate;

[0038] (3) Ultra-fol ultrafiltration membrane treatment: 7.50 L of the collected filtrate was pumped into the Ultra-fol ultrafiltration membrane equipment for membrane separation treatment, and 700 mL of water was added for top washing to obtain 7.60 L of filtrate, which was obtained in the membrane Liquid 500 mL;

[0039] (4) Enzymolysis: Add 0.5% by weight of neutral protease to the obtained 500 mL of membrane inner solution, and enzymolyze at 55°C for 2.5 hours;

[0040] (5) Alcohol precipitation: collect the enzymatic solution, add 2 times the volume ratio of 95% ethanol solution, let it stand for precipitation at room temperature for 12 hours, centrifu...

Embodiment 2

[0043] Embodiment 2: Extraction of taurine and abalone polysaccharide in abalone viscera

[0044] (1) Source of raw materials: 5 kg of cleaned abalone viscera;

[0045] (2) Water extraction: Add 20 L of water, mash the tissue, heat in a water bath at 90°C for 2 h, and filter with gauze to obtain 19.47 L of filtrate;

[0046] (3) Ultra-fol ultrafiltration membrane treatment: 19.47 L of the collected filtrate was pumped into the Ultra-fol ultrafiltration membrane equipment for membrane separation treatment, and 1 L of water was added for top washing to obtain 19 L of filtrate, which was obtained in the membrane Liquid 1.25 L;

[0047] (4) Enzymatic hydrolysis: Add 0.5% by weight of neutral protease to the obtained 1.25 L membrane inner solution, and enzymatically hydrolyze at 55°C for 2.5 hours;

[0048] (5) Alcohol precipitation: collect the enzymatic solution, add 4 times the volume ratio of 95% ethanol solution, let it stand for precipitation at room temperature for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com