Uniform compaction method of silicon oxide based antenna housing composite

A composite material and radome technology, applied in the field of composite materials, can solve the problems of differences in temperature field distribution of heat treatment furnaces, long preparation period of radome materials, etc., and achieve the effects of improving drying efficiency, avoiding overflow and loss, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

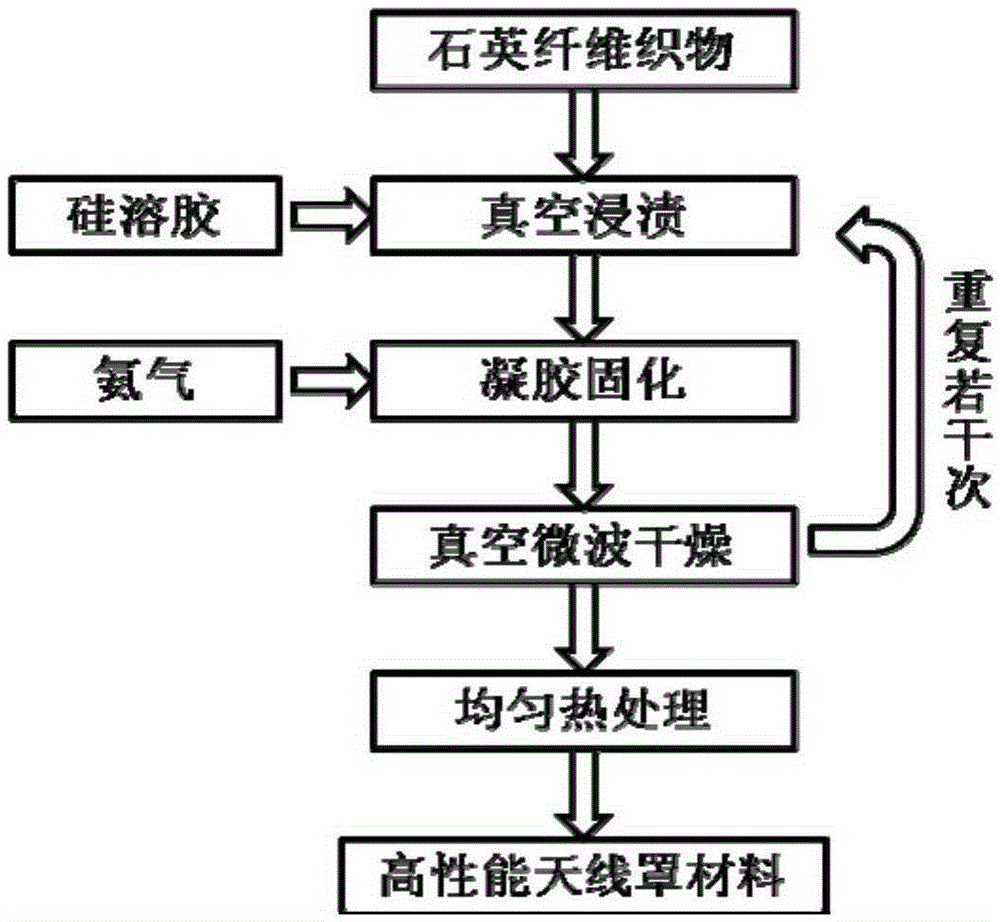

[0040] like figure 1 Shown is the flow chart of the preparation method of the composite material of the present invention, and the uniform densification method of the silicon oxide-based radome composite material of the present invention specifically includes the following steps:

[0041] (1) Put the fiber fabric into the impregnation tank, pour silica sol, seal the impregnation tank and evacuate, the vacuum degree of vacuuming is -0.06~-0.1MPa, and keep for 60~120min after reaching the target vacuum degree. Wherein the silica sol is an acidic silica sol with a pH value between 2-3.

[0042] The inner cavity of the dipping tank is designed according to the shape of the fabric to save the amount of silica sol. The minimum amount of silica sol added should be greater than the weight of the fabric and ensure that the fabric is completely immersed in it during the entire impregnation process.

[0043] (2) Stop vacuuming, and feed ammonia gas. When the pH value of the silica sol r...

Embodiment 1

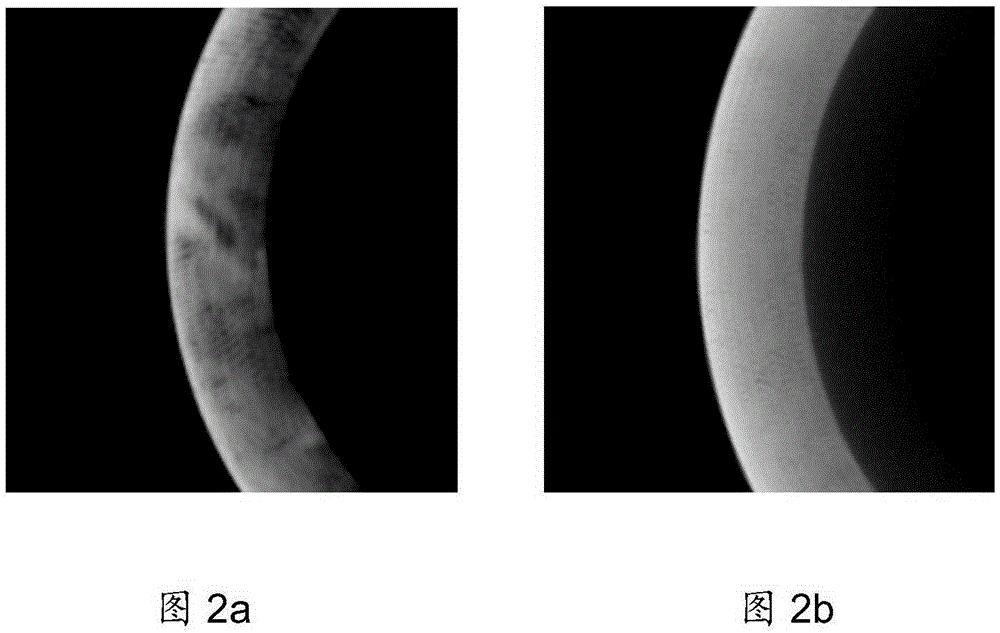

[0056] put the size as A conical fabric (made of quartz fiber) is put into a conical dipping tank with a conical cavity, and the pH=2.6 silica sol is poured in to ensure that the fabric is completely immersed in the silica sol; the dipping tank is sealed and vacuumed to -0.09 MPa, keep the vacuum for 90min; stop vacuuming, feed ammonia gas until the pH value of the silica sol reaches 5.5, let it stand for 60min, heat the dipping tank to 70°C, and keep it warm for 120min to make the silica sol gel; take out the fabric from the dipping tank, and Clean up the wet gel on the surface of the fabric, vacuum microwave the fabric, place the fabric in the center of the microwave drying device covered with a quartz plate, and then start vacuuming to -0.07MPa, then heat while rotating, and the heating temperature is 150 ℃, the heating time is 60min; repeat the above process 10 times, then put the fabric on the rotating platform covered with quartz felt in the heat treatment furnace for h...

Embodiment 2

[0059] Put the flat fabric (woven by quartz fiber) with a size of 300×300×30mm into a dipping tank whose inner cavity is a square, pour silica sol with pH=3 to ensure that the fabric is completely immersed in the silica sol; seal the dipping tank and Vacuum to -0.06MPa, keep the vacuum for 60min; stop vacuuming, feed ammonia gas until the pH value of the silica sol reaches 7.5, let it stand for 30min, heat the dipping tank to 80°C, and keep it warm for 60min to make the silica sol gel; from the dipping tank Take out the fabric, clean the wet gel on the surface of the fabric, vacuum microwave the fabric, place the fabric in the center of the microwave drying device covered with quartz cloth, and then start vacuuming to -0.05MPa, and heat while rotating , the heating temperature is 100°C, and the heating time is 20min; repeat the above process 20 times, and then put the fabric on a rotating platform covered with a quartz plate in a heat treatment furnace for heat treatment, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com