Environment-friendly multifunctional brick and preparation method thereof

An environmentally friendly, brick-concrete technology, applied in the field of building materials, can solve the problems of urban environmental pollution, waste, natural resource destruction, etc., and achieve the effects of being less prone to damage and cracking, reducing consumption, and preventing water absorption and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

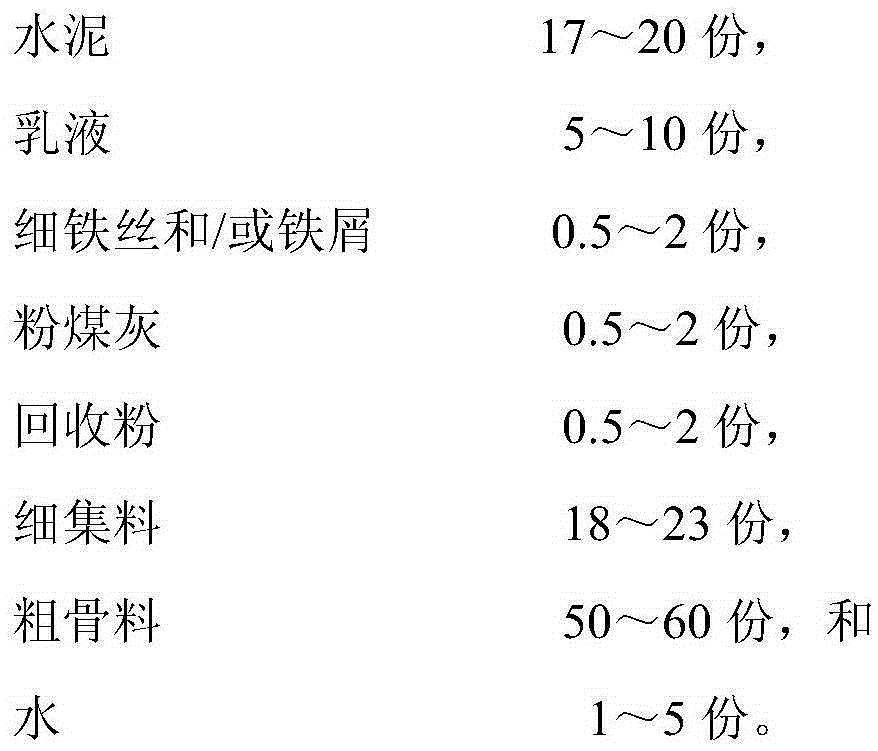

[0032] An environmentally friendly multi-purpose brick of the present invention is prepared from the components of Group A shown in Table 1 in parts by mass. Group B in Table 1 is a comparative example.

[0033] Each raw material component and mass parts in table 1 embodiment 1 and comparative example

[0034] Component

Group A (number of copies)

Group B (number of copies)

20

20

5

0

fine wire and filings

1

1

0.5

0.5

recycled powder

1.5

1.5

fine aggregate

20

20

Coarse aggregate

50

50

water

2

7

[0035] In this embodiment, the cement is Portland cement, and the strength grade of Portland cement is 32.5; the emulsion is water-based acrylic emulsion, and the solid content of the water-based acrylic emulsion is 30%; the thin iron wire and iron filings are all waste and old products produced by the factory. Fine ir...

Embodiment 2

[0044] An environmentally friendly multi-purpose brick of the present invention is prepared according to the raw materials and mass parts shown in Table 2, and the specific selection of raw materials is the same as that in Example 1.

[0045] Each raw material component and mass parts in table 2 embodiment 2

[0046] Component

parts by mass

cement

20

5

fine wire and filings

1

1

recycled powder

1

[0047] fine aggregate

20

Coarse aggregate

50

water

2

[0048] A preparation method of the environmental protection multi-purpose brick of the above-mentioned present embodiment, comprising the following steps:

[0049] (1) According to Table 2, mix fine aggregate, coarse aggregate, fly ash, and recycled powder evenly, then add cement, emulsion, fine iron wire, and iron filings, and after mixing evenly, add water and stir evenly to obtain a mixture ...

Embodiment 3

[0054] A kind of environment-friendly multi-purpose brick of the present invention is prepared according to the raw materials and mass parts shown in Table 3, and the specific selection of raw materials is the same as that of Example 1.

[0055] Each raw material component and mass parts in table 3 embodiment 3

[0056] Component

parts by mass

cement

19

5

fine wire and filings

1

fly ash

2

recycled powder

1

fine aggregate

20

Coarse aggregate

50

water

2

[0057] A preparation method of the environmental protection multi-purpose brick of the above-mentioned present embodiment, comprising the following steps:

[0058] (1) According to Table 3, mix fine aggregate, coarse aggregate, fly ash, and recycled powder evenly, then add cement, emulsion, fine iron wire, and iron filings, after mixing evenly, add an appropriate amount of water, and stir evenly to obtain Mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com