A kind of alkali-free liquid accelerator based on synthetic polyaluminum sulfate

A technology of polymerizing aluminum sulfate and aluminum sulfate, applied in the field of concrete admixtures, can solve the problems of corroded skin, reduced strength of shotcrete, and high alkali content of accelerators, and achieves the effect of less skin erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method based on synthetic polyaluminum sulfate novel alkali-free liquid quick-setting agent, characterized in that: the preparation method based on synthetic polyaluminum sulfate novel alkali-free liquid quick-setting agent comprises the following steps:

[0042] A. Dissolve aluminum sulfate in water, heat to 60-80°C, and adjust to Al 2 (SO 4 ) 3 The solution concentration is 140-150g / L;

[0043] B. Prepare a solution of ammonia water and water at a ratio of 1:3, gradually add it to the aluminum sulfate solution, control the temperature at about 35-45°C and keep the stirring speed not lower than 150 rpm, and adjust the pH to 6.2-6.7 for titration End point, obtain active aluminum hydroxide gel;

[0044] C. Put the activated aluminum hydroxide in the container and let it stand for 1-2 hours, suck out the supernatant liquid by siphon, and continue to add water to dilute and wash, repeat this way 4-5 times to obtain activated aluminum hydroxide gel with go...

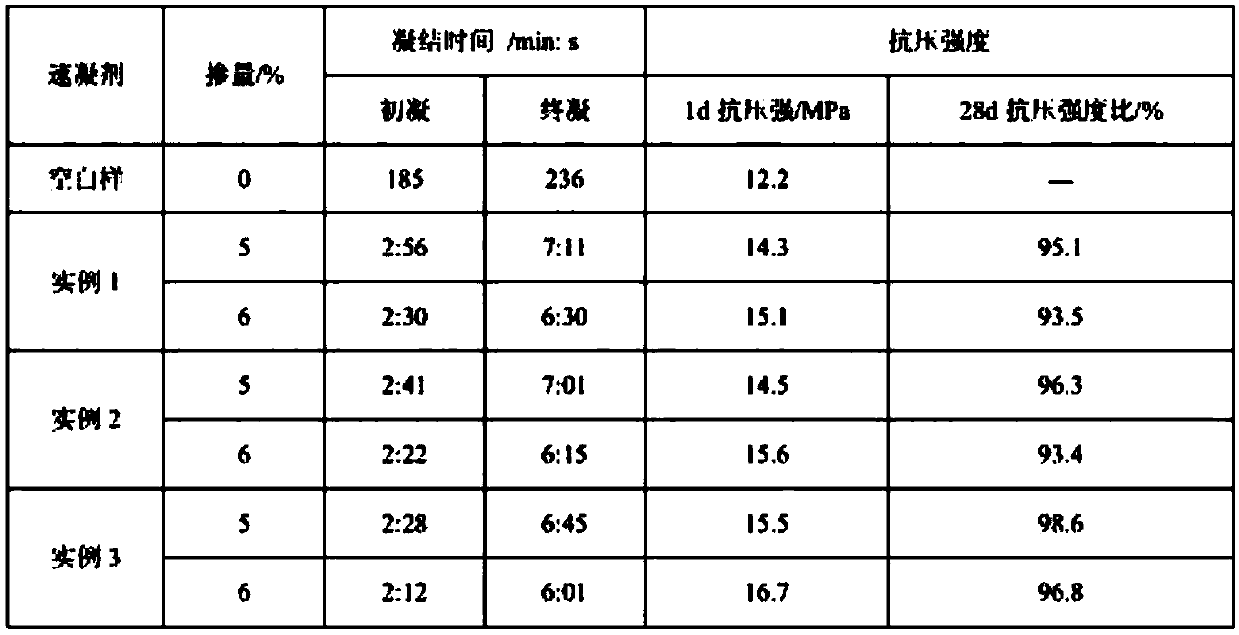

Embodiment 1

[0053] Take 90 parts of industrial-grade aluminum sulfate and add 240 parts of water, heat the water bath to 80°C and keep the stirring speed not lower than 150 rpm. After all the aluminum sulfate is dissolved in water, reduce the temperature to 35-45°C;

[0054] Make a solution of ammonia water and water at a ratio of 1:3, gradually add the ammonia solution to the aluminum sulfate solution, control the temperature at about 35-45°C and keep the stirring speed not lower than 150 rpm, and adjust the pH to 6.2-6.7 as Titrate the endpoint to obtain active aluminum hydroxide gel suspension;

[0055] Put the activated aluminum hydroxide in the container and let it stand for 1-2 hours, suck out the supernatant by siphon, and continue to add water to dilute and wash, repeat this way 4-5 times to obtain activated aluminum hydroxide gel with good performance. Filter the gel to obtain a filter cake, dry the filter cake at 80°C for 8 to 10 hours, and pass through a 80 μm sieve to obtain w...

Embodiment 2

[0058] Take 100 parts of industrial-grade aluminum sulfate and add 250 parts of water, heat the water bath to 80°C and keep the stirring speed not lower than 150 rpm. After all the aluminum sulfate is dissolved in water, reduce the temperature to 35-45°C;

[0059] Make a solution of ammonia water and water at a ratio of 1:3, gradually add the ammonia solution to the aluminum sulfate solution, control the temperature at about 35-45°C and keep the stirring speed not lower than 150 rpm, and adjust the pH to 6.2-6.7 as Titrate the endpoint to obtain active aluminum hydroxide gel suspension;

[0060] Put the activated aluminum hydroxide in the container and let it stand for 1-2 hours, suck out the supernatant by siphon, and continue to add water to dilute and wash, repeat this way 4-5 times to obtain activated aluminum hydroxide gel with good performance. Filter the gel to obtain a filter cake, dry the filter cake at 80°C for 8 to 10 hours, and pass through a 80 μm sieve to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com