Asphalt waste material recycling process

An asphalt waste and process technology, applied in the field of waste recycling and regeneration process, can solve problems such as properties inferior to asphalt concrete, no open recycling technology, and inability to eliminate waste utilization, so as to reduce engineering costs, be conducive to environmental protection, reduce maintenance and The effect of pollution costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

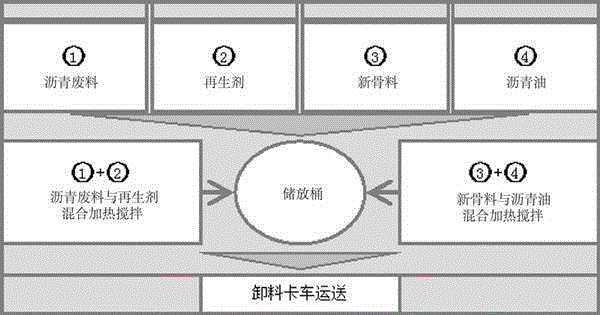

[0021] A kind of bituminous waste reclaiming regeneration process, described regeneration process mainly comprises the following steps:

[0022] Step 1: Prepare production equipment and testing instruments; the production equipment mainly includes a storage barrel with stirring function, two stirring pots, two oil delivery pipes, weighing equipment and fuel injection equipment; the testing equipment mainly includes Extractor and viscosity tester;

[0023] Step 2: Prepare recycled materials; the recycled materials include removing recycled asphalt waste, regeneration agent, asphalt oil and new aggregates used in asphalt production, crushing asphalt waste, and dividing them into coarse and fine materials according to particle size. material;

[0024] Step 3: Measure recycled materials; weigh asphalt waste with scale equipment, measure the oil content of asphalt waste with an extractor, and test the viscosity of asphalt waste with an annual tester, and then according to the oil ...

Embodiment 1

[0035] Embodiment 1: The asphalt road surface layer of 250 square national roads is recycled.

[0036] Using the recycling technology of the present invention, the paving test of waste recycled asphalt concrete was carried out on July 12, 2014. The test time was 9:30 am to 11:30 am, the outdoor temperature was 31°C, and the test area was 250 square meters, which was used for national highways. asphalt road surface.

[0037] Step 1: Prepare production equipment and testing instruments; the production equipment mainly includes a storage barrel with stirring function, two stirring pots, two oil delivery pipes, weighing equipment and fuel injection equipment; the testing equipment mainly includes Extractor and viscosity tester;

[0038] Step 2: prepare regenerated materials; described regenerated materials include removing recycled asphalt waste, regeneration agent, asphalt oil and new aggregate used in producing asphalt, and crushing 250 square meters of asphalt waste that has b...

Embodiment 2

[0041] Embodiment 2: Recycle and regenerate the asphalt pavement of 500 square meters of national roads.

[0042] The paving test of waste recycled asphalt concrete was carried out on August 5, 2014 by using the recycling technology of the present invention. The test time was 8:30 am to 12:20 am, the outdoor temperature was 29-32°C, and the test area was 500 square meters. Asphalt pavement on national highways.

[0043] Step 1: Prepare production equipment and testing instruments; the production equipment mainly includes a storage barrel with stirring function, two stirring pots, two oil delivery pipes, weighing equipment and fuel injection equipment; the testing equipment mainly includes Extractor and viscosity tester;

[0044] Step 2: Prepare recycled materials; said recycled materials include removing recycled asphalt waste, regeneration agent, asphalt oil and new aggregate used in producing asphalt, and crushing 500 square meters of asphalt waste that has been planed out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com