Cutting device applied to production and processing of tubular glass

A cutting device, glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of tubular glass breakage, increased cost, waste of resources, etc., to improve stability, prolong service life, and improve the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

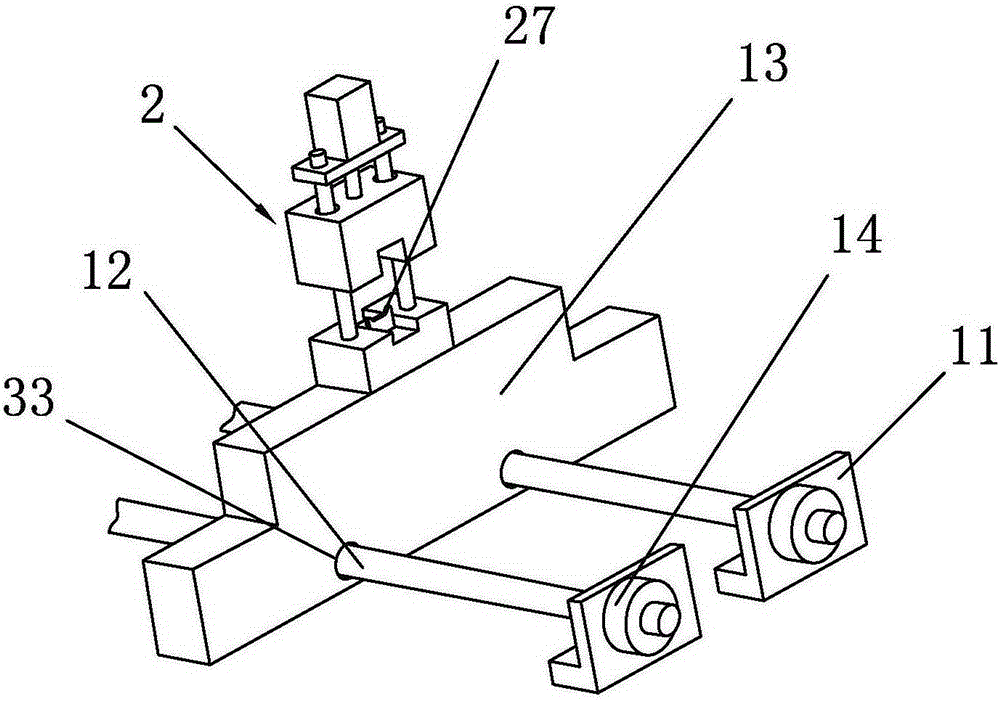

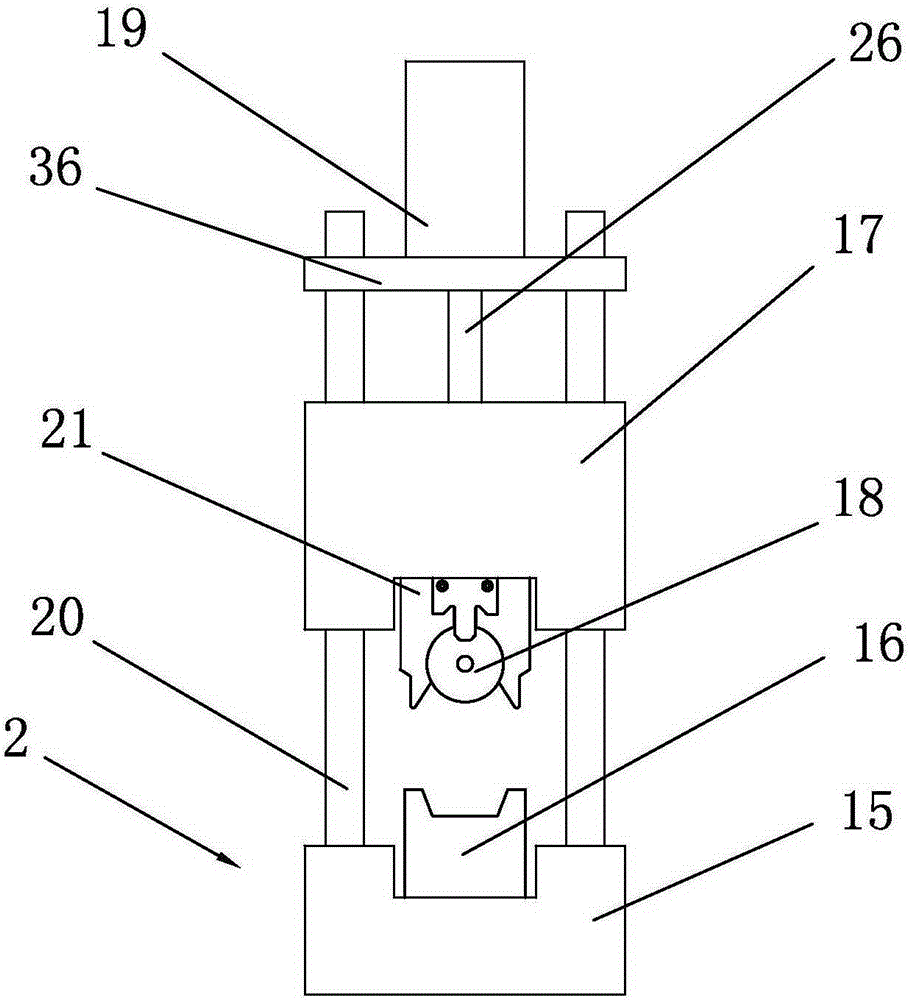

[0031] Such as Figure 1 to Figure 5 As shown, it is a cutting device applied to the production and processing of tubular glass according to the present invention, including a workbench, a clamping device 1, a sliding assembly and a cutting assembly 2, the workbench includes a first workbench 3 and a second workbench 4, and the first workbench A storage cabinet 31 and an operation console 32 are arranged on the front end of the workbench 3, and the operation console 32 is provided with a display screen and operation buttons. The design of the storage cabinet 31 can place maintenance tools and cleaning tools therein, making it easier to use Convenient, the operator can observe the cutting parameter value and cutting status of the tubular glass 37 through the display screen, the design of the operation button can make the use of the whole cutting device easier and improve the safety performance of the whole device. The bottom is provided with universal wheel 28 and support colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com