Low temperature boiling chlorination furnace and temperature-controllable low-temperature boiling chlorination process

A boiling chlorination furnace, boiling chlorination technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of waste of resources, chlorination rate, rapid drop of chlorination furnace temperature, dead furnace shutdown, etc., to reduce consumption , Improve the chlorination rate and reduce the discharge amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated and illustrated below in conjunction with the embodiments of the present invention.

[0028] The carbide slag used in the present invention is the blast furnace slag obtained by blast furnace smelting of ilmenite (such as vanadium-titanium magnetite) and then formed after carbonization. In one embodiment, the carbide slag contains 6-14wt% titanium carbide TiC . In addition, titanium tetrachloride TiCl 4 It is liquid at room temperature 25°C, and its boiling point is 136.2°C.

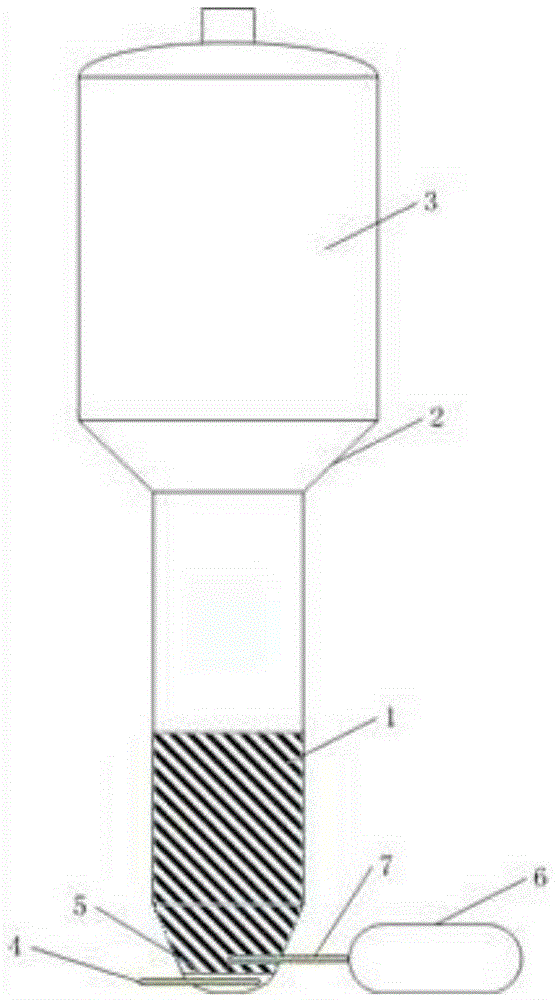

[0029] Such as figure 1 Shown, the low-temperature boiling chlorination furnace of the present invention comprises the reaction section 1 that is used to carry out boiling chlorination, expansion section 2, settling section 3, is used to provide the inlet pipe 4 of chlorine and fluidizing gas such as nitrogen to the bottom of reaction section And distribution plate 5 for distributing gas, and low-temperature boiling chlorination furnace also comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com