Low-temperature fluidizing chlorination method and low-temperature fluidizing chlorination furnace

A boiling chlorination furnace and boiling chlorination technology, applied in the direction of titanium halide, etc., can solve the problems of waste of chlorination rate, dead furnace shutdown, difficult control of reaction temperature, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

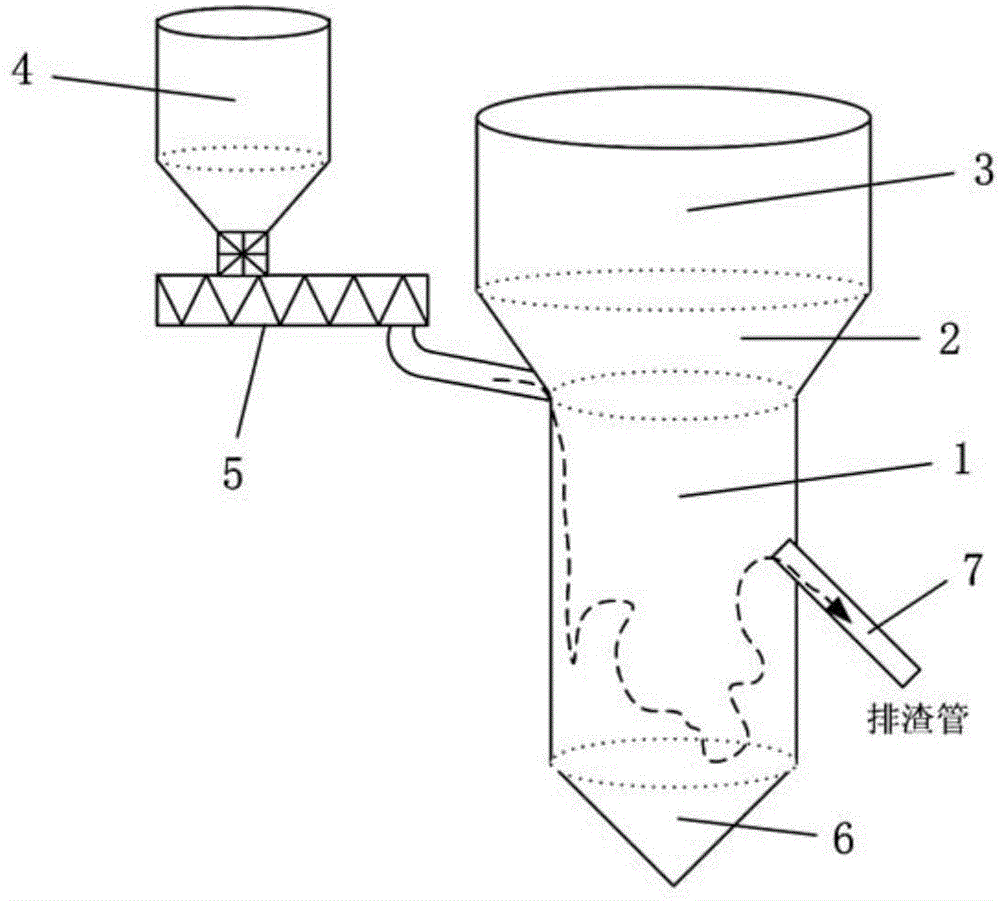

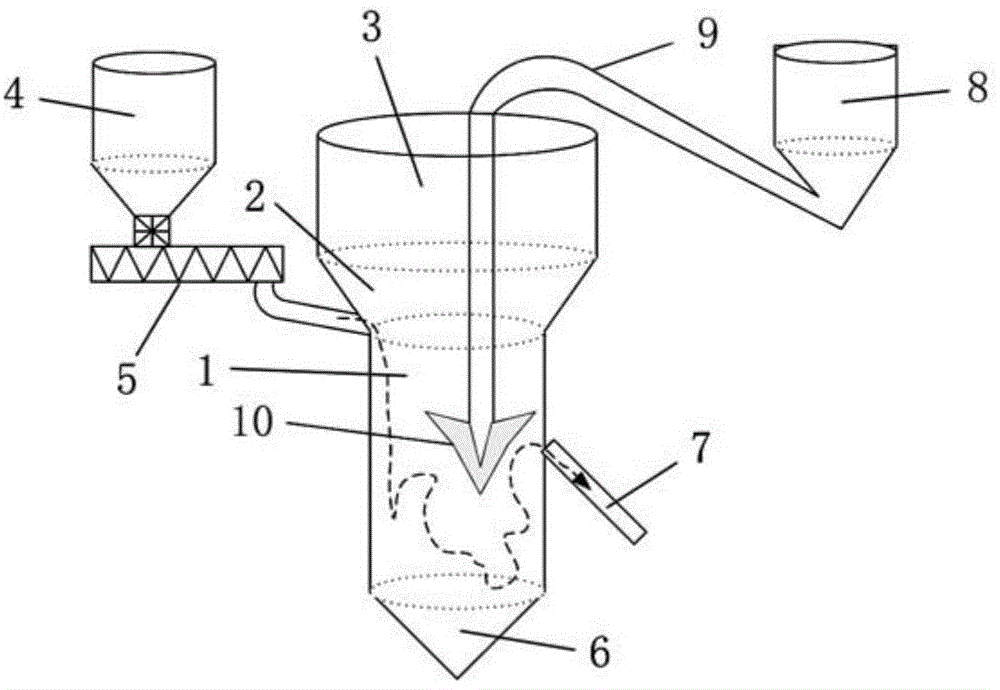

[0021] Hereinafter, the low temperature boiling chlorination method and the low temperature boiling chlorination furnace according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments. It should be noted that the carbide slag of the present invention is the blast furnace slag obtained by blast furnace smelting of ilmenite (such as vanadium-titanium magnetite) and then formed after carbonization. In one embodiment, the carbide slag contains 6-14wt% of titanium carbide (TiC). In addition, titanium tetrachloride (TiCl 4 ) is liquid at normal temperature (for example, 26°C), and its boiling point is 136.2°C.

[0022] figure 2 is a schematic diagram of a low temperature boiling chlorination furnace of an exemplary embodiment of the present invention. Such as figure 2 As shown, in an exemplary embodiment of the present invention, the low-temperature fluidized chlorination furnace comprises a reaction section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com