Sealing strip structure for sealing

A sealing strip and strip-shaped technology, applied in heating/cooling equipment, air treatment equipment, transportation and packaging, etc., can solve the problems that affect the use effect of air conditioners, and the sponge cannot achieve sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

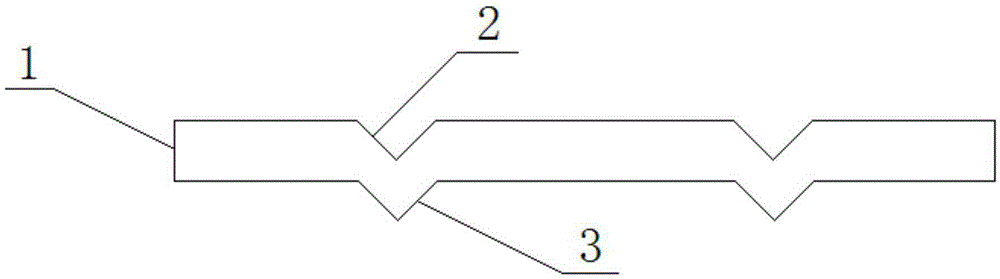

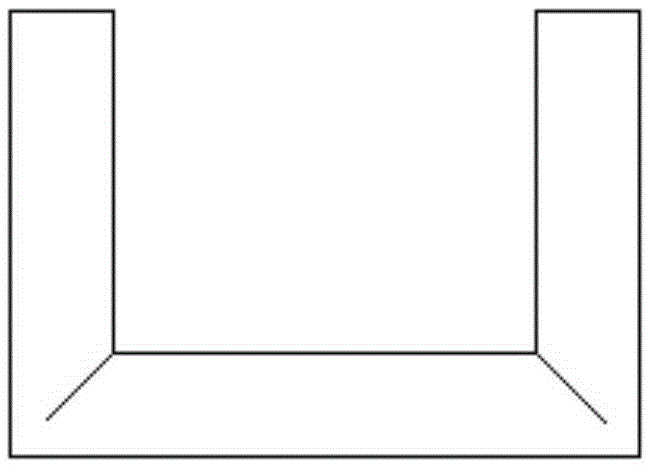

[0016] figure 1 It is a schematic diagram of the structure of the sealing strip used for sealing in the present invention, figure 2 It is a structural schematic diagram of the sealing strip structure used for sealing according to the present invention. Depend on Figure 1-Figure 2 Combining the structures shown, it can be seen that in this kind of sealing strip structure for sealing, the sealing strip is in the shape of a long strip, and the material of the sealing strip is sponge. The two end faces in the length direction of the sealing strip are glued surfaces 1, one side of the sealing strip is provided with several notches 2 in sequence, and the other side opposite to the side with V-shaped notches 2 is provided with several V-shaped notches. The protrusion 3, and the position of the notch 2 corresponds to the position of the protrusion 3 one by one.

[0017] The angle range of the notch 2 is 30°-120°, further, the angle of the notch 2 is preferably 90°.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com