A kind of velvet tooling

A tooling and fleece pasting technology, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of large investment in electrostatic equipment, harsh material selection of glue and fluff, and irregular flocking areas, so as to ensure stability and paste Fastness, the effect of reducing the risk of fluff polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in combination with specific embodiments.

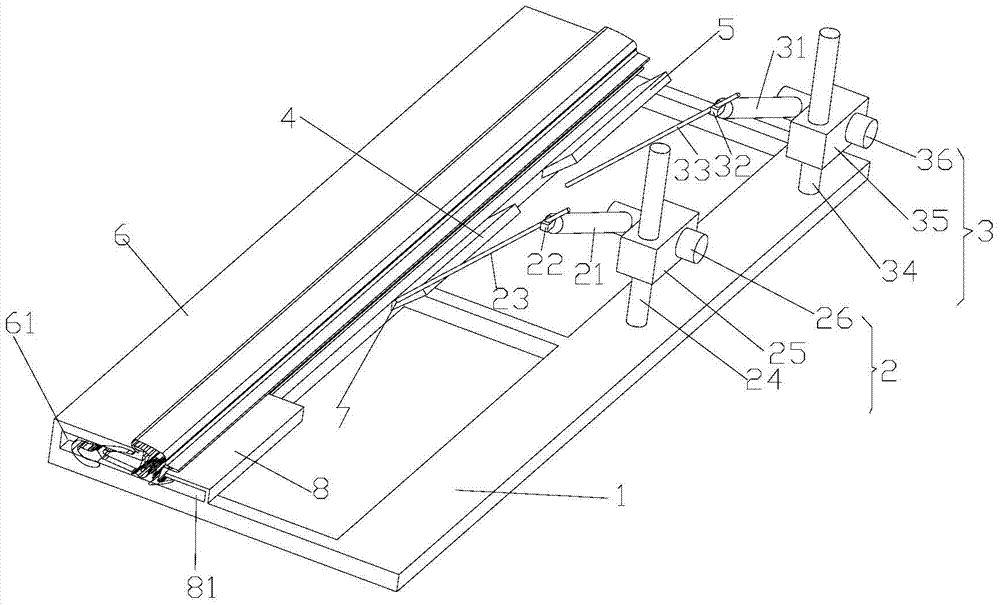

[0014] see figure 1 Shown is a schematic structural diagram of an embodiment of the present invention.

[0015] The pasted fleece frock of the present embodiment comprises:

[0016] A bottom frame 1, the upper surface of one side of the bottom frame 1 is provided with a first positioning frame 2 and a second positioning frame 3, and the middle part of the bottom frame is provided with a first positioning plate 4 and a second positioning plate inclined upward 5, and the other corresponding edge of the underframe is provided with a first limiting plate 6, and a first limiting space 61 for accommodating rubber strips is formed between the first limiting plate and the upper surface of the underframe;

[0017] The first positioning frame 2 is provided with a first rotating shaft 21, a first engaging portion 22 is provided on the first rotating shaft 21, and a first positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com