Vertical combined high-efficiency desulphurization deamination dust collector

A dust removal device and high-efficiency technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory dust removal effect and short service life, achieve low operation and maintenance costs, avoid secondary pollution, and be practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

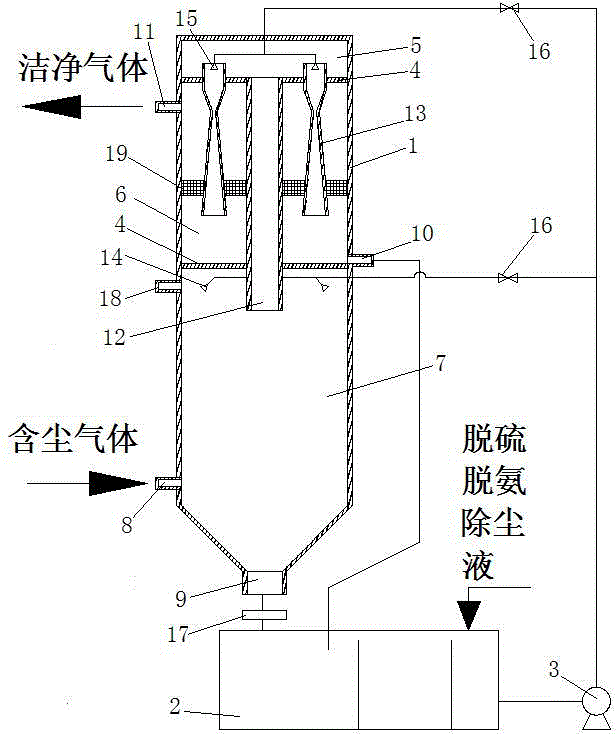

[0028] As shown in the accompanying drawing, a vertical combined high-efficiency desulfurization, deammonization and dust removal device includes a shell 1, a three-stage sewage sedimentation tank 2 and a circulation pump 3. The upper part of the shell 1 is cylindrical, and the lower part is inverted conical. Two upper and lower partitions 4 are arranged in the housing 1 to divide the inner space of the housing 1 into an upper diversion chamber 5, a middle and second-level Venturi dust removal chamber 6 and a lower-level cyclone dust removal chamber 7. The lower-level cyclone The left side below the dust removal chamber 7 is provided with an air inlet 8 along the tangential direction of the side wall, and the bottom is provided with a sew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com