copper base alloy

A copper-based alloy, high-quality technology, applied in the field of copper-based alloys, can solve the problems of adding Ni, etc., and achieve the effect of excellent stress corrosion cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

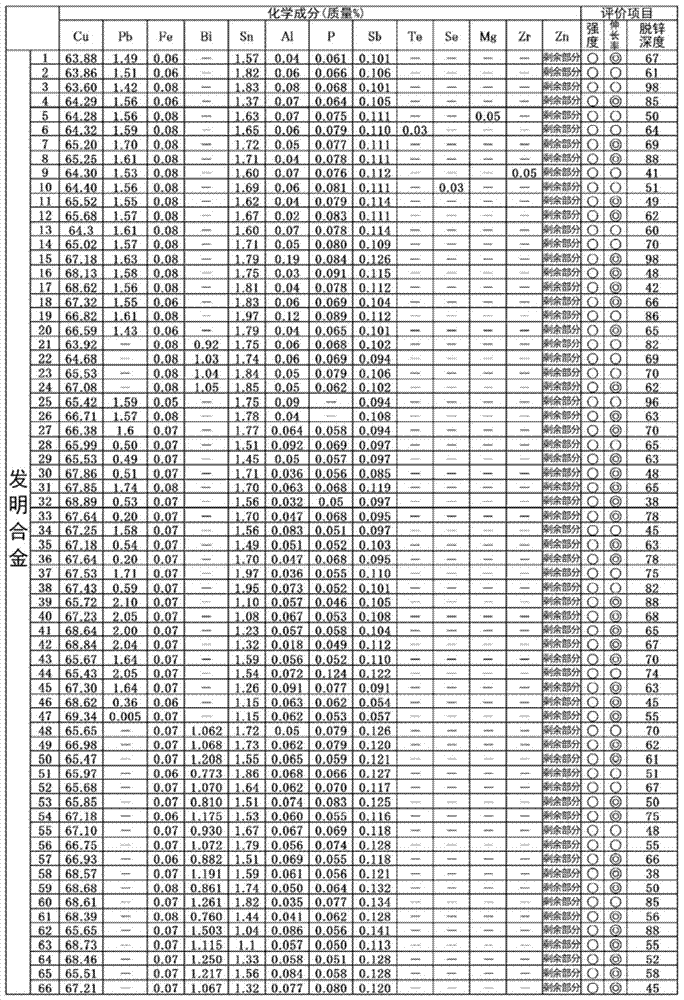

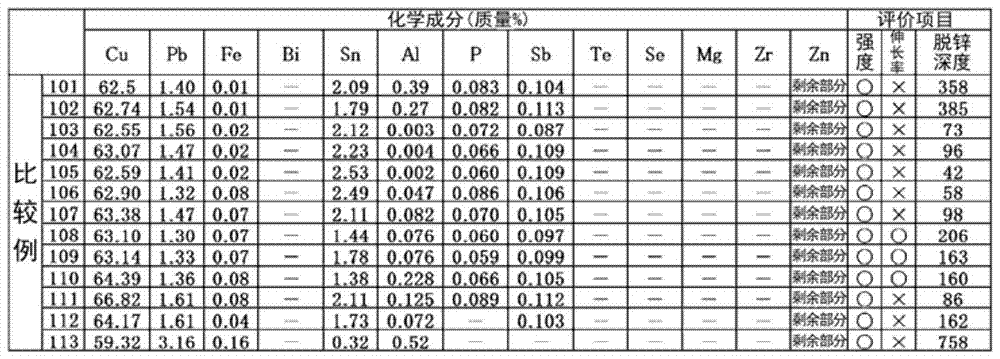

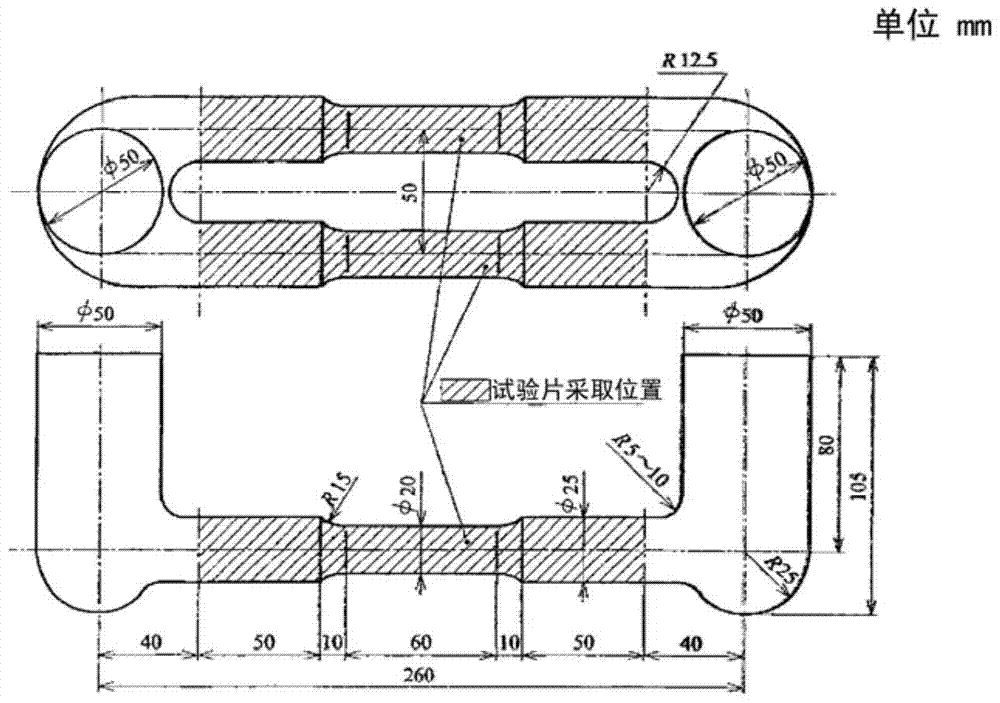

[0068] As a test piece, the figure 1 , figure 2 Molten metals with various alloy compositions as shown are adjusted, cast at about 1000°C and cooled (solidified) at image 3 In the JIS H5120 No. A test piece (sand mold) as shown, the frame was unframed and a sample was collected.

[0069] In addition, there are No. A, No. B, etc. among the casting molds constituting the test piece, but this time it was confirmed by the No. A test piece.

[0070] The remainder of the table, Zn, also contains unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com