An internal circulation oil cooling motor

An oil cooling and internal circulation technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of difficult radiation heat of the rotor, high current temperature rise, inability to meet high-efficiency cooling, etc., to achieve good cooling effect, The effect of reducing resistance and solving the difficulty of rotor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

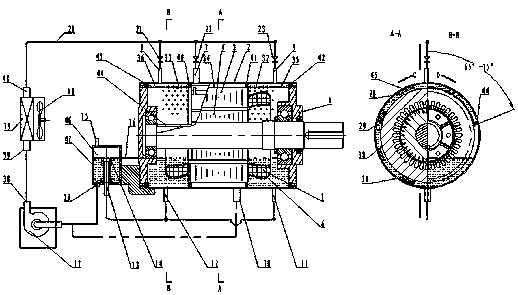

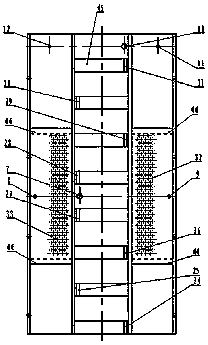

[0010] Below in conjunction with the embodiment figure 1 and figure 2 The present invention is further elaborated.

[0011] refer to figure 1 , an internal circulation oil cooling motor, including a closed motor body 1, a cooling oil level regulator 38, a cooling oil delivery pump assembly 17, a heat exchanger 19, a cooling fan 18, a cooling oil delivery pipe 20, and a first valve 21. The second valve 22 and the third valve 23, the cooling oil level regulator 38 is fixed on the casing 2 of the closed motor body 1, and the liquid level regulator casing 36, the external thread oil inlet 13 , Internal thread overflow liquid level adjusting nut 14, the third oil outlet 37 and vent 15 are formed. Its external thread oil inlet 13 is connected with the first oil outlet 11 and the second oil outlet 12 on the enclosed motor housing 2 . The oil inlet of the cooling oil delivery pump assembly 17 is respectively connected to the cooling oil outlet 10 provided on the casing 2 of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com