Application of a three-dimensional ordered titanium dioxide nanotube array composite material doped with graphene

A nanotube array, three-dimensional ordered technology, applied in the development and research of new energy materials, achieves the effects of being beneficial to the reversible de/insertion process, simple preparation and modification process, and reducing internal resistance and charge transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

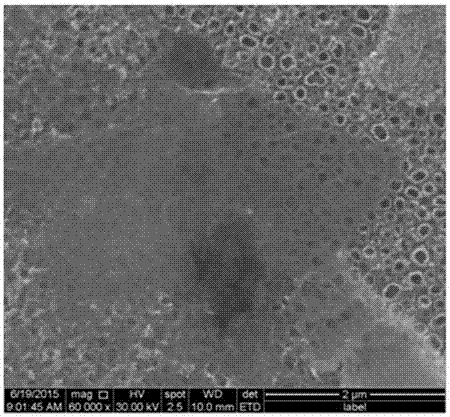

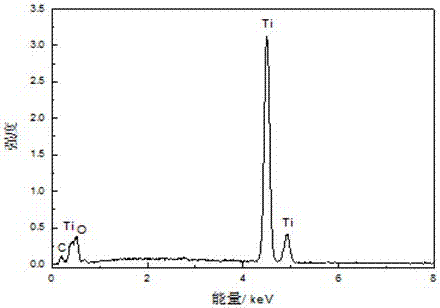

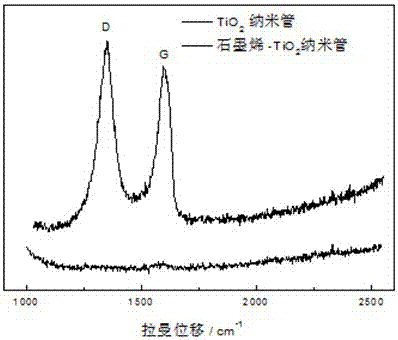

Image

Examples

Embodiment 1

[0022] In this embodiment, three-dimensional ordered TiO doped with graphene 2 Nanotube array composites used as working electrodes for lithium-ion batteries: three-dimensional ordered TiO doped with graphene directly without adding additional conductive agents and binders 2 The nanotube array composite negative electrode material is used as the working electrode, the lithium foil is used as the counter electrode and the reference electrode, the Celgard2500 film is used as the diaphragm, and the 1mol / L LiPF 6 The mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and dimethyl carbonate (DMC) is the electrolyte, in which the volume ratio of EC, DEC and DMC is 1:1:1, filled with high-purity A button-type simulated lithium-ion battery is assembled with lithium foil in an argon glove box, and its charge / discharge performance and cycle stability are tested by constant current charge / discharge method.

[0023] The graphene-doped three-dimensional ordered TiO described in t...

Embodiment 2

[0025] In this embodiment, three-dimensional ordered TiO doped with graphene 2 Nanotube array composites used as working electrodes for lithium-ion batteries: three-dimensional ordered TiO doped with graphene directly without adding additional conductive agents and binders 2 The nanotube array composite negative electrode material is used as the working electrode, the lithium foil is used as the counter electrode and the reference electrode, and the Celgard2400 film is used as the diaphragm, and the 1mol / L LiPF 6 The mixture of ethylene carbonate (EC) and diethyl carbonate (DEC) is the electrolyte, wherein the volume ratio of EC and DEC is 1:1, and it is assembled with lithium foil in a glove box filled with high-purity argon. Button-type simulated lithium-ion battery, test its charge / discharge performance and cycle stability by constant current charge / discharge method.

[0026] The graphene-doped three-dimensional ordered TiO described in this embodiment 2 Nanotube array co...

Embodiment 3

[0028] In this embodiment, three-dimensional ordered TiO doped with graphene2 Nanotube array composites used as working electrodes for lithium-ion batteries: three-dimensional ordered TiO doped with graphene directly without adding additional conductive agents and binders 2 The nanotube array composite negative electrode material is used as the working electrode, the lithium foil is used as the counter electrode and the reference electrode, the Celgard2325 film is used as the diaphragm, and the 1mol / L LiPF 6 The mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and dimethyl carbonate (DMC) is the electrolyte solution, in which the volume ratio of EC, DEC and DMC is 1:1:1, filled with high-purity A button-type simulated lithium-ion battery is assembled with lithium foil in an argon glove box, and its charge / discharge performance is tested by a constant current charge / discharge method ( Figure 4 ) and cycle stability performance, and an AC impedance test was performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com