A cylindrical battery case

A technology for cylindrical batteries and battery shells, which is applied to battery boxes/covers, battery pack components, battery box/cover materials, etc., and can solve the problems of detachment of winding core and tabs, poor lateral stop effect, and disconnection of welding points, etc. problems, to achieve the effect of improving cycle performance, avoiding solder joint disconnection, and inhibiting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

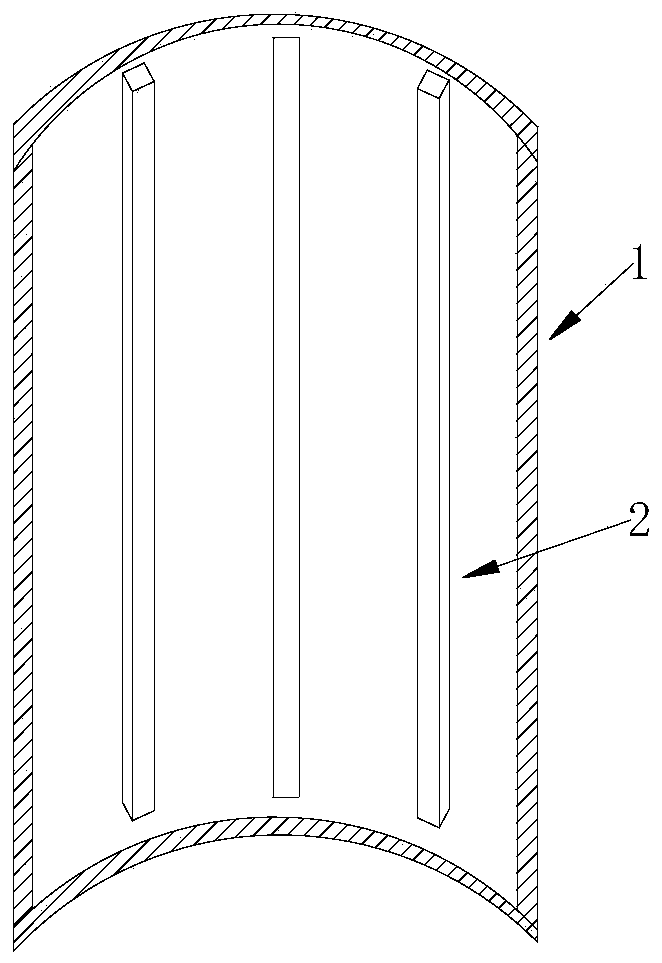

[0018] To make 32131 type (diameter 32mm, height 131mm) cylindrical battery, the front sectional view of the cylindrical shell used is as follows figure 1 shown. The battery case wall (1) is made of aluminum with an inner diameter of 30.8 mm. There are 6 strip-shaped polymer linings (2) attached to the battery case wall (1). The strip-shaped polymer liners (2) are evenly distributed on the battery On the inner side of the shell wall (1), the strip-shaped polymer lining (2) has a thickness of 0.05mm, a width of 4mm, and a length of 123mm, and the distance between the two ends of the strip-shaped polymer lining (2) is from the battery shell wall ( 1) The distance between the ends on the same side is 4mm. The strip-shaped polymer lining (2) is made of a blend of PAN (polyacrylonitrile) and PMMA (polymethyl methacrylate). Use LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary positive electrode material is combined with artificial graphite negative electrode to make a cylindrical core w...

Embodiment 2

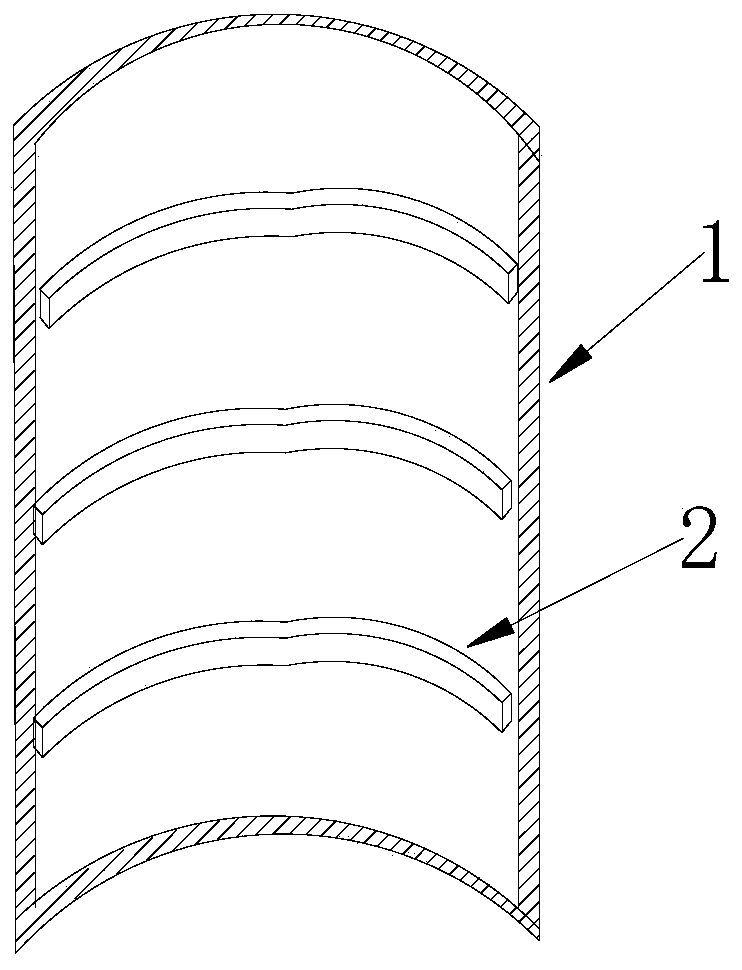

[0022] To make 42148 type (diameter 42mm, height 148mm) cylindrical battery, the front sectional view of the cylindrical shell used is as follows figure 2 shown. The battery case wall (1) is made of stainless steel with an inner diameter of 40.4 mm. There are three circular polymer linings (2) attached to the battery case wall (1), and the circular polymer linings (2) are evenly distributed On the inner side of the battery case wall (1), the annular polymer lining (2) has a thickness of 0.5 mm and a width of 8 mm, and the distance between the annular polymer lining (2) on both sides of the battery case wall ( 1) The distance between the ends on the same side is 10mm. The material of the annular polymer lining (2) is a blend of PAN (polyacrylonitrile) and PEO (polyethylene oxide). Use LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary positive electrode material is combined with the artificial graphite negative electrode to make a cylindrical core with a diameter of 38.2mm and put i...

Embodiment 3

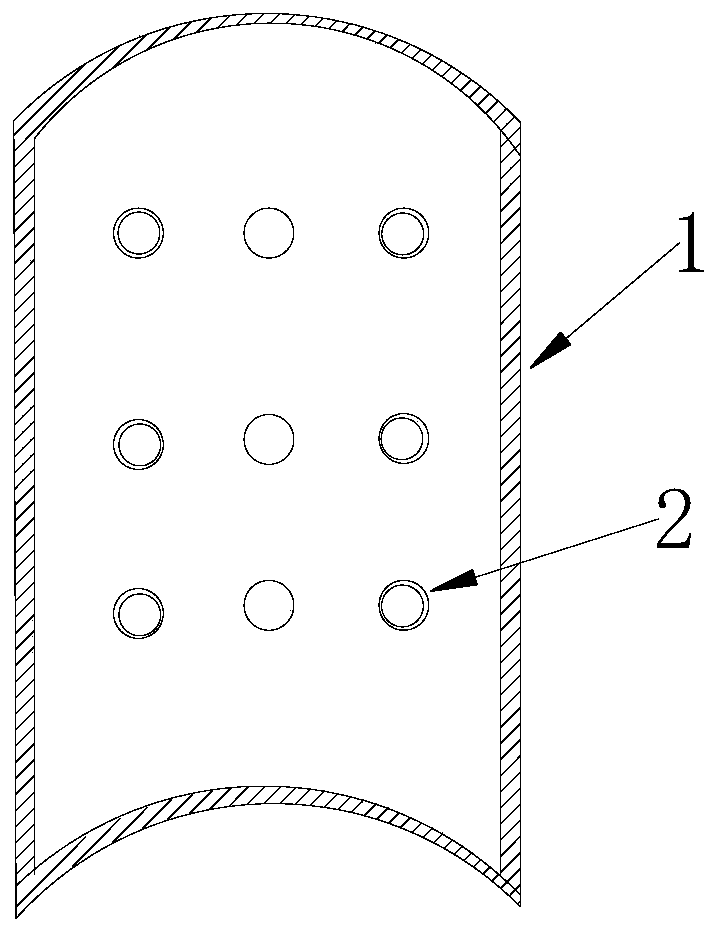

[0026] To make 42140 type (diameter 42mm, height 140mm) cylindrical battery, the front sectional view of the cylindrical shell used is as follows image 3 shown. The battery case wall (1) is made of ABS (acrylonitrile-styrene-butadiene copolymer), with an inner diameter of 38 mm. There are 18 dotted polymer linings (2) attached to the battery case wall (1). The dot-like polymer lining (2) is evenly distributed on the inner side of the battery case wall (1). The height of the dot-like polymer lining (2) is 0.15mm, and the diameter is 4mm. (2) The distance from the same side end of the battery case wall (1) is 10 mm. The material of the dot-like polymer lining (2) is a blend of PEO (polyethylene oxide) and PVAc (polyvinyl acetate). Use LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary positive electrode material is combined with the artificial graphite negative electrode to make a cylindrical core with a diameter of 37mm and put it into the above battery case and complete the subsequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com