Preparation method of high-magnetic-induction grain-oriented silicon steel EBSD samples

A high magnetic induction orientation and sample preparation technology, which is applied in the field of preparation of high magnetic induction orientation silicon steel EBSD samples, can solve the problems of sample occlusion, limited number of placed samples, and increased number of times of scanning electron microscope vacuuming, etc., to achieve simple operation, The Effect of Complexity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing an EBSD sample of high magnetic induction oriented silicon steel. The concrete steps of described preparation method are:

[0042] Step 1: Cutting one kind of high magnetic induction oriented silicon steel into original samples, the size of the original samples is RD×ND×TD=(9~11)×(0.3~4)×(4~6).

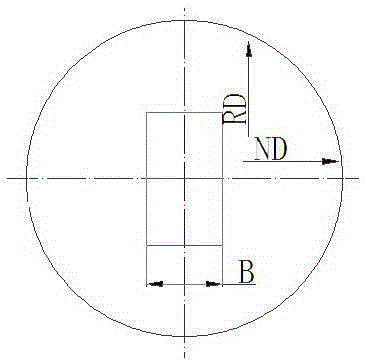

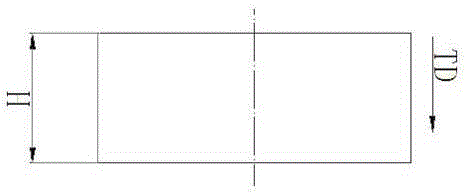

[0043] Step 2. Embed the original sample described in step 1 into the conductive mounting material to obtain the following: figure 1 and figure 2 The mosaic sample shown; the height H of the mosaic sample is 6-8 mm, and the cumulative thickness B of the original mosaic sample in the mosaic sample is ≤ 4 mm.

[0044] Step 3: Perform mechanical polishing on the mosaic sample, polish the target observation surface until the roughness Ra is 0.012-0.05 μm, obtain a mechanically polished sample, wash and dry it.

[0045] Step 4, cutting the cleaned and dried mechanically polished sample into a size of RD×ND×TD=(14~16)×(6~8)×(6~8) mm to obtain a cut sample; T...

Embodiment 2

[0050] A method for preparing an EBSD sample of high magnetic induction oriented silicon steel. The concrete steps of described preparation method are:

[0051] Step 1. Cut 2~5 different high magnetic induction oriented silicon steels into original samples respectively. The size of a single original sample is RD×ND×TD=(9~11)×(0.3~0.8)×(4~ 6).

[0052] Step 2. Embed the original sample described in step 1 into the conductive mounting material to obtain the following: figure 1 and figure 2 The mosaic sample shown; the height H of the mosaic sample is 6-8 mm, and the cumulative thickness B of the original mosaic sample in the mosaic sample is ≤ 4 mm.

[0053] Step 3: Perform mechanical polishing on the mosaic sample, polish the target observation surface until the roughness Ra is 0.012-0.05 μm, obtain a mechanically polished sample, wash and dry it.

[0054] Step 4: Cut the cleaned and dried mechanically polished sample into a size of RD×ND×TD=(14~16)×(6~8)×(6~8) mm, and obt...

Embodiment 3

[0059] A method for preparing an EBSD sample of high magnetic induction oriented silicon steel. The concrete steps of described preparation method are:

[0060] Step 1. Cut 6~8 kinds of high magnetic induction oriented silicon steel into original samples respectively. The size of a single original sample is RD×ND×TD=(9~11)×(0.3~0.5)×(4~ 6).

[0061] Step 2. Embed the original sample described in step 1 into the conductive mounting material to obtain the following: figure 1 and figure 2 The mosaic sample shown; the height H of the mosaic sample is 6-8 mm, and the cumulative thickness B of the original mosaic sample in the mosaic sample is ≤ 4 mm.

[0062] Step 3: Perform mechanical polishing on the mosaic sample, polish the target observation surface until the roughness Ra is 0.012-0.05 μm, obtain a mechanically polished sample, wash and dry it.

[0063] Step 4, cutting the cleaned and dried mechanically polished sample into a size of RD×ND×TD=(14~16)×(6~8)×(6~8) mm to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com