Electro-hydraulic driving system for sluice valve and sluice valve

A driving system and gate valve technology, applied in valve details, valve devices, engine components, etc., can solve the problems of oil cylinder or structure being damaged, accumulator filled with liquid, and unable to implement, so as to prevent water hammer phenomenon and facilitate system layout , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

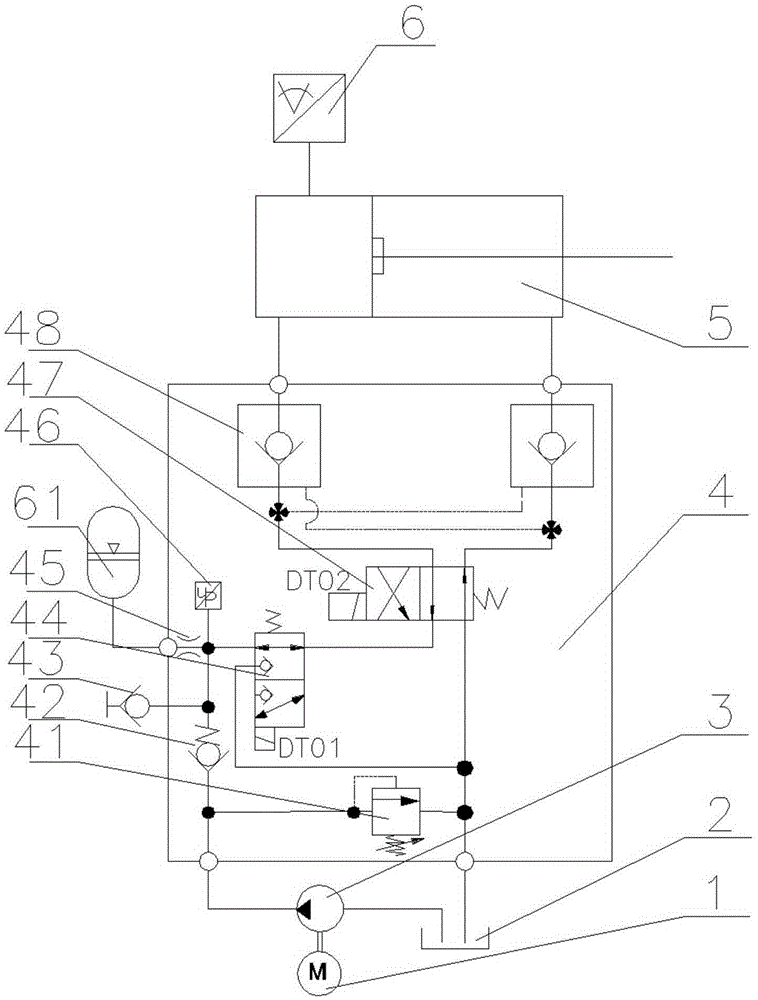

[0022] The present invention is described in detail below in conjunction with accompanying drawing, as figure 1 As shown, a gate valve electro-hydraulic drive system includes a motor 1, a hydraulic pump 3, an integrated control valve 4, an oil cylinder 5, an accumulator 61, a hydraulic oil tank and pipeline accessories 2, a monitoring and control system; an integrated control valve 4 Including overflow valve 41, one-way valve 42, quick connector 43, two-position three-way electromagnetic ball valve 44, throttle valve 45, pressure sensor 46, two-position four-way electromagnetic reversing valve 47, hydraulic control one-way valve 48, among which There are two hydraulically controlled one-way valves 48, one connected to the upper and lower chambers of the oil cylinder;

[0023] The hydraulic pump 3 is driven by the motor 1, its oil suction port is connected with the oil tank 2, the pressure oil port is connected in parallel to protect the overflow valve 4a, the oil return port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com