Ultrasonic metering ball valve

An ultrasonic and ball valve technology, applied in the field of ultrasonic metering ball valves, achieves the effects of high measurement accuracy, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

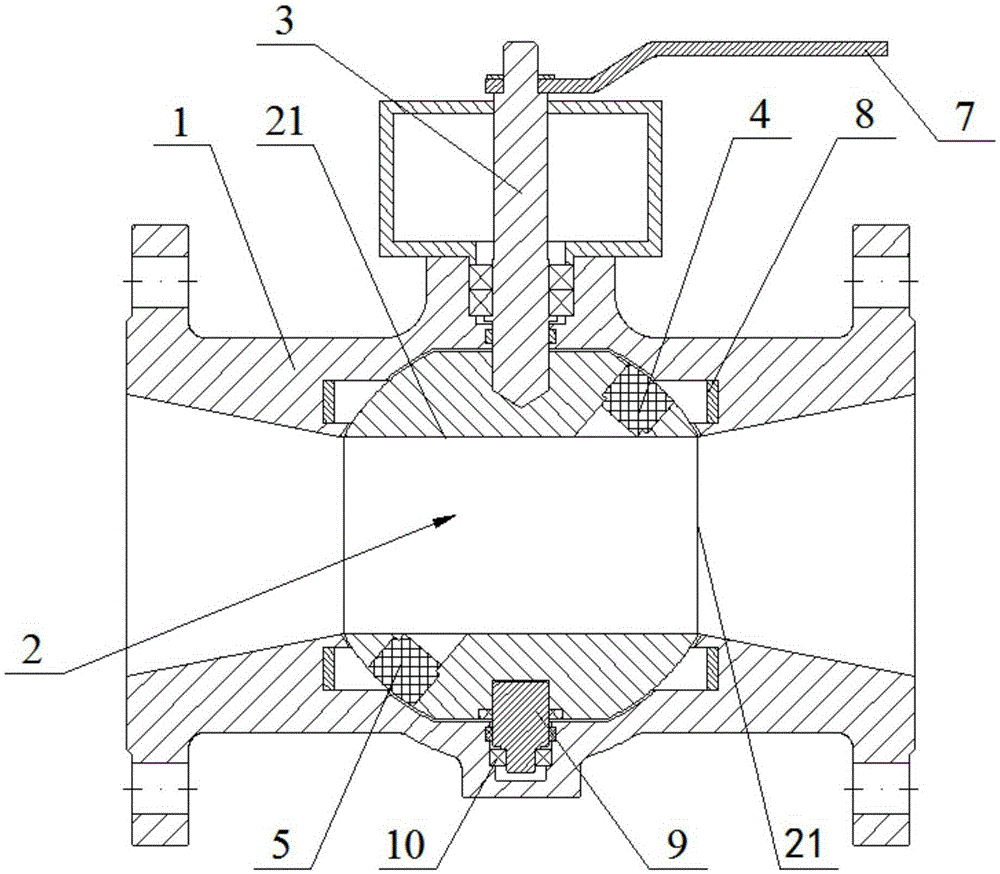

[0027] Such as figure 1 The ultrasonic metering ball valve shown includes a valve body 1, a ball core 2 disposed in the valve body 1, and a valve stem 3 that drives the ball core 2 to rotate; the ball core 2 is provided with a fluid through hole 21, and the inner wall of the fluid through hole 21 There is an ultrasonic sensor for measuring fluid flow. The ultrasonic sensor includes a pair of sending sensors 4 and receiving sensors 5 , and the sending sensors 4 and receiving sensors 5 are symmetrically arranged around the center point of the fluid through hole 21 .

[0028] The upper end of the valve stem 3 is provided with a drive motor (not shown) or a handle 7 for driving the valve stem 3 to rotate. It also includes a control part (not shown in the figure) and a power supply part (not shown in the figure); the control part includes a single-chip microcomputer (not shown in the figure) and a drive motor control module (not shown in the figure); the standard flow data entered...

Embodiment 2

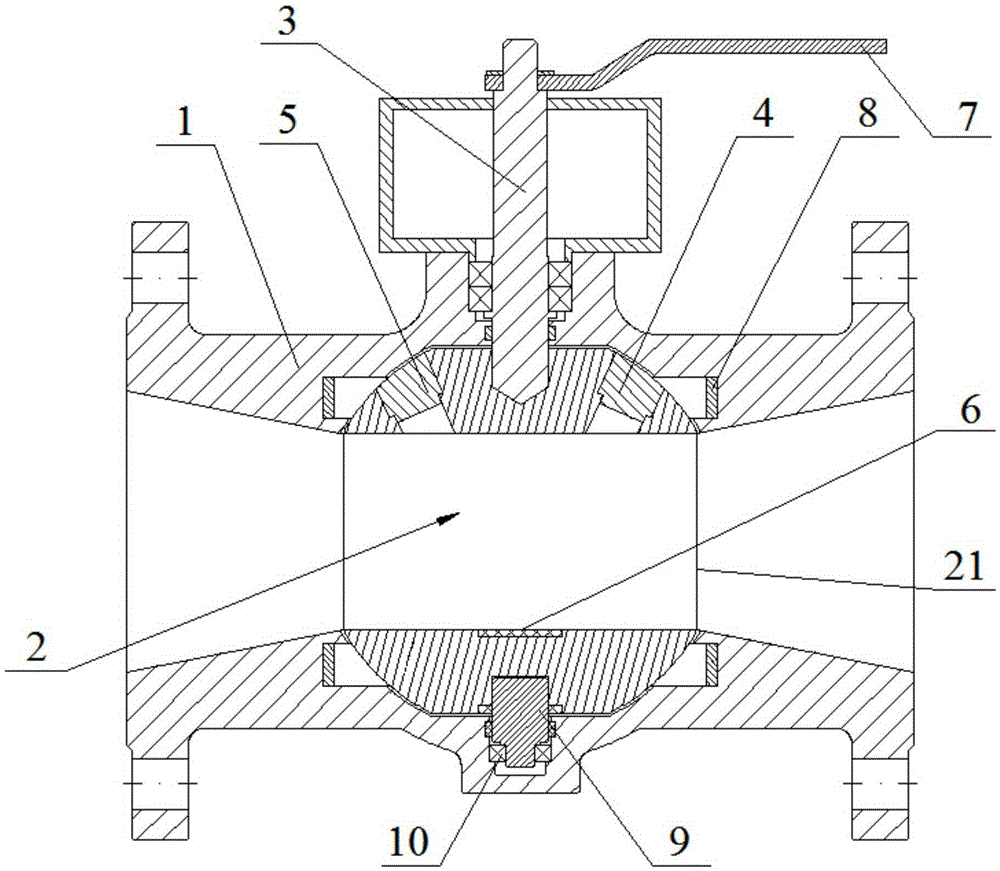

[0031] Such as figure 2 As shown, the structure of the ultrasonic metering ball valve in this embodiment is basically the same as in Embodiment 1, the difference is that the ultrasonic sensor includes a group of sending sensors 4, receiving sensors 5 and reflective sheets 6, and the ultrasonic waves emitted by the sending sensors 4 are reflected by the reflective sheets 6 To the receiving sensor 5; the transmitting sensor 4 and the receiving sensor 5 are arranged mirror-symmetrically with the axial section of the fluid through hole 21 or the section perpendicular to the axis, and the reflective sheet 6 is arranged between the transmitting sensor 4 and the receiving sensor 5 and the reflective sheet 6 The reflective surface is opposite to the transmitting end of the transmitting sensor 4 and the receiving end of the receiving sensor 5 . The included angle between the extended line of the midline of the sending sensor 4 and the vertical line of the reflective sheet 6 is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com