Giant vertical shield machine

A shield machine, giant technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of insufficient use of underground space, easy fire, unsafe, etc., to improve construction quality, reduce construction costs, ensure The effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

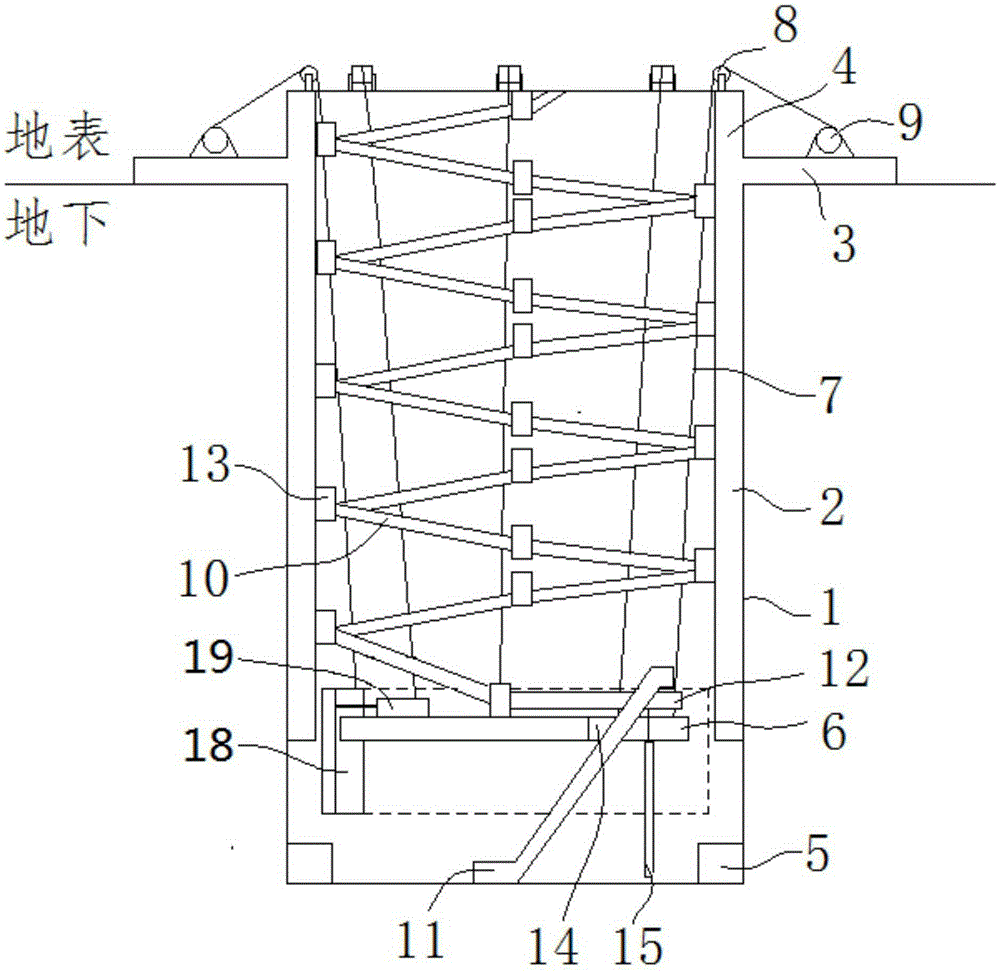

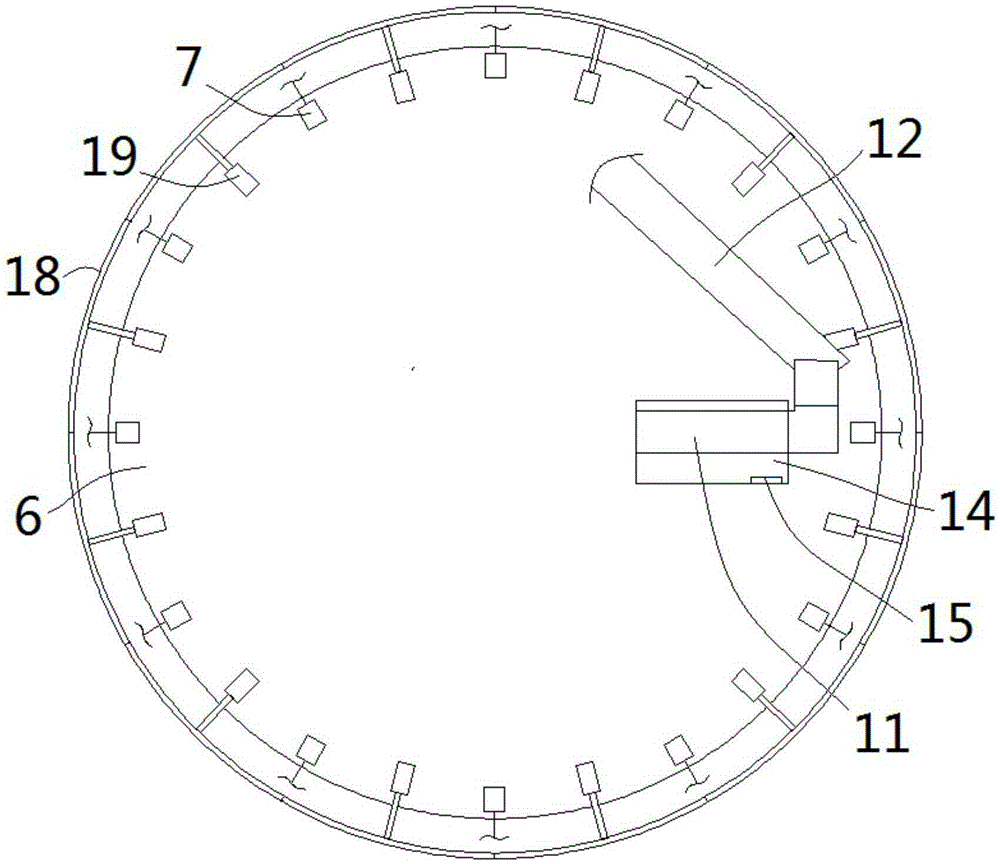

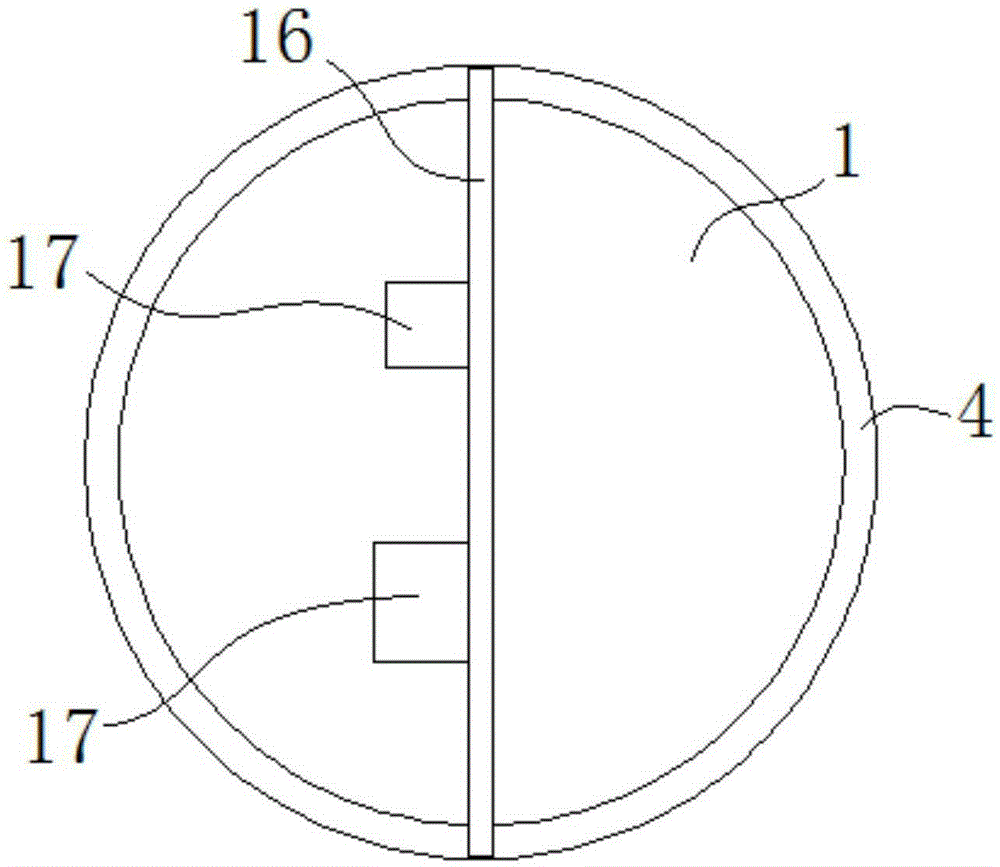

[0024] Such as Figure 1-2 As shown, a giant vertical shield machine described in the embodiment of the present invention is used to excavate the foundation pit 1 of the engineering foundation, or the foundation pit 1 of the underground building. The shape of the foundation pit 1 is a cylinder, and the foundation pit 1 is cylindrical. The diameter length of the pit 1 is 20-200M, the side wall of the foundation pit 1 is provided with a reinforced concrete layer 2, and the top of the foundation pit 1 is provided with an outwardly bent reinforced concrete fixed layer 3, and the foundation pit The top of 1 is also provided with an upwardly extending reinforced concrete extension layer 4, the reinforced concrete extension layer 4, the reinforced concrete fixed layer 3 and the reinforced concrete layer 2 are integrally structured.

[0025] Also includes the following structures:

[0026] The excavation mechanism includes a plurality of evenly distributed milling machines 5, the mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com