Formwork support system for steel frame structure cast-in-place concrete floorslabs

A formwork support and concrete technology, which is applied to the preparation of building components on site, formwork/formwork/work frame, building construction, etc., can solve the problems of slowing down construction progress, slow construction progress, and large steel consumption, and achieve faster Construction progress, effect of reducing on-site workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

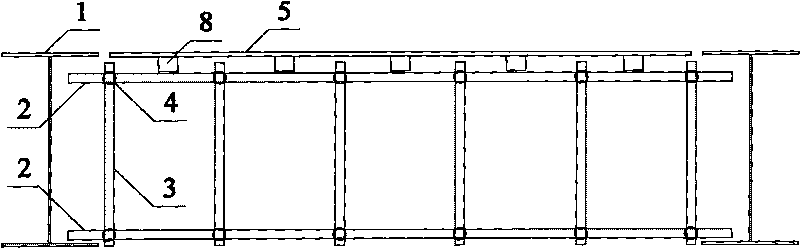

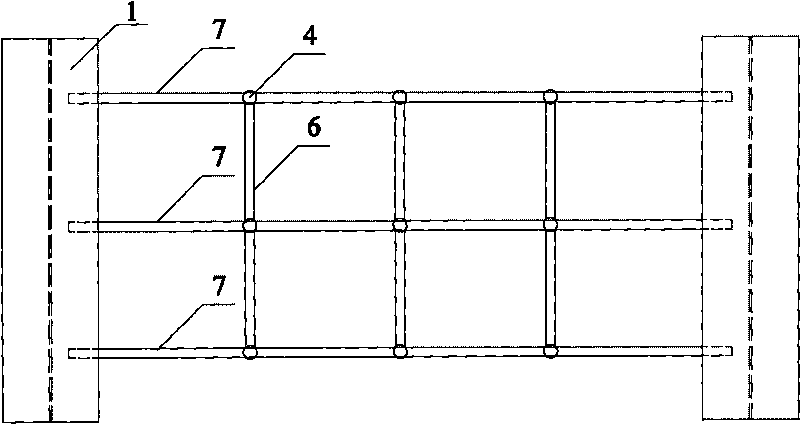

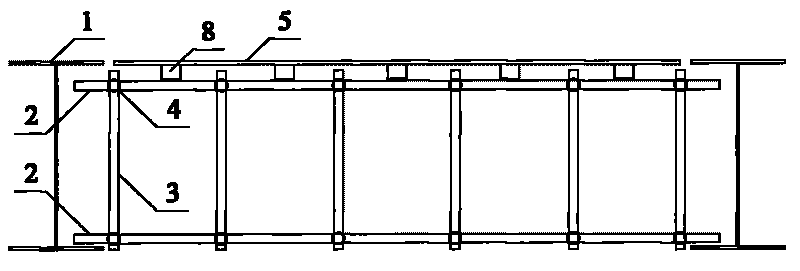

[0018] The formwork support system for cast-in-place concrete slabs of steel frame structures includes I-shaped section beams 1, horizontal scaffolding steel pipes 2, vertical scaffolding steel pipes 3, steel pipe fasteners 4, wooden formwork 5, tie rod steel pipes 6, and corrugated wood 8; Two horizontal scaffolding steel pipes 2 and multiple vertical scaffolding steel pipes 3 are connected by steel pipe fasteners 4 to form a scaffolding steel pipe truss 7. Scaffolding steel pipe trusses 7 with more than 2 poles are connected with more than two tie rod steel pipes 6 through steel pipe fasteners 4. Scaffolding steel pipes The lower end of the truss 7 is placed on the lower flange of the I-shaped cross-section beam 1, the upper end of the steel pipe truss 7 of the scaffolding is placed with corrugated wood 8, and the wooden formwork 5 is placed on the corrugated wood 8.

[0019] When the distance between two adjacent I-shaped cross-section beams 1 is less than 3 meters, the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com