Construction method of steel-concrete composite storey

A construction method and concrete layer technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of slow construction speed and heavy on-site workload, and achieve fast construction speed and on-site Small workload, simple and reliable connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

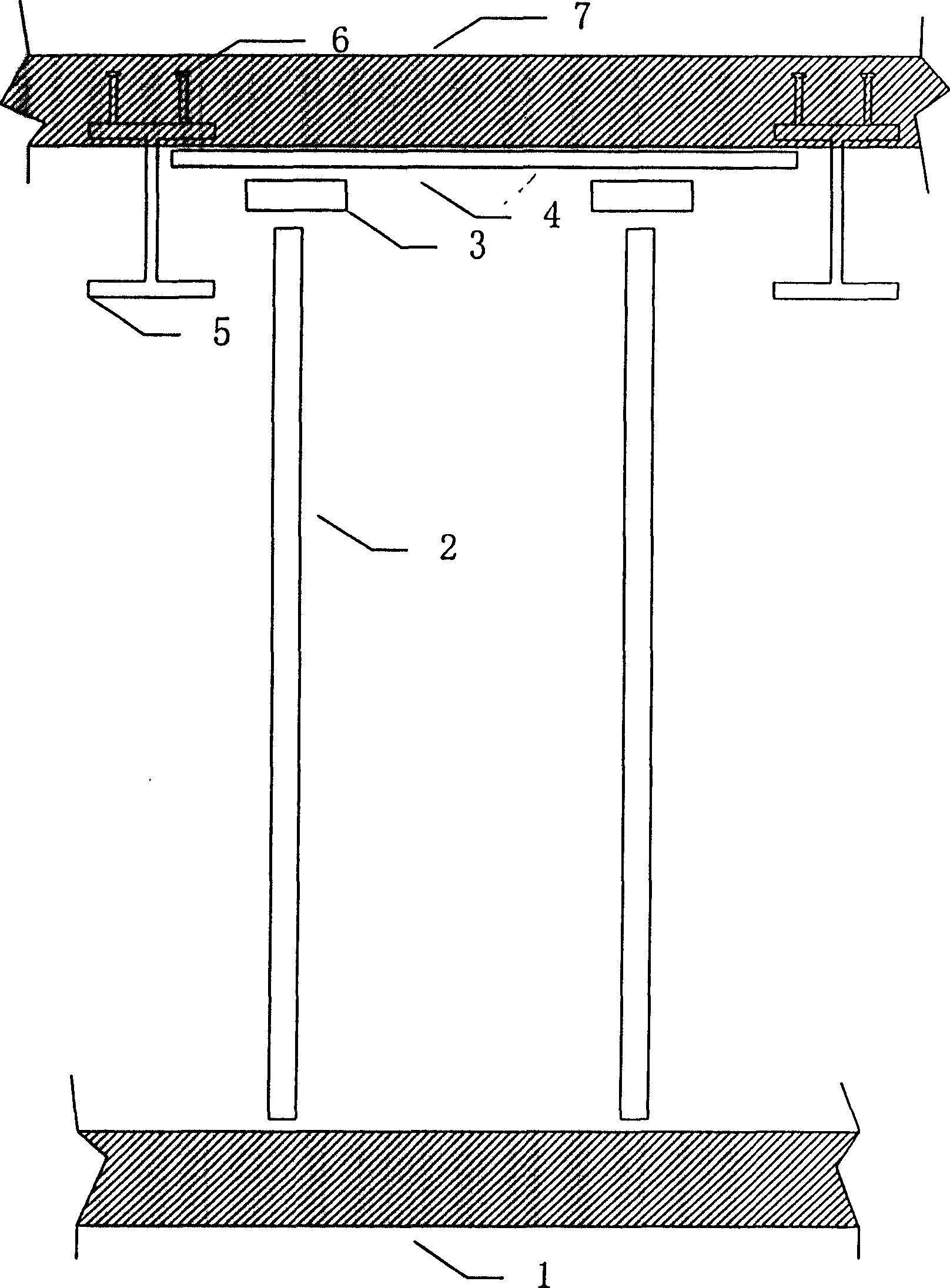

[0018] Such as figure 2 As shown, the method steps are:

[0019] (1) Pre-drilling connection holes 8 on the web of the steel beam 5;

[0020] (2) The steel beam 5 is connected with the grooved angle steel bracket 10 through the connecting hole 8 of its web by the connecting piece 9 consisting of bolts and nuts;

[0021] (3) Insert T-shaped steel 11 between the angle steel brackets 10 as a cross brace;

[0022] (4) Lay a reusable formwork 4 on the T-shaped steel cross brace 11, and the formwork 4 adopts a standard composite plate of 1220 × 2400 × 15;

[0023] (5) tie steel bar and cast-in-place concrete layer on formwork 4;

[0024] (6) After the concrete reaches a certain strength, remove the connecting bolts 9, the angle steel brackets 10, the T-shaped joists 11 and the formwork 4 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com