Fabricated anti-explosion and explosion reduction wall and construction method thereof

A prefabricated and wall technology, applied in walls, protective buildings/shelters, building components, etc., can solve the problems of reinforced concrete wall damage, unreasonable design, insufficient blast resistance, etc., and achieve good energy absorption The effect of improving anti-explosion performance and excellent anti-explosion impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

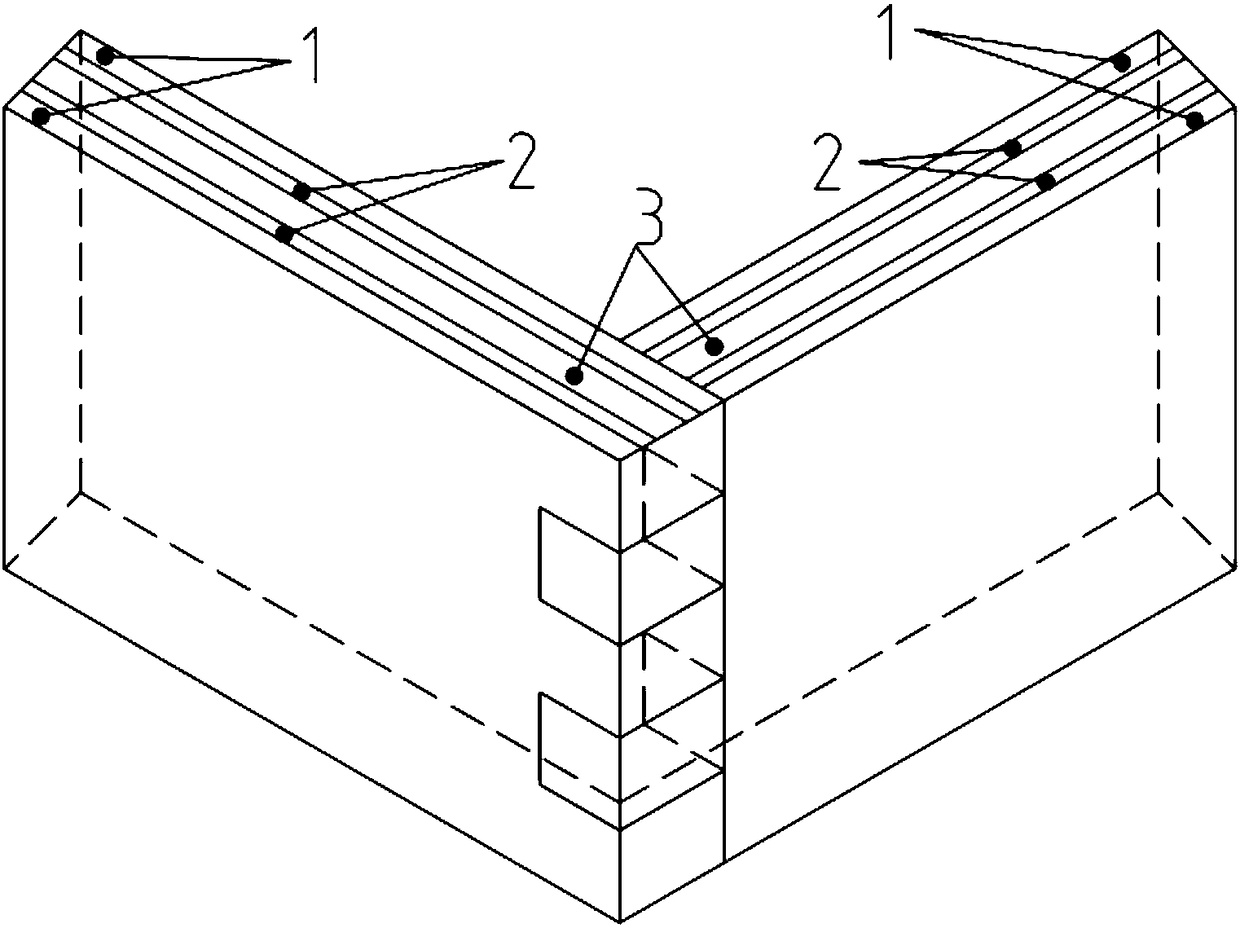

[0028] Such as Figure 1-3 As shown, a prefabricated anti-explosion and reduction wall of the present invention includes ordinary steel plate 1 , polyurethane foam aluminum 2 , steel fiber concrete prefabricated wall 3 and studs 4 . Ordinary steel plate 1, polyurethane foam aluminum 2, and steel fiber concrete fabricated wall 3 form a double-layer sandwich structure wall from outside to inside. Among them, the ordinary steel plate 1 is arranged on both sides of the prefabricated anti-explosion attenuation wall, the thickness of the ordinary steel plate 1 is 20 mm, and the surface of the ordinary steel plate is coated with a layer of zinc to avoid surface corrosion. The middle of the prefabricated anti-explosion reduction wall is a steel fiber reinforced concrete prefabricated wall 3, the thickness of the steel fiber rei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com