Steep coal-seam coal mining and transportation apparatus and coal mining and transportation method

A technology for mining and transporting coal and steep inclining, which is applied in mining equipment, earth-moving drilling, cutting machinery, etc. The effect of coal mining efficiency, improving total driving torque and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

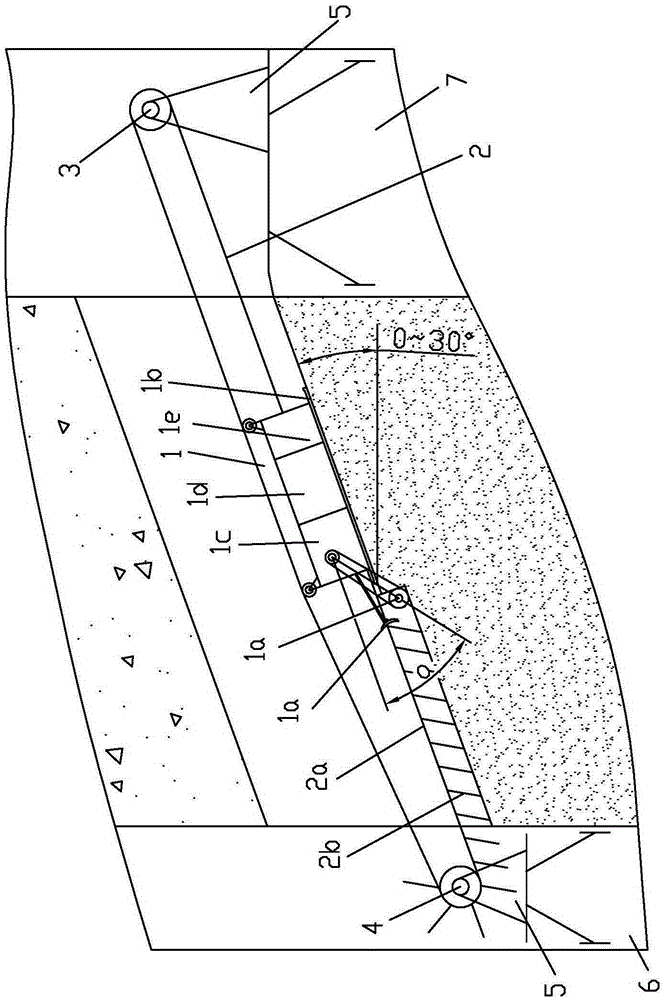

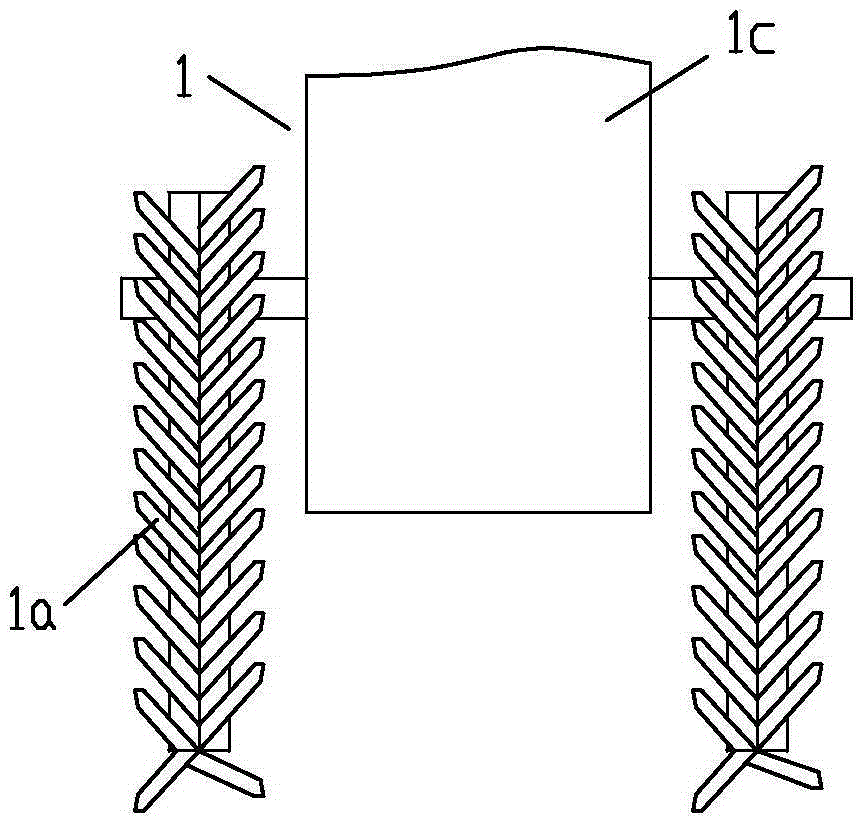

[0026] See Example 1 figure 1 , figure 2 , A coal mining and transporting device for steeply inclined coal seams, including a coal mining unit 1, a coal transport unit and a control system. The coal mining unit 1 is connected in series to an annular flexible traction member 2 through the front and rear ends. The output rotary drive unit 3 is driven, and the flexible traction member 2 is reversed by the reversing unit 4 to make the coal mining unit 1 move forward or backward. The back of the coal mining unit 1 is provided with a groove for intercepting the coal and rock mass below The coal mining part 1a; the flexible traction member 2 with a set length behind the coal mining unit 1 is in the structure of a traction chain 2a, and multiple rows of coal scrapers 2b that can penetrate into the groove are distributed along the length of the traction chain, The traction chain 2a and the coal scraper 2b constitute the coal transport unit.

[0027] Among them, the coal mining unit 1 als...

Embodiment 2

[0030] Example 2, see image 3 The coal intercepting part 1a is composed of two chain coal intercepting structures, and the two chain coal intercepting structures are respectively arranged on both sides of the reduction gear box 1b.

[0031] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0032] In the foregoing embodiments 1 and 2, the two supporting frames 5 can also be suspended by the cantilever beams provided on the flexible hydraulic shielding and supporting system in the working surface.

[0033] In the foregoing embodiments 1 and 2, the flexible traction element 2 adopts a traction chain structure as a whole, the rotary drive unit 3 drives the traction chain segment on the flexible traction element 2 through a driving sprocket, and the reversing unit 4 adopts a sprocket structure.

[0034] In the foregoing embodiments 1 and 2, the coal cutting portion 1a can also be composed of three, four or even more chain co...

Embodiment 3

[0035] Embodiment 3 is a coal mining and transporting method using the steeply inclined coal seam coal mining and transporting device described in embodiment 1 or 2, including the following steps:

[0036] The first step, coal mining: start the rotary drive unit 3 to rotate in the forward direction, and the coal mining unit 1 moves forward to cut the coal until the entire length of the coal seam of the working face is intercepted and then the machine stops;

[0037] The second step, coal transportation: start the rotary drive unit 3 to reverse rotation, the coal mining unit 1 retreats, the scraper on the traction chain 2a uses the groove formed by the coal cutting to transport the coal out of the working face.

[0038] Among them, it is necessary to form an open cut above the steeply inclined coal seam before mining; in the length direction of the coal seam, two inclined roadways 6 and 7 that are consistent with the inclination direction of the coal seam are formed according to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com