A drill pipe for a rotary drilling rig

A technology for rotary drilling rigs and drill pipes, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of downtime maintenance, cracks in plane annular welds, and long maintenance periods, and reduce the impact of connection reliability. , The effect of extending the period of trouble-free operation and reducing the frequency of downtime maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

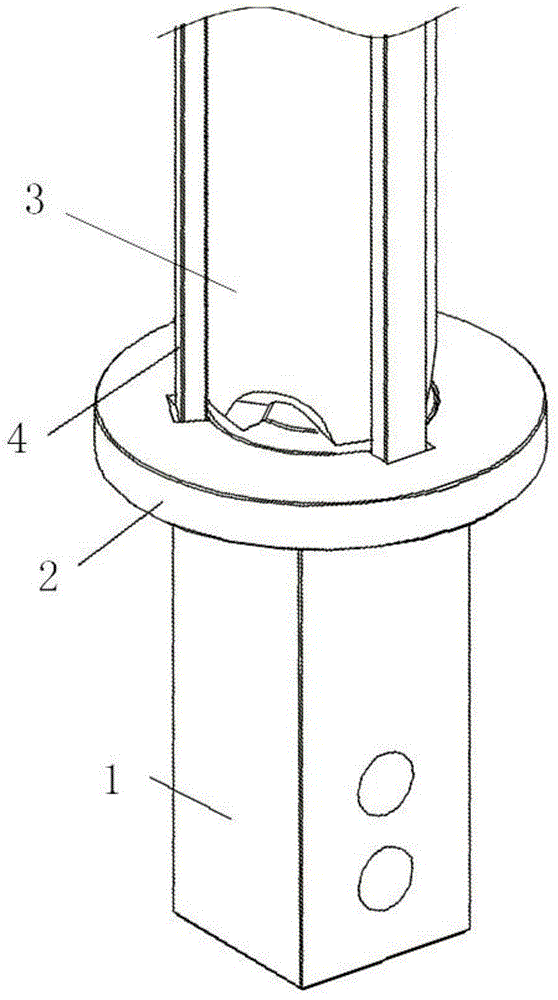

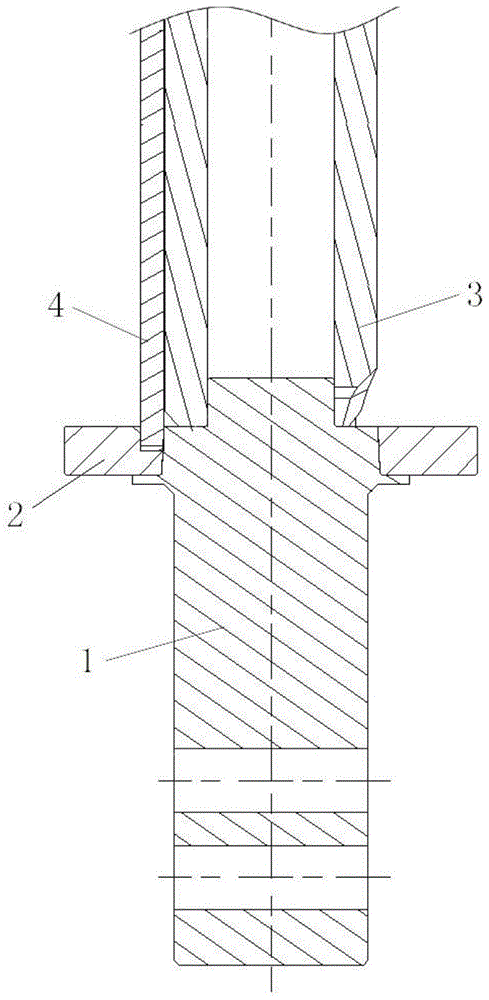

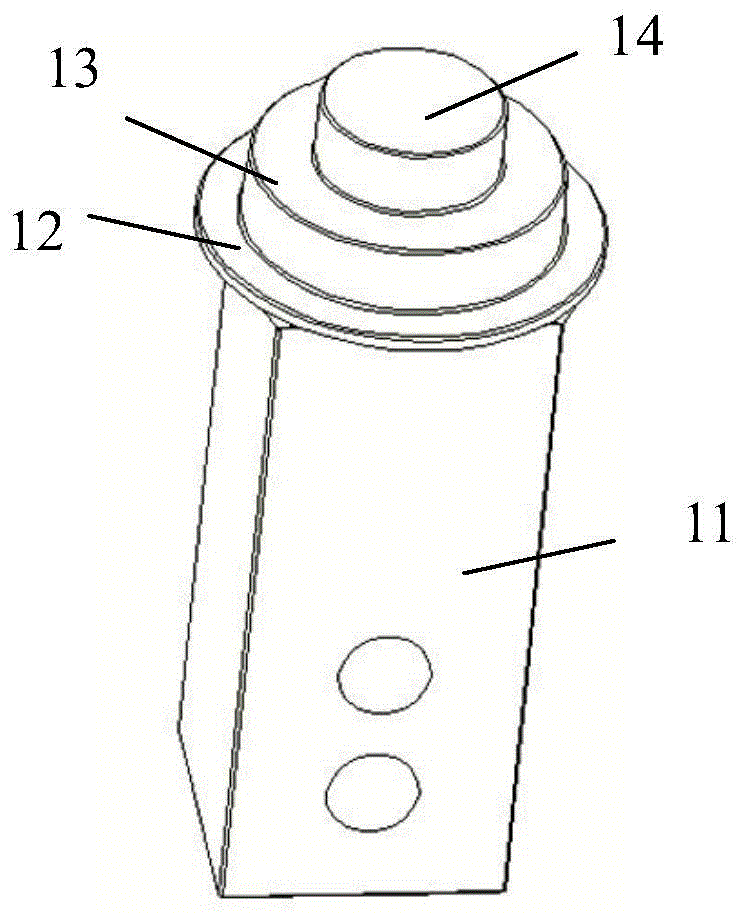

[0028] This embodiment is used for the drilling rod of rotary drilling machine, and its structure is as Figure 1 to Figure 5 Shown; including square head 1, main rod 3, carrying plate 2 and three key strips 4. The carrier plate 2 is provided with a carrier plate inner hole 21 . The square head 1 includes a square head body 11 , an installation platform 12 , a built-in platform 13 and a built-in platform 2 14 connected sequentially from bottom to top; The lower end surface of the carrier plate 2 is attached to the installation platform 12, the embedded platform 13 is embedded in the inner hole 21 of the carrier plate, and the embedded platform 2 14 extends to the rod cavity of the main rod 3; the outer surface of the embedded platform 13 The diameter and the outer diameter of the embedded platform two 14 are respectively matched with the inner diameter of the inner diameter of the carrier plate inner hole 21 and the inner diameter of the main rod 3 rod cavity. The height of ...

Embodiment 2

[0034] This embodiment is used for the drill rod of rotary drilling rig, including square head, main rod, bearing plate and a key bar; the bearing plate is provided with the inner hole of the bearing plate; the upper end of the square head extends through the inner hole of the bearing plate to the main rod The cavity is connected with the main rod; the inner hole of the carrying plate and the cavity of the main rod are respectively matched with the square head; the carrying plate is also provided with a concave position matching the key bar; the key bar is fitted and connected with the outside of the main bar, and the key The lower end of the bar stretches into the recess and connects with the bearing plate, so that the torque transmission between the main rod and the square head is jointly borne by the welding seam between the square head and the main rod, the bearing plate and the key bar. The main rod is connected to the square head by welding; the key strips are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com