Solid wood composite floor for geothermal and manufacturing method thereof

A technology of solid wood composite flooring and manufacturing methods, which is applied in the direction of building construction, construction, floors, etc., and can solve the problems of low heat conduction efficiency, poor dimensional stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Solid wood composite flooring for geothermal

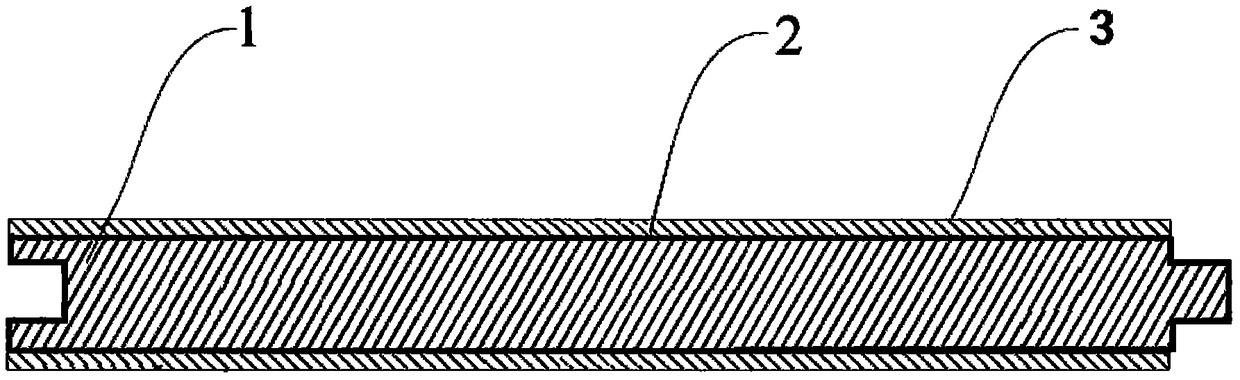

[0026] The solid wood composite floor for geothermal heating in a typical embodiment of the present invention comprises a solid wood floor substrate (1), a paint layer (3) and a copper film layer (2), and the solid wood composite floor substrate (1) and the paint layer (3) A copper film layer (2) with a thickness of 50 microns is arranged between them, and the surface of the copper film layer (2) is modified by nano-cellulose grafting.

[0027] The typical implementation steps of the manufacturing method of the composite geothermal solid wood floor of the present invention are as follows:

[0028] 1. Processing wood into a solid wood floor substrate belongs to the prior art;

[0029] 2. Immerse the solid wood floor substrate in step 1 into the copper plating solution for 15 minutes, the temperature of the copper plating solution is 50 degrees, and the copper plating solution is copper sulfate, ethylenediaminetet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com