Pipe gallery prefabricated member and assembled comprehensive pipe gallery

A technology of integrated pipe gallery and prefabricated parts, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of fragile connection structure, inconvenient transportation, hoisting, poor stability of assembly structure, etc., to achieve reliable sealing, on-site The effect of shortened construction period and stable structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

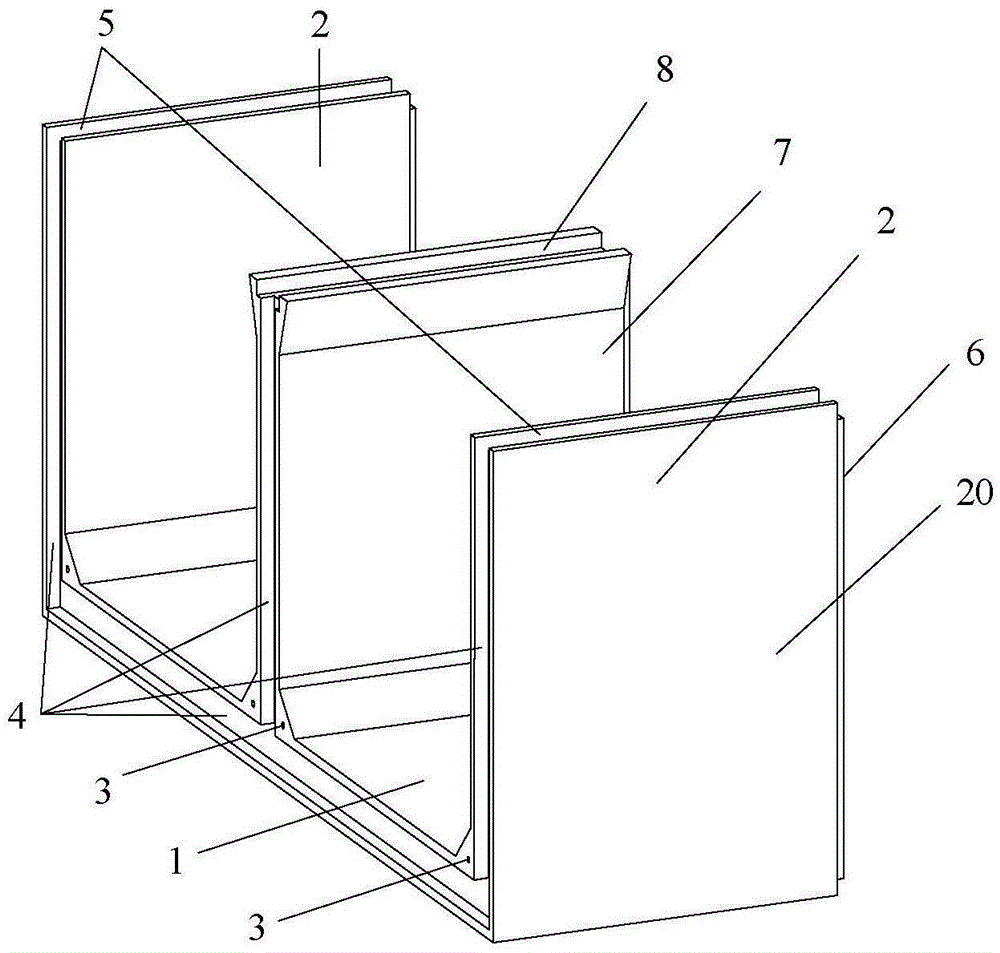

[0049] The pipe gallery prefabricated part of the present invention includes a base frame prefabricated part and a cover plate prefabricated part.

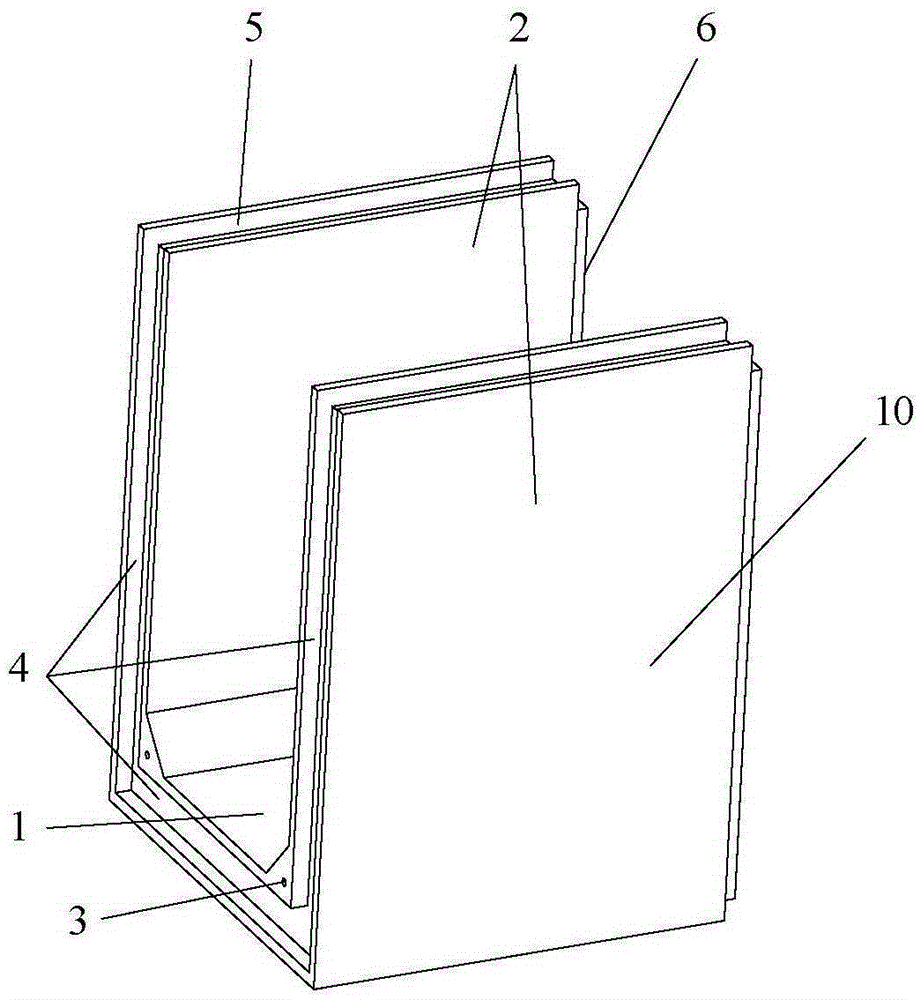

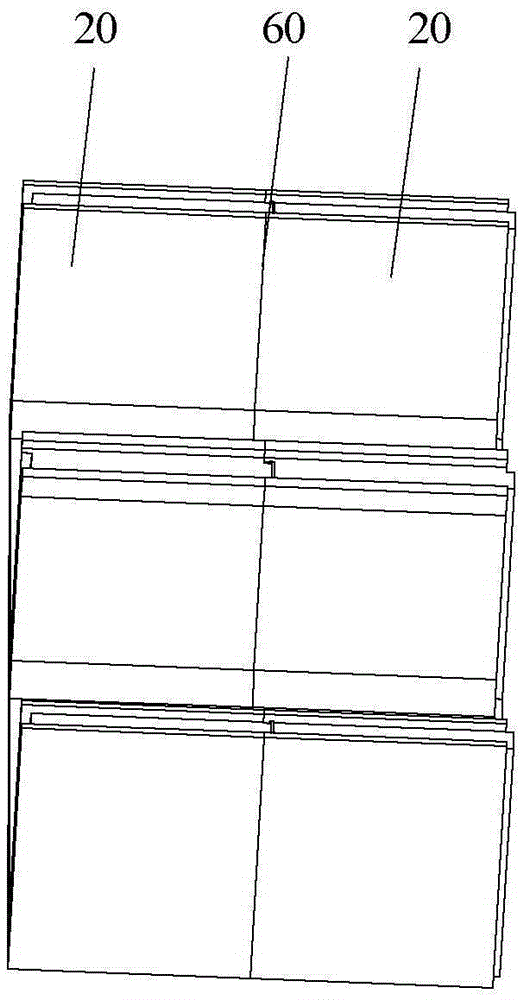

[0050] Such as figure 1 As shown, the chassis prefabricated part 10 includes a base plate 1, a vertical plate 2 extending upright from the base plate 1, reinforcements (such as steel bars, glass fibers, etc.) The prestressed steel cable hole 3 of the inner corner connected with the vertical plate 2. The prestressed steel cable holes 3 are used for prestressed connection of the longitudinally connected underframe prefabricated parts 10 through the prestressed steel cables during assembly.

[0051] The two vertical plates 2 and the bottom plate 1 form a U-shaped storage tank. figure 1 The chassis preform 10 shown is a single U-shaped tank chassis preform embodiment.

[0052] A groove A4 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com