Paper machine system and negative ion control method thereof

An anion control, paper machine technology, applied in the papermaking field, can solve the problems affecting the stability of the wet end, and achieve the effect of improving the running performance and the efficiency of chemical use, improving the efficiency and reducing the production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

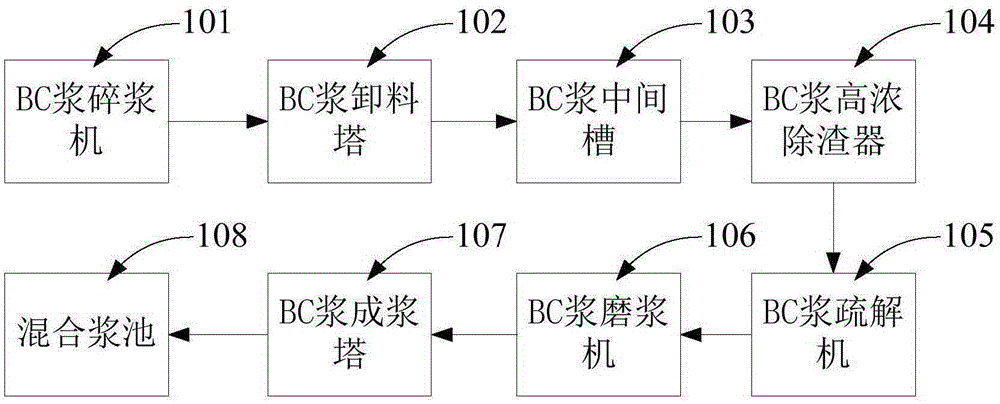

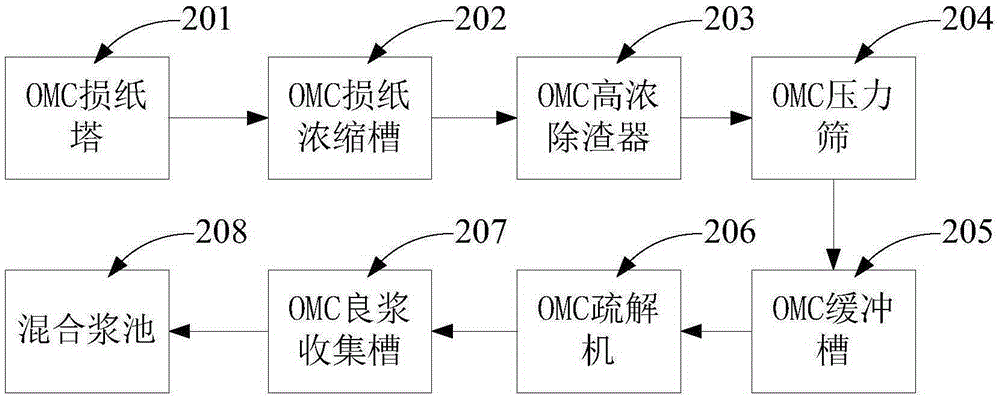

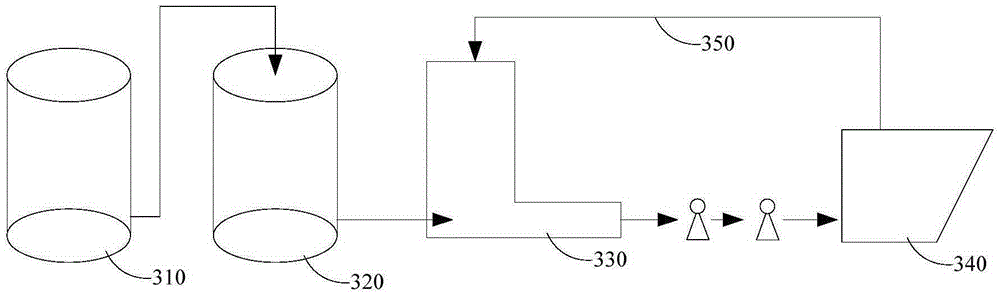

Embodiment 1

[0050] Use PAC to treat BC pulp line, the concentration of BC pulp is 4.5%, and the dosage of PAC is 0.8Kg / ton of pulp; OMC broken paper is treated with both PAC and PAE, the dosage of PAC is 0.5Kg / ton of pulp, and the dosage of PAE is 0.2Kg / ton of pulp. After treatment Then use a dispersant and a fixing agent to treat the broken paper, wherein the amount of the dispersant is 3Kg / ton of paper, the amount of the fixing agent is 0.5Kg / ton of paper, and the concentration of the broken paper is 3.5%. Use talcum powder, defoamer and PEI to treat white water. The amount of talcum powder is 3Kg / ton of paper, defoamer 0.2Kg / ton of paper, PEI 0.05Kg / ton of paper, and the concentration of white water is between 0.05-0.25. / Short fiber / mechanical pulp = 20 / 65 / 15 ratio with fresh pulp fiber, followed by fresh pulp accounting for 80%, OMC broke pulp accounting for 20% proportioning pulp, after the pulp is mixed evenly, add wet end cationic starch and Filler, dilute with white water after t...

Embodiment 2

[0055]Use PAC and PDADMAC to treat the anionic garbage of BC pulp, add PDADMAC to the BC pulper, the addition amount is 0.8Kg / ton of pulp, and add PAC0.2Kg / ton of pulp at the pump suction port of BC pulping tower. Add PA0.2Kg / ton broken paper at the outlet of the OMC broken paper tower pump, and add PEI1.5Kg / ton broken paper at the outlet of the OMC broken paper high-concentration slag remover. Then add a dispersant at the outlet of the pressure sieve, and add a fixative at the outlet of the deflaker to treat OMC broken paper. Among them, the amount of dispersant is 0.5Kg / ton of paper, and the amount of fixing agent is 5Kg / ton of paper. Treat white water with talc, defoamers, and organically modified PACs. The amount of talcum powder is 0.5Kg / ton of paper, the defoamer is 0.1Kg / ton of paper, PAC is 0.5Kg / ton of paper, the concentration of white water is between 0.05-0.25, and the fresh pulp is according to: long fiber / short fiber / mechanical pulp=20 / The ratio is 60 / 20, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge density | aaaaa | aaaaa |

| Charge density | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com