Preparation method of carbon nanotube fibers with high tensile strength

A technology of carbon nanotube fiber and high tensile strength, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., which can solve the problems of difficult application of carbon nanotube tensile strength at the macro scale, and achieve enhanced tensile strength and improved crosslinking rate, improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

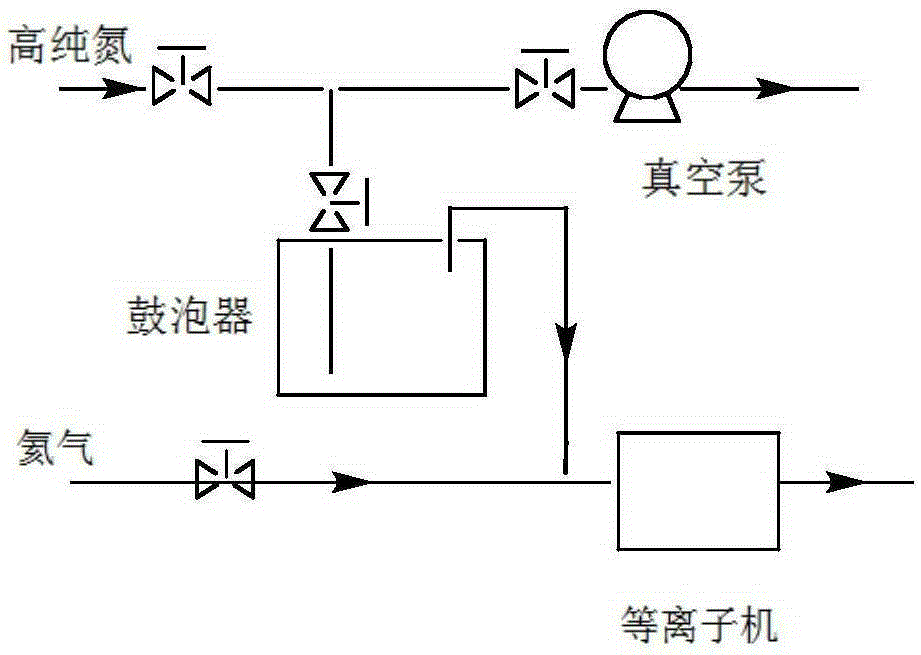

Method used

Image

Examples

Embodiment 1

[0027] Carbon nanotube growth conditions, argon atmosphere, pressure 740mmHg, temperature rise to 400°C, according to the flow rate of ethylene 0.300L / min, argon 1.000L / min for 30min; after the growth is completed, water vapor 0.030L / min, argon 2.000 L / min flow rate is cooled to room temperature.

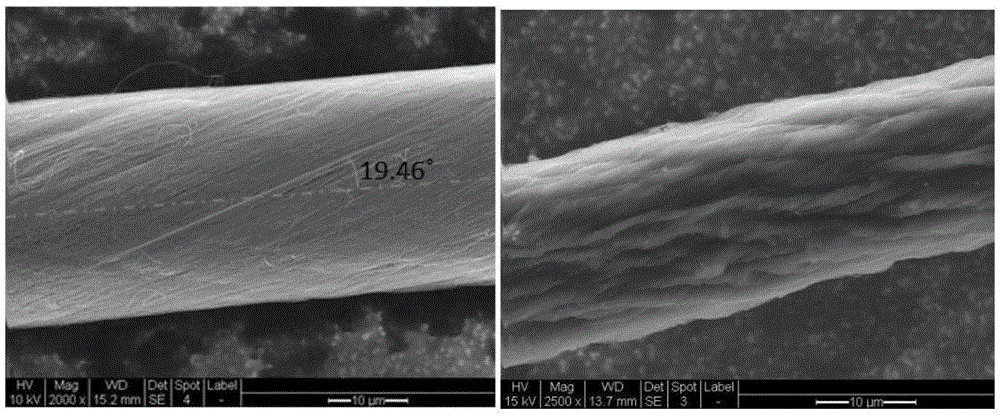

[0028] Using helium as the carrier gas, the prepared carbon nanotubes are functionalized by propylenediamine plasma, and the functionalized carbon nanotubes are prepared into functionalized carbon nanotubes by mechanical traction and twisting (using a twisting machine). fiber with a twist angle of 15 degrees.

[0029] The functionalized carbon nanotube fibers are immersed in a toluene solution containing 5% 4,4-diaminodiphenylmethane epoxy resin, the percentage is the mass fraction, and the crosslinking reaction between carbon nanotubes is carried out at room temperature for 12 hours. After the reaction, the carbon nanotube fibers were washed in a toluene solvent to remove the epox...

Embodiment 2

[0031] Carbon nanotube growth conditions, argon atmosphere, pressure is 720mmHg, temperature rises to 450°C, according to the flow rate of ethylene 0.400L / min, argon 0.800L / min, keep for 30min; then in water vapor 0.020L / min, argon 0.800L / min kept at room temperature under the condition of min.

[0032] Using nitrogen as the carrier gas, the prepared carbon nanotubes were functionalized by ethylenediamine plasma, and the functionalized carbon nanotubes were prepared into functionalized carbon nanotube fibers by mechanical traction and twisting with a twist angle of 10 degrees.

[0033] The functionalized carbon nanotube fibers are immersed in a benzene solution containing 5% triepoxide aminophenol, the percentage is the mass fraction, and the cross-linking reaction between carbon nanotubes is carried out at room temperature for 24 hours. After the reaction, the carbon nanotube fiber was washed in a benzene solution to remove the epoxy resin on the outer surface. The prepared ...

Embodiment 3

[0035] Carbon nanotube growth conditions, argon atmosphere, pressure is 700mmHg, temperature is raised to 500°C, according to the flow rate of ethylene 0.500L / min, argon 0.500L / min for 20min; then in water vapor 0.030L / min, argon 0.600L / min kept at room temperature under the condition of min.

[0036] Using nitrogen as the carrier gas, the prepared carbon nanotubes were functionalized by propylenediamine plasma, and the functionalized carbon nanotubes were prepared into functionalized carbon nanotube fibers by mechanical traction and twisting, with a twisting angle of 15 degrees.

[0037] The functionalized carbon nanotube fibers were immersed in a propylene oxide butyl ether solution containing 10% p-aminophenol epoxy resin, and a crosslinking reaction between carbon nanotubes was carried out at room temperature for 20 hours. After the reaction, the carbon nanotube fiber was washed in a benzene solution to remove the epoxy resin on the outer surface. The prepared carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com