Method for rapidly culturing aerobic granular sludge

An aerobic granular sludge, rapid technology, applied in the direction of aerobic process treatment, aerobic and anaerobic process treatment, sustainable biological treatment, etc., can solve the problems of long start-up period and shorten the start-up period of aerobic granular sludge , to achieve the effect of shortening the incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for rapidly cultivating aerobic granular sludge includes the following steps:

[0021] (1) Preparation of influent water source

[0022] The influent water source is simulated artificial wastewater, which is formulated as follows: CH 3 COONa1536mg / L, NH 4 Cl458.4mg / L, KH 2 PO 4 52.8mg / L, CaCl 2 27.8mg / L, MgSO 4 ·7H 2 O102.5mg / L, FeCl 3 0.9mg / L, H 3 BO 3 0.15mg / L, CuSO 4 ·5H 2 O0.03mg / L, KI0.18mg / L, MnCl 2 ·4H 2 O0.06mg / L, Na 2 Mo 7 O 24 ·4H 2 O0.06mg / L, ZnSO 4 ·7H 2 O0.12mg / L, CoCl 2 ·6H 2 O0.15mg / L, EDTA10mg / L, pH7~8. The simulated artificial wastewater has COD=1200mg / L, TP concentration is 12mg / L, NH 4 + -N concentration is 120mg / L, C:N:P=100:10:1 (mass ratio).

[0023] (2) Sludge inoculation

[0024] The sludge cake taken from the dewatering workshop of the sewage treatment plant is screened and washed to remove impurities such as leaves and sand, and then exposed to simulated artificial wastewater for 1-2 days. A certain amount of the sludge after the exposure is a...

Embodiment 2

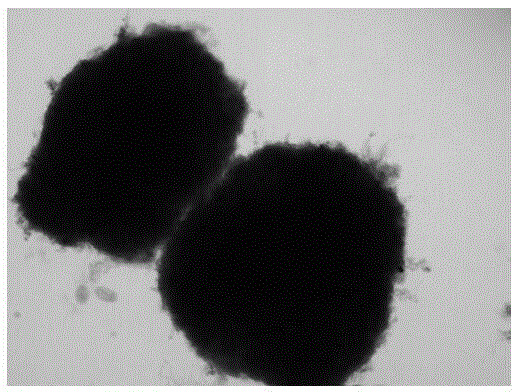

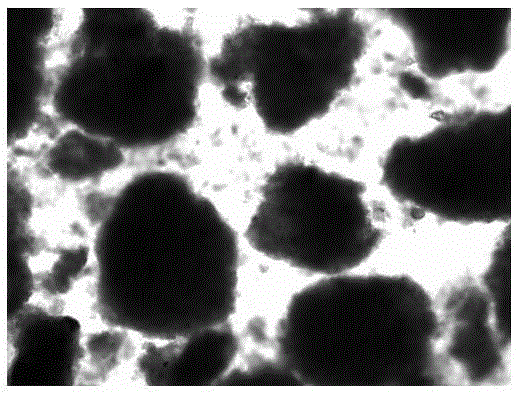

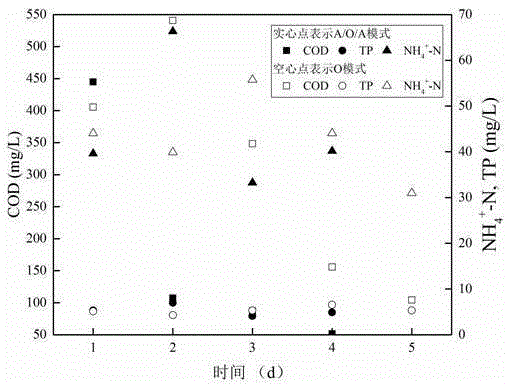

[0029] Take the mud cake from the dehydration workshop of a sewage treatment plant in Wuhan, and use the method in Example 1, respectively to operate and control in anaerobic / aerobic / anoxic (A / O / A) and one-stage aeration (O) modes. At room temperature, the aerobic granular sludge can be obtained in an SBR reactor operating in anaerobic / aerobic / anoxic mode for 4 days. The electron microscope picture (4×10 times) is as figure 1 As shown; the aerobic granular sludge can be obtained in 5 days in the SBR reactor operating in the one-stage aeration mode, and the electron microscope picture (4×10 times) is as figure 2 Shown. COD, TP, NH in SBR reactor operating in two modes 4 + -N effluent concentration changes such as image 3 Shown.

[0030] Figure 1-2 It shows that the aerobic granular sludge obtained by the present invention has a relatively regular shape, a typical spherical or ellipsoidal shape, a relatively neat edge and a compact structure. The aerobic granular sludge obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com