Bridge type chain bucket car unloader

A technology of bucket unloader and bridge chain, which is applied in the field of bridge chain bucket unloader, can solve the problems of lowering production level, affecting work progress, reducing work efficiency, etc., so as to improve production level, liberate labor productivity, and achieve reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

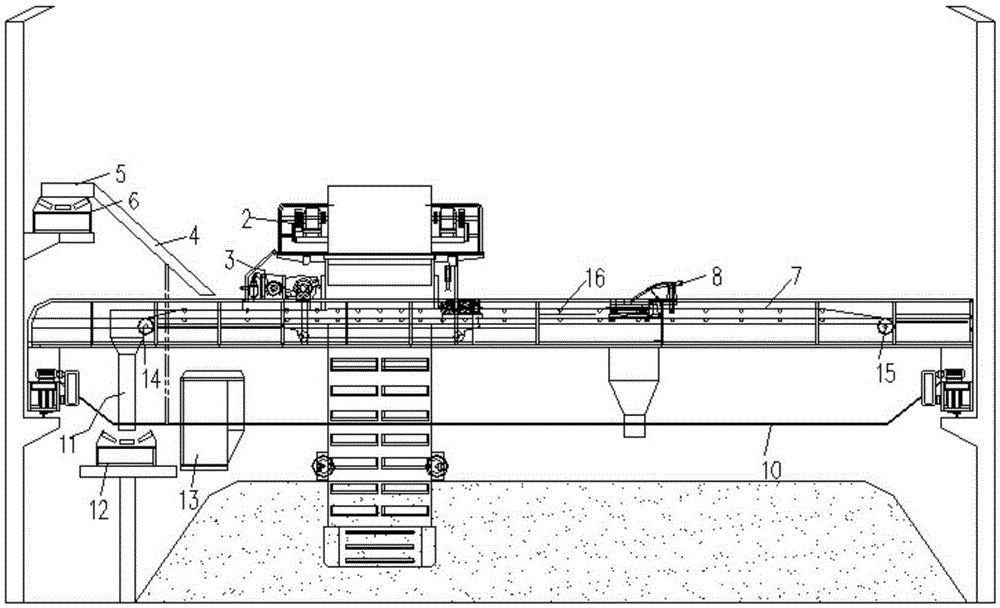

[0014] Such as Figure 1-2 As shown, the present invention provides a bridge-type chain bucket unloading coke and sand unloading machine, which includes a hopper box 1, an equipment belt conveyor 7 and a metal bracket 10, and the two sides of the hopper box 1 are provided with a tipping mechanism 2, and the tipping mechanism 2 The bottom of the lifting mechanism 3 is provided with a lifting mechanism 3, one side of the lifting mechanism 3 is provided with a material conveying frame 4, the top of the material conveying frame 4 is provided with a mobile throwing trolley 5, and the bottom of the mobile throwing trolley 5 is provided with a first main belt machine 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com