Method for processing tea table

A processing method and tea table technology, which is applied in the manufacture of tools, tables, household utensils, etc., can solve the problems of large difference in chord shrinkage between sapwood and heartwood, African rosewood is not easy to dry, and cost increases, so as to reduce structural defects Defects, reduced sculpture time, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

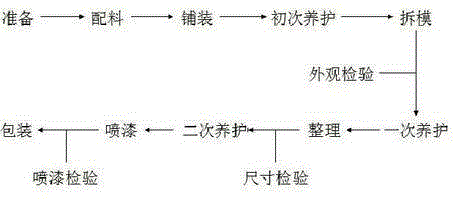

[0021] Such as figure 1 Shown, the processing method of tea table of the present invention comprises the processing method of tea table parts, and concrete steps are as follows:

[0022] (1) Paving: Pave the fabric for making tea table parts into the mold, and then pave the middle material; then add steel sheets to the middle material, and finally close the mold;

[0023] (2) Initial maintenance to make the tea table parts initially set;

[0024] (3) Demolding: separate the tea table parts from the mould;

[0025] (4) The first maintenance, so that all parts of the tea table components are basically dry;

[0026] (5) Trimming: cutting off the burrs and repairing;

[0027] (6) The second maintenance, so that all parts of the tea table components are completely dry;

[0028] (7) Spray paint: Spray paint the tea table parts to achieve the expected surface effect.

Embodiment 2

[0030] Such as figure 1 Shown, the processing method of tea table of the present invention comprises the processing method of tea table parts, and concrete steps are as follows:

[0031] (1) Paving: pave the fabric for making tea table parts into the mold, and then pave the middle material; then add steel sheets to the middle material, and finally close the mold; the ingredients of the fabric and the middle material include silicon powder, Sulphoaluminate cement, sawdust and alkali-resistant glass fiber mesh;

[0032] (2) The initial maintenance, so that the tea table components are initially set, and the initial maintenance time is 12 hours;

[0033] (3) Demolding: separate the tea table parts from the mould;

[0034] (4) Appearance and size inspection: inspect the appearance quality and size of tea table components;

[0035] (5) The first maintenance, so that all parts of the tea table components are basically dry;

[0036] (6) Dimensional inspection: check the dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com