Production process of paste-fragrant fresh soybean sauce

A production process and technology of soy sauce, applied in the direction of food science, etc., can solve the problems of thick taste and lack of soy sauce, and achieve the effect of delicate taste, rich taste and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

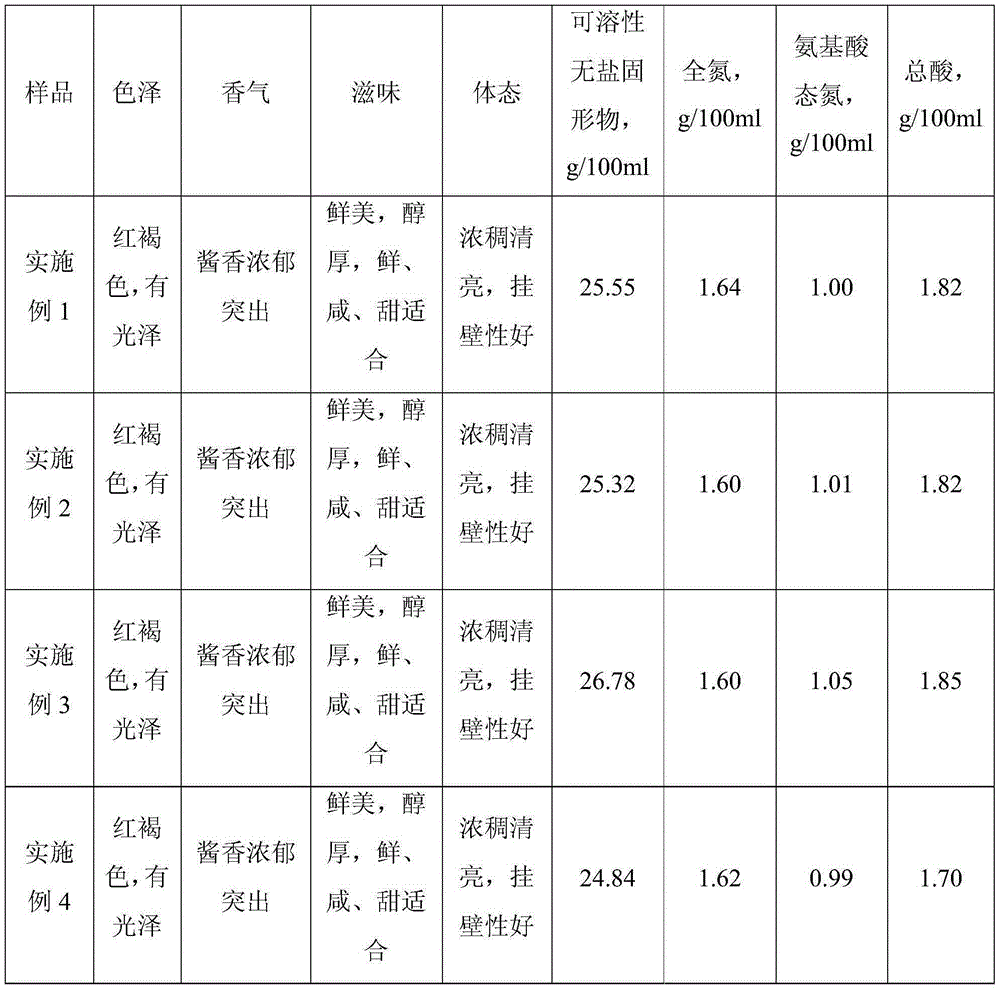

Examples

preparation example Construction

[0024] The preparation method of the present invention specifically comprises the following steps:

[0025] 1) Mix defatted soybeans and wheat at a weight ratio of 1:1 to 7:3, add water to moisten the defatted soybeans in a cooking pot, and then steam them. -50% wheat is roasted at a high temperature of 300-330°C, cooled to about 40°C, milled and mixed with cooked 50-70% defatted soybeans;

[0026] 2) Then inoculate (aspergillus oryzae dosage 0.04-0.06%), koji making (add mixed brine accounting for 1-2.4 times the total amount of wheat and defatted soybeans for fermentation, add yeast to continue fermentation within 30 days of fermentation, and when the fermentation period expires 1 - After 12 months, it matures into soybean paste;

[0027] 3) Soybean paste is extracted by physical pressing to conventional soy sauce (soybean paste content is 8-13%). %) is mixed according to the weight percentage ratio of 1%-30% (preferably range 1%-10%), sieved to remove grain impurities suc...

Embodiment 1

[0031] Ingredients (% by weight): defatted soybean 70%, wheat 30%.

[0032] A preparation method of soy sauce with soy sauce, comprising the following process steps:

[0033] 1) Add water to the defatted soybeans in the cooking pot to moisten them, then steam them, release the pressure after steaming, cool down, and discharge; roast the wheat at high temperature, cool down, grind, mix with cooked defatted soybeans, and then inoculate , making koji, mixing salt water, entering the fermentation tank to start fermentation, adding yeast to continue fermentation within 30 days of fermentation, and ripening into soybean paste after 6 months of fermentation.

[0034] 2) Soybean paste is extracted from conventional soy sauce by physical pressing, and part of the soy paste is physically ground to form finely ground soy sauce. The finely ground soy sauce is mixed with conventional soy sauce at a ratio of 1:10, and the wheat husk is removed through a 60-mesh filter screen. Particle impu...

Embodiment 2

[0038] Ingredients (% by weight): defatted soybean 60%, wheat 40%

[0039] A preparation method of soy sauce with soy sauce, comprising the following process steps:

[0040] 1) Add water to the defatted soybeans in the cooking pot to moisten them, then steam them, release the pressure after steaming, cool down, and discharge; roast the wheat at high temperature, cool down, grind, mix with cooked defatted soybeans, and then inoculate , making koji, mixing salt water, entering the fermentation tank to start fermentation, adding yeast to continue fermentation within 30 days of fermentation, and ripening into soybean paste after 3 months of fermentation.

[0041] 2) Soybean paste is extracted by physical pressing to extract conventional soy sauce, and part of the soy paste is physically ground to form finely ground soy sauce. The finely ground soy sauce is mixed with conventional soy sauce at a ratio of 1:9, and the wheat husk is removed through a 60-mesh filter screen. Particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com