Permanent magnet speed adjuster with fixed magnetic gap

A permanent magnet governor and fixed magnet technology, applied in the direction of permanent magnet clutches/brakes, etc., can solve the problem of not being able to rotate to drive the load, etc., to save installation space, reduce heat generation, and reduce material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

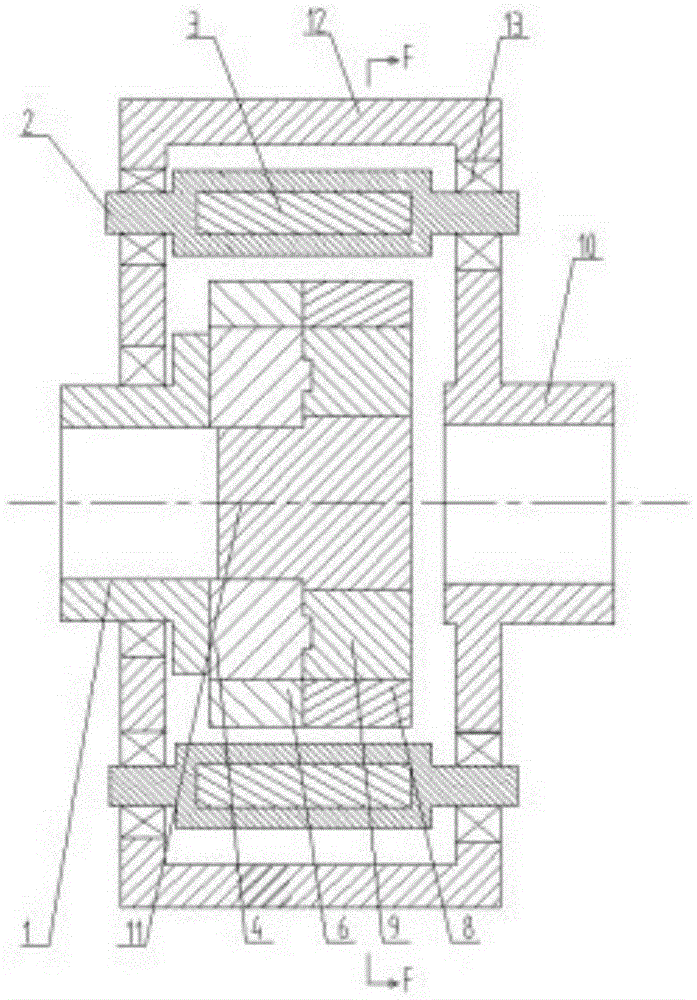

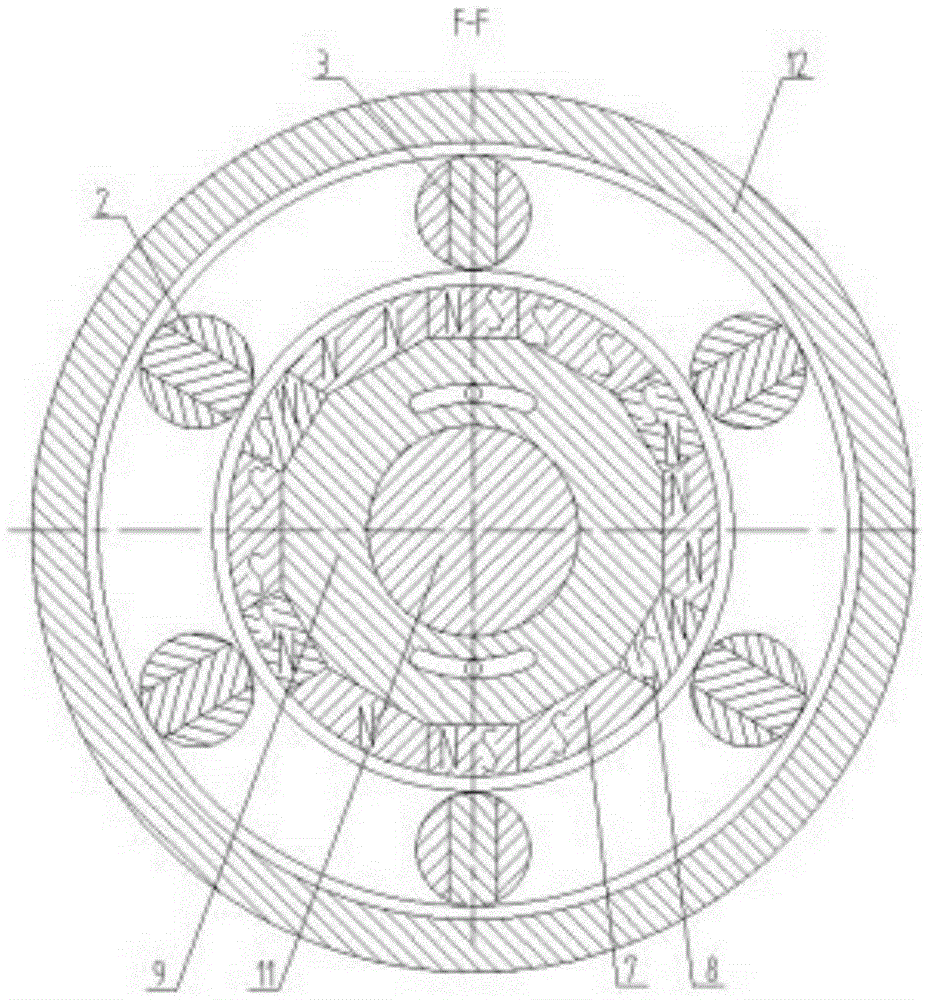

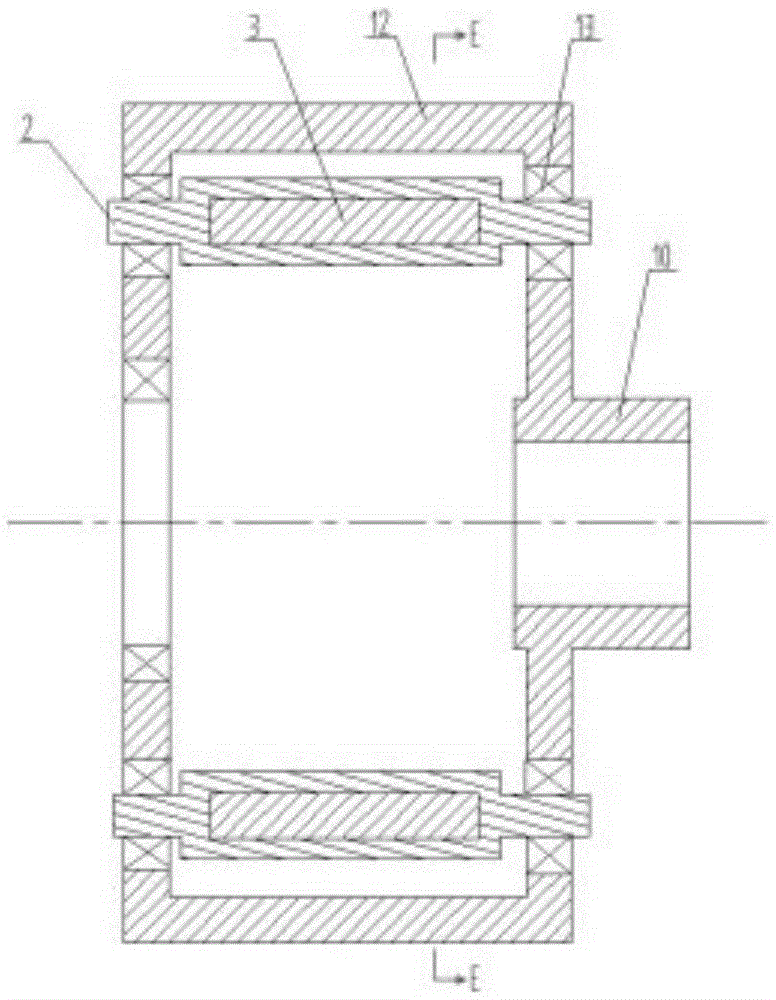

[0025] A permanent magnet governor with a fixed magnetic gap, including a first inner magnetic rotor 4 and a second inner magnetic rotor 9 through which a driving shaft 1 passes concentrically, an outer magnetic rotor frame 12 connected to a driven shaft 10, and an outer magnetic rotor 2. The outer magnetic rotor 2 is mounted on the outer magnetic rotor frame 12 through bearings 13 assembled at both ends, and the bearings 13 can be one-way bearings or two-way bearings. The outer magnetic rotor 2 has at least two outer permanent magnets 3 uniformly distributed along its inner circumferential surface, and the first inner magnetic rotor 4 and the second inner magnetic rotor 9 are both circumferentially distributed along their respective outer circumferential surfaces. At least two first inner permanent magnets 6 and second inner permanent magnets 8 are evenly distributed, and the magnetic poles of each inner permanent magnet are arranged along the circumferential direction, and th...

Embodiment 2

[0027] The invention relates to a permanent magnet governor with a fixed magnetic gap. The magnetic poles of each inner permanent magnet are arranged radially, and the adjacent side magnetic poles of two adjacent inner permanent magnets on the same inner magnetic rotor are magnetically different. All the other parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com