Harmonic gear speed reducer

A technology of harmonic gears and reducers, which is applied in the direction of belts/chains/gears, mechanical equipment, transmissions, etc., to achieve the effect of slowing down the inclination angle and increasing the meshing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

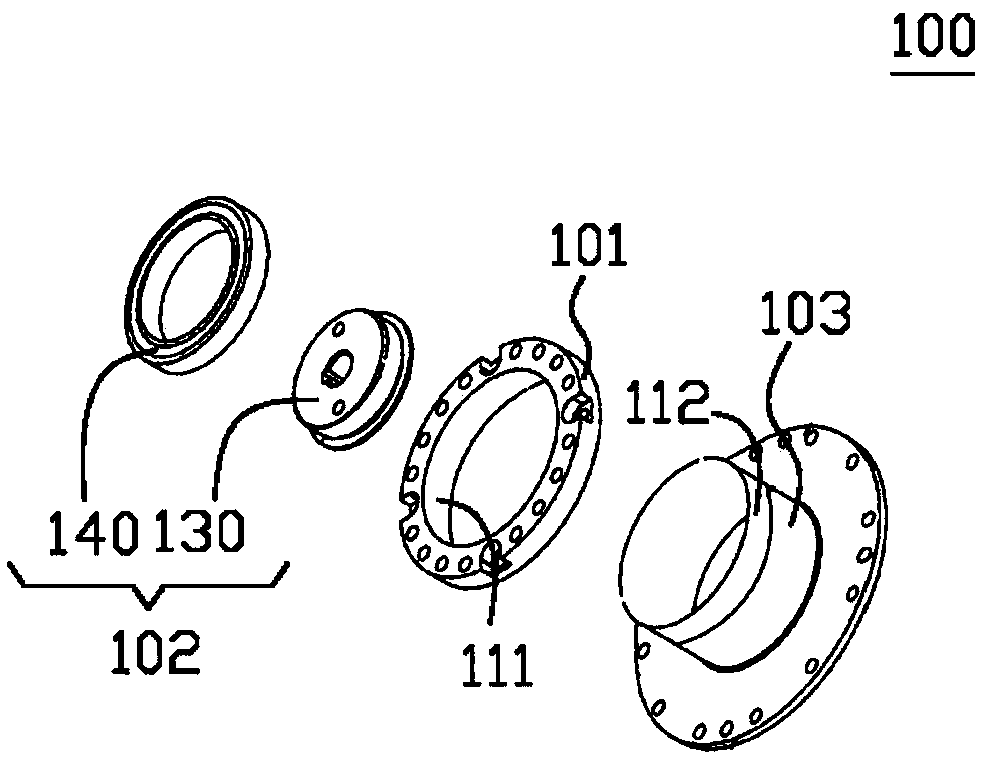

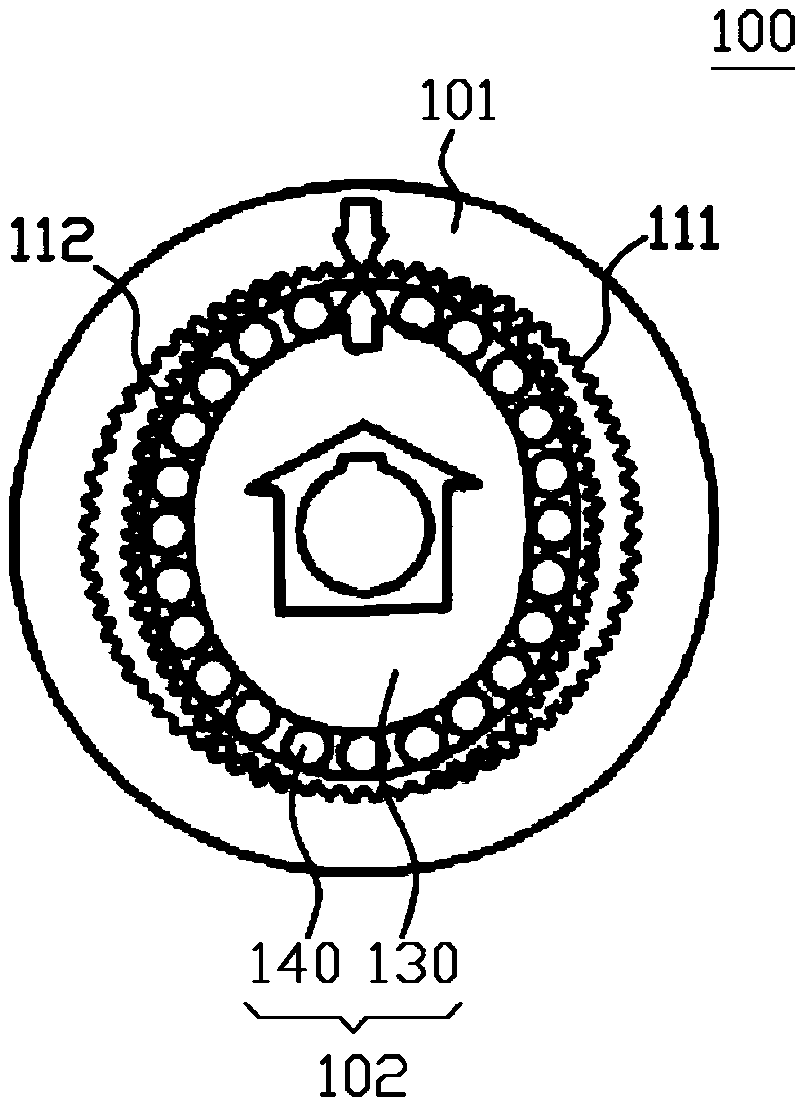

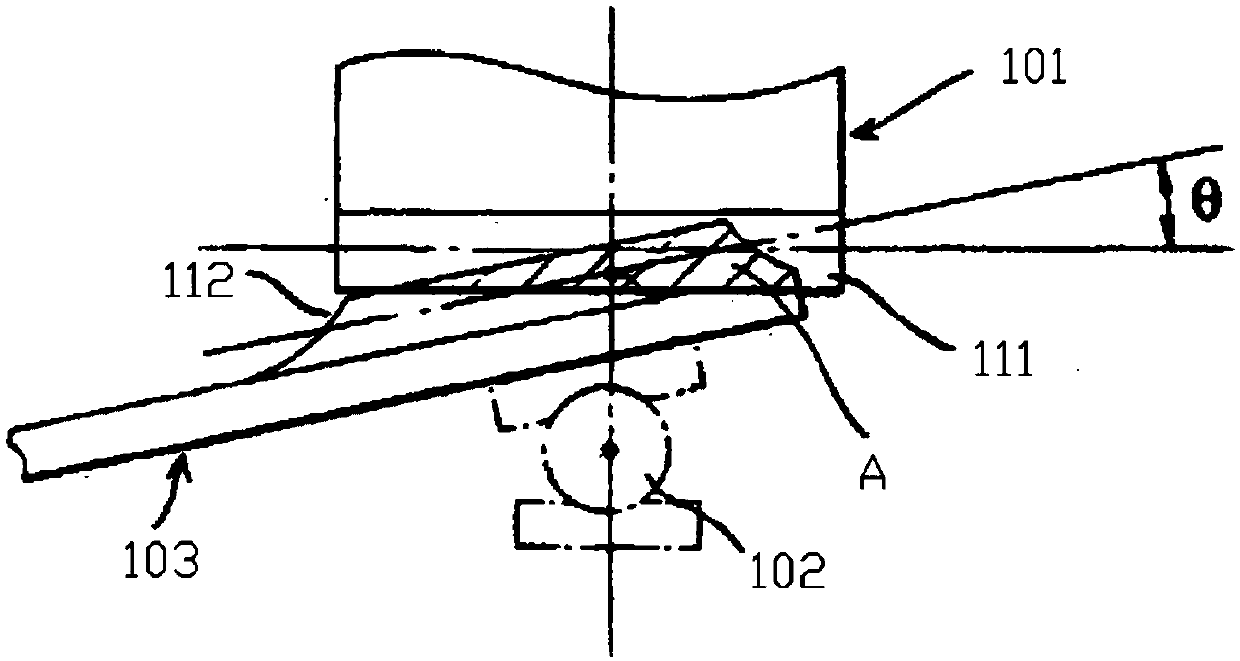

[0056]In order to solve the aforementioned problems, according to an embodiment of the present invention, a circular but non-continuous thin groove is cut on the body of the flexspline cylinder. When the wave generator is placed in the inner hole of the flexspline cylinder, the flexspline cylinder The body is constrained by the outer contour of the wave generator, so that the cylinder body is in the shape of a flared bell mouth at the long axis of the wave generator. At this time, due to the presence of ring-row fine grooves in the flexspline body, a discontinuous elastic deformation occurs at the groove position of the flexspline body, which slows down the outward expansion inclination angle of the flexspline body. , thus achieving the effect of increasing the meshing area of the rigid-flex gear teeth. Hereinafter, the present invention will be described in detail with reference to the accompanying drawings, wherein the same reference numerals will be used to identify the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com