Portable charger transformer automatic production linkage mechanism and its use method

A portable charger and linkage mechanism technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of low charging rate, affecting the drive of transformers, wasting manpower and material resources, reducing personnel participation, Improve equipment efficiency and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this embodiment, the laser process and the automatic soldering process connected before and after the portable transformer are used as an example to further describe the present invention. The first device 5 is a laser device 5.

[0026] In this embodiment, for the convenience of description, such as Figure 5 The figure shown is for reference. Place the portable transformer with its pins facing up. The surface where the pin 61 is located is defined as the upper part of the transformer, the part below the surface where the pin 61 is located is defined as the transformer body, and the side where the secondary winding of the upper transformer is located is defined as the transformer The upper left end 62, the side where the upper primary winding of the transformer is located, is defined as the upper right end 63 of the transformer.

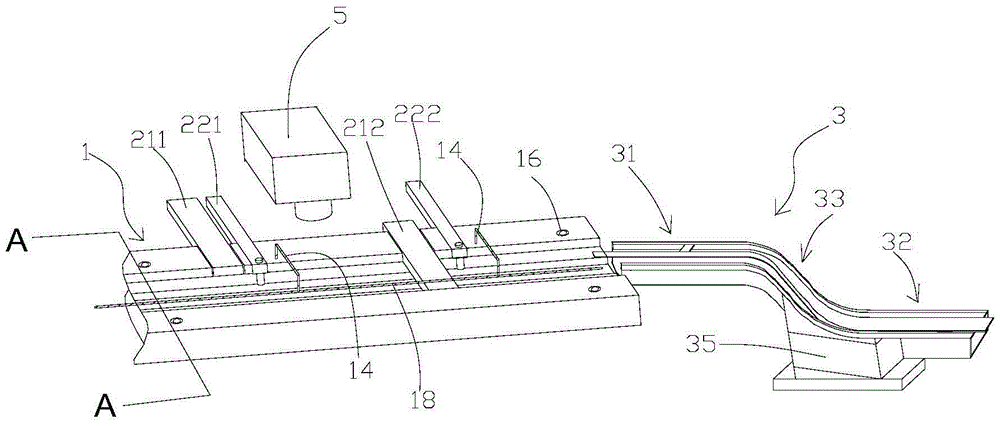

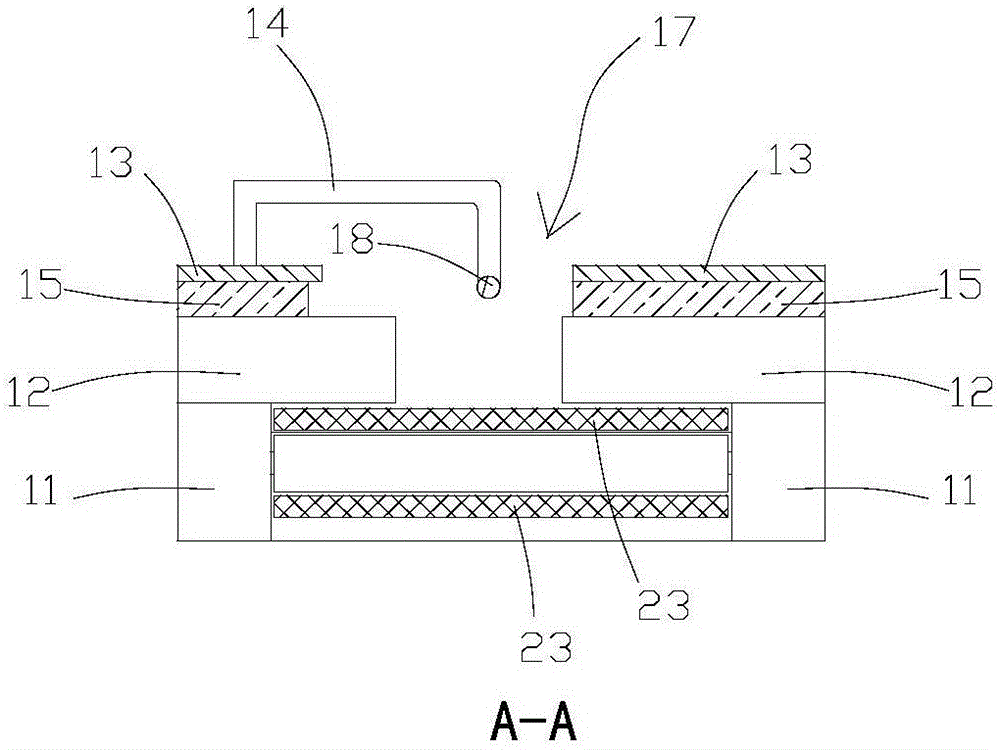

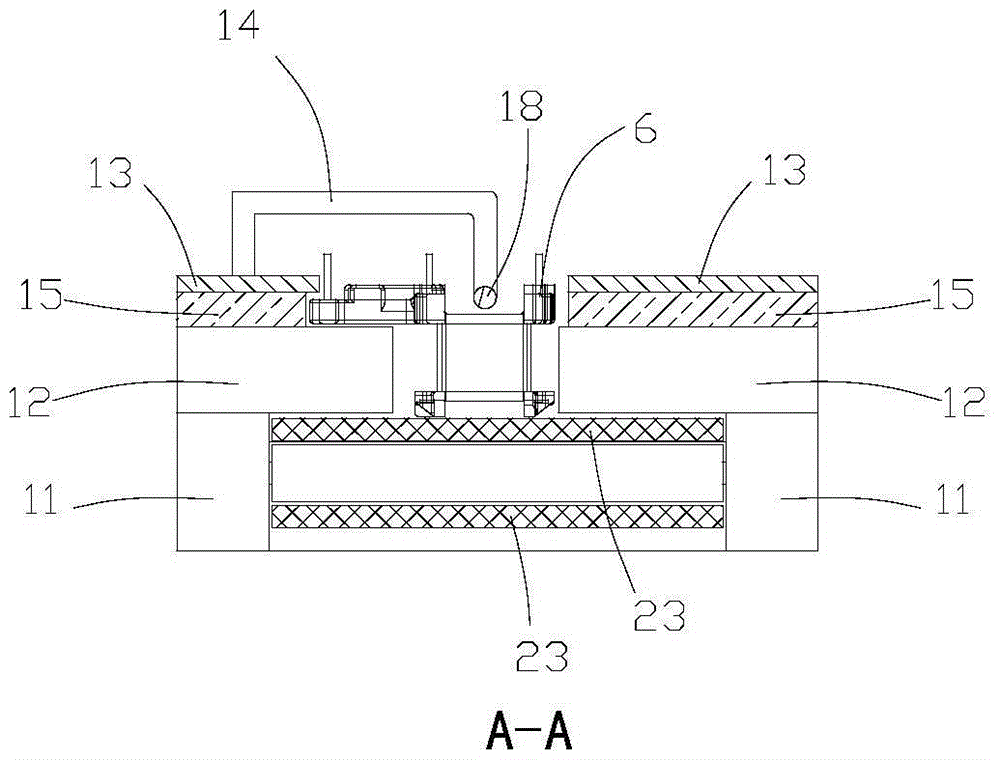

[0027] Such as figure 1 , figure 2 As shown, a portable charger transformer automatic production linkage mechanism is provided with a conveyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com