Surface-enhanced Raman scattering substrate with pin holes in its surface and preparation method

A surface-enhanced Raman and pinhole technology, which is applied in Raman scattering, material excitation analysis, etc., can solve problems such as weak adsorption capacity, poor chemical stability of metal nanostructures, and limit the development of surface-enhanced Raman technology. Application range, good surface to enhance Raman activity, and the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Clean the silicon substrate or glass substrate sequentially with acetone, alcohol and deionized water and dry them;

[0020] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0021] 3. At room temperature, using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to a vacuum degree of 3×10 -5 Pa;

[0022] 4. Adjust the incident angle of the electron beam to 85°, and make the sample stage static, and grow a silver nanorod array thin film with a nanorod length of 700nm obliquely on the substrate of the sample stage;

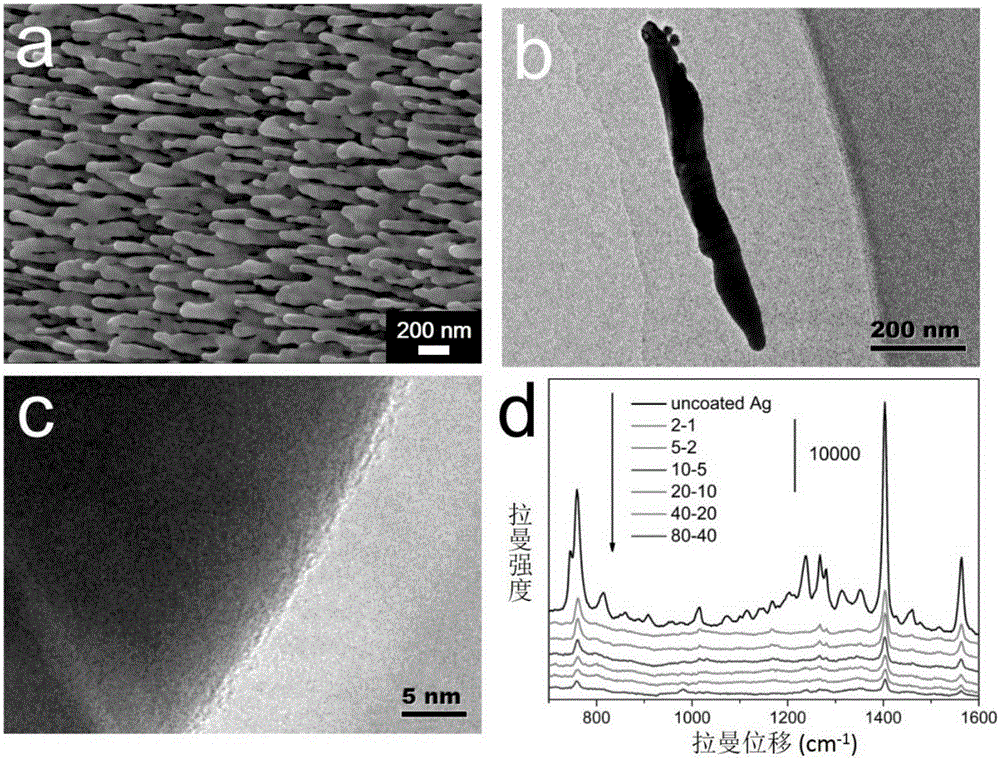

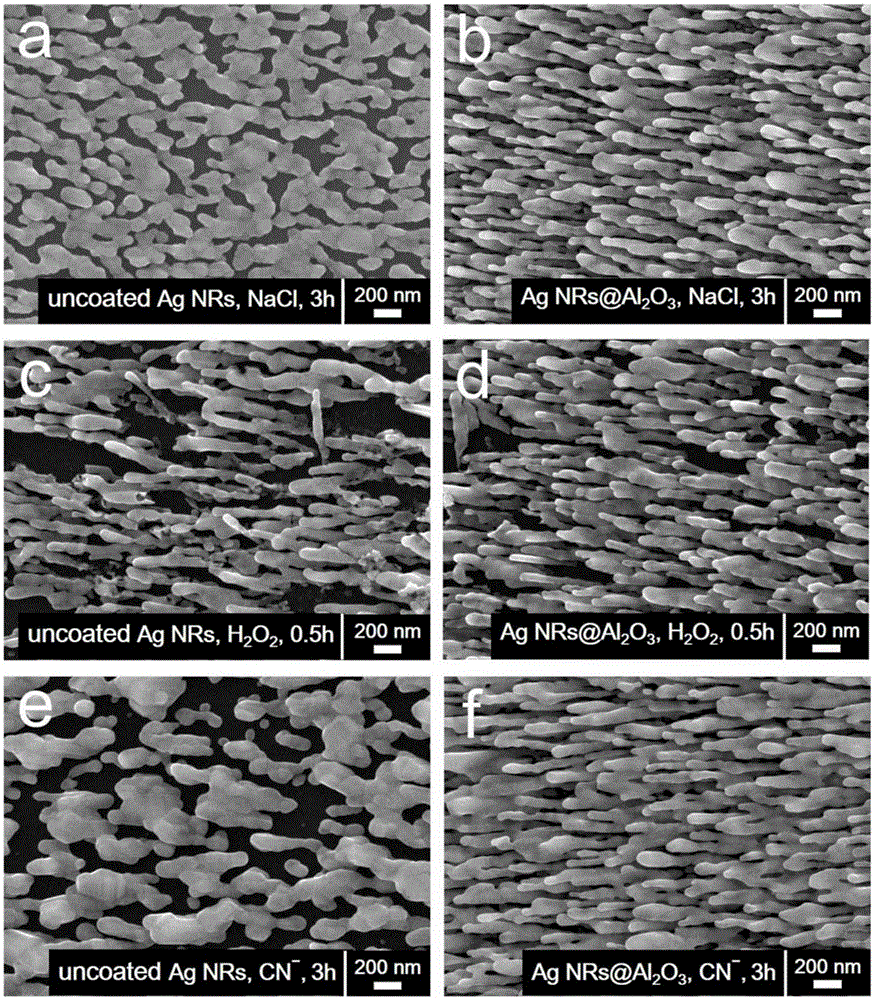

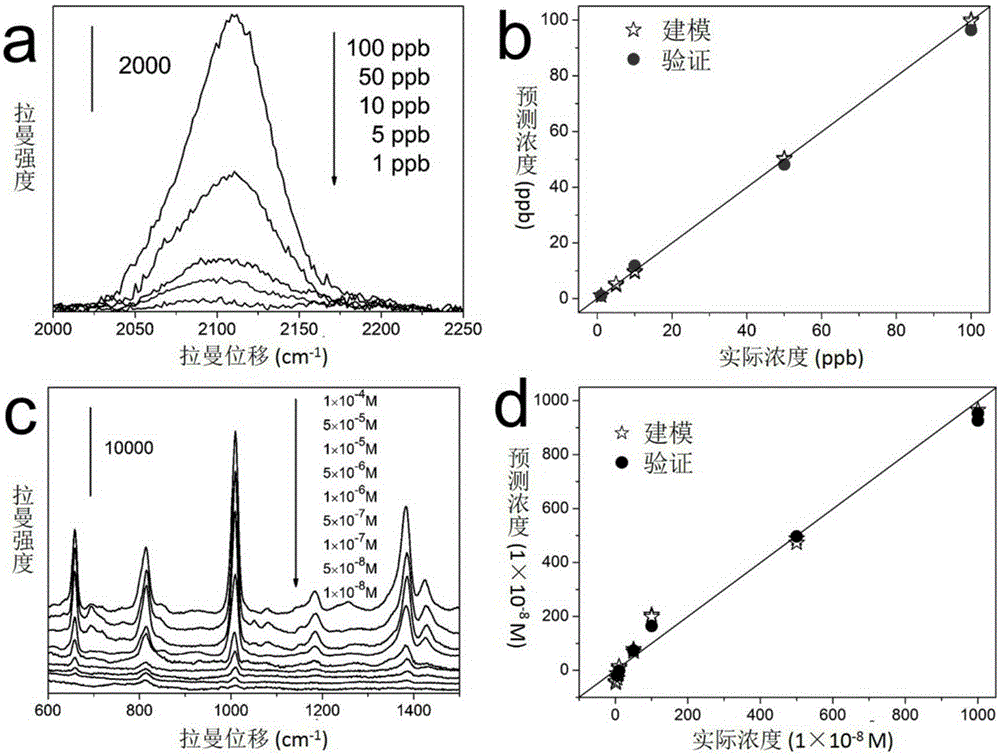

[0023] 5. By the low-temperature atomic layer deposition method, heat the chamber to 70°C, control the flow rate of trimethylaluminum and water to 20 sccm, and control the pinhole ratio of the aluminum oxide film by adjusting the time of trimethylaluminum and water, The penetration time of trimethylaluminum is 2ms, 5ms, 10ms, 20ms, 40ms, 80ms resp...

Embodiment 2

[0028] 1. Clean the silicon substrate or glass substrate sequentially with acetone, alcohol and deionized water and dry them;

[0029] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0030] 3. At room temperature, using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to a vacuum degree of 5×10 -5 Pa;

[0031] 4. Adjust the incident angle of the electron beam to 86°, and make the sample stage rotate at a rate of 6rpm, and grow a silver nanorod array film with a nanorod length of 600nm obliquely on the substrate of the sample stage;

[0032] 5. Through the low-temperature atomic layer deposition method, heat the chamber to 60°C, control the flow rate of trimethylaluminum and water to 20sccm, and the feeding time is 10ms and 5ms respectively, and uniformly deposit a layer on the surface of the silver nanorod array film with Alumina film with pinholes, to obtain a silv...

Embodiment 3

[0037] 1. Clean the silicon wafer substrate or glass substrate sequentially with acetone, alcohol, and deionized water, and then dry it;

[0038] 2. Fix the pretreated substrate on the sample stage of the electron beam evaporation coating machine;

[0039] 3. At room temperature, use metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 8×10 -5 Pa high vacuum;

[0040] 4. Adjust the incident angle of the electron beam to 88°, and make the sample stage rotate at a rate of 10rpm, and grow a silver nanocylindrical straight rod array film with a nanorod length of 400nm on the substrate of the sample stage;

[0041] 5. Through the low-temperature atomic layer deposition method, heat the chamber to 50°C, control the flow rate of trimethylaluminum and water to 20sccm, and the feeding time is 80ms and 40ms respectively, and uniformly deposit a layer on the surface of the silver nanocylindrical straight rod array film Alumina fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com