Filling reinforcement method for managing underground mined area of open-pit mine

A technology for gobs and open-pit mines, which is applied to fillings, mining equipment, earthwork drilling and mining, etc. It can solve problems such as low compressive strength, long construction period, and surface subsidence, so as to save costs and improve construction efficiency , the effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

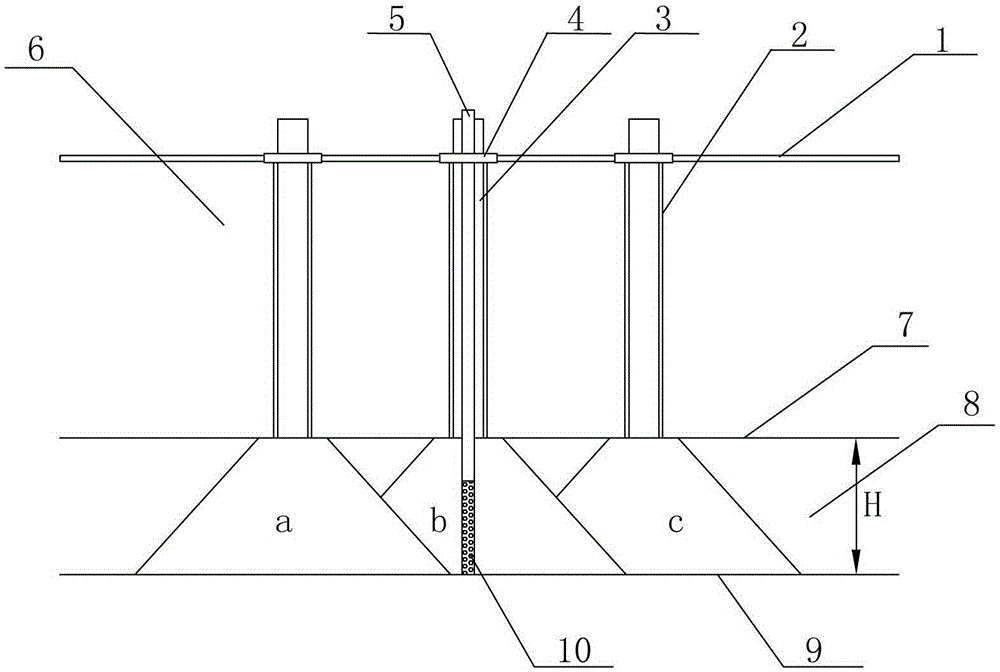

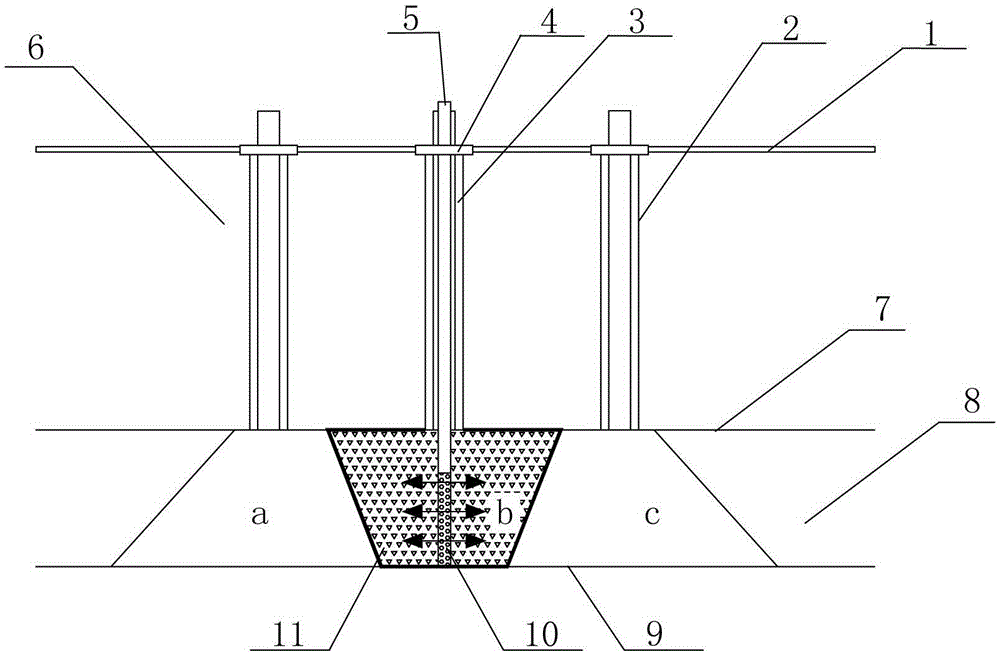

[0023] like figure 1 and figure 2 As shown in the figure, a filling and reinforcement method for treating an underground goaf in an open-pit mine of the present invention is characterized in that it comprises the following steps:

[0024] 1) Determine the arrangement of the backfill boreholes in the underground goaf and drill the backfill boreholes. The backfill borehole 2 penetrates the rock layer 6 to the roof 7 of the goaf. 8. When the width of the goaf is less than or equal to 5m and the height H is within 2m to 2.5m, the backfill hole 2 shall adopt a single row of backfill holes along the direction of the gob; when the height H of the gob 8 is greater than 2.5m , when the width is greater than 5m, the backfill drill hole 2 adopts double or multi-row backfill drill holes along the direction of the goaf.

[0025] 2) A feeding pipe 3 of a tray 4 is inserted into each filling hole 2, and the lower nozzle of the feeding pipe 3 extends into the roof 7 of the underground goa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uniaxial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com