An inner diaphragm type concrete filled steel pipe transfer node structure and its construction method

A technology of steel pipe concrete and transfer nodes, which is applied in the direction of building structure and construction, and can solve the problems of reduced use space of transfer floor buildings, low bearing capacity of reinforced concrete components, and poor confinement effect of core concrete, so as to ensure construction quality, Good lateral force resistance and fewer force transmission units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

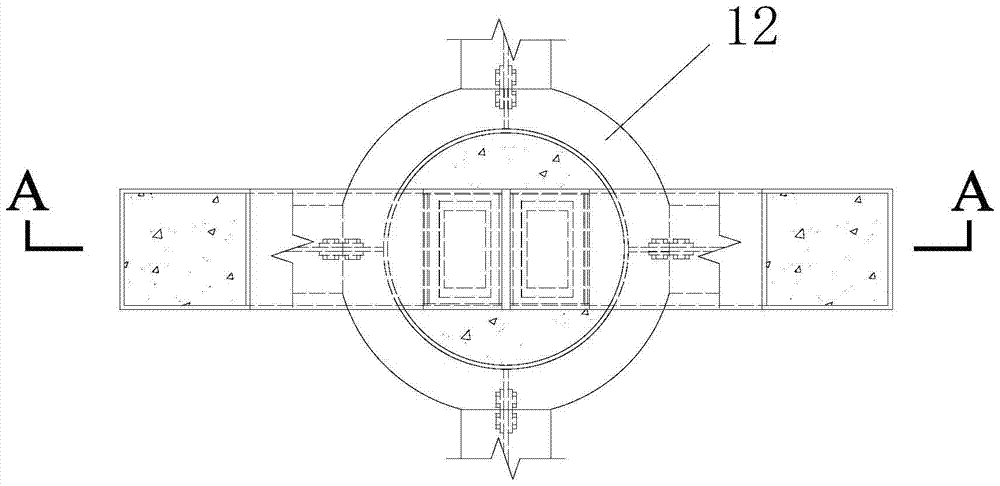

[0066] An inner diaphragm type concrete-filled steel tube transfer node structure, including a pillar 1, a slanting column 2, and a receiving frame 3 for connecting the slanting column to the pillar. The slanting column has a section, and the section includes a cross section 7. The receiving frame Fixedly arranged inside the pillar and located at the top of the pillar, the receiving frame includes a lower inner partition 4 and a vertical inner rib 5, and the vertical inner rib is fixed on the lower inner partition, wherein the shape of the vertical inner rib is consistent with the inclined The shape of the cross-section of the column is corresponding, and the oblique column is fixed to the vertical inner floor through the cross-section.

[0067] Preferably, the receiving frame is also provided with a protruding vertical inner rib 6 protruding from the outside of the pillar, and the section also includes a vertical section 8, the protruding vertical inner rib is fixed on the low...

Embodiment 2

[0077] The difference between this embodiment and the first embodiment is that the slanted columns are two circular slanted columns 21, the cross section of the slanted columns is an arc-shaped cross section, and the cross section of the two slanted columns forms an arc section , the vertical section of the inclined column is an arc-shaped vertical section, the vertical inner ribs enclose an arc joint 161, the protruding vertical inner ribs are arranged in the middle of the arc joint, and the arc cross-sections are fixedly connected On the arc joint, the arc vertical sections of the two oblique columns are respectively fixedly connected to the two sides of the protruding vertical inner ribs. The vertical inner ribs can be two arc-shaped vertical inner ribs 51, and the openings of the two arc-shaped vertical inner ribs are respectively fixedly connected with the protruding vertical inner ribs.

Embodiment 3

[0079] A construction method for an inner diaphragm type concrete-filled steel pipe conversion node, which cuts the nozzle of the inclined column to be connected, and cuts out a cross section and a vertical section respectively;

[0080] Make the vertical inner ribs into the same shape as the cross-section of the inclined column, then set the protruding vertical inner ribs in the middle of the shape surrounded by the vertical inner ribs, and place the bottom of the protruding vertical inner ribs and the vertical inner ribs The bottom of the plate is welded to the lower inner partition, and the outer edge of the lower inner partition is welded to the inner wall surface of the pillar, and the lower inner partition has a first pouring hole, and the upper part of the protruding vertical inner rib protrudes from the pillar outside;

[0081] Butt the pillar with the lower CFST column, and pour concrete to the node area;

[0082] Hoist the inclined column in place and weld the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com