Special-shaped section support pile closed type enclosure system and construction method thereof

A technology of special-shaped section and enclosure system, which is used in excavation, infrastructure engineering, construction, etc., can solve the problems of low flexural rigidity and flexural bearing capacity, and high cost of closed water-stop curtain engineering, so as to improve the cross-section resistance. The effect of bending bearing capacity, environmental protection and project cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

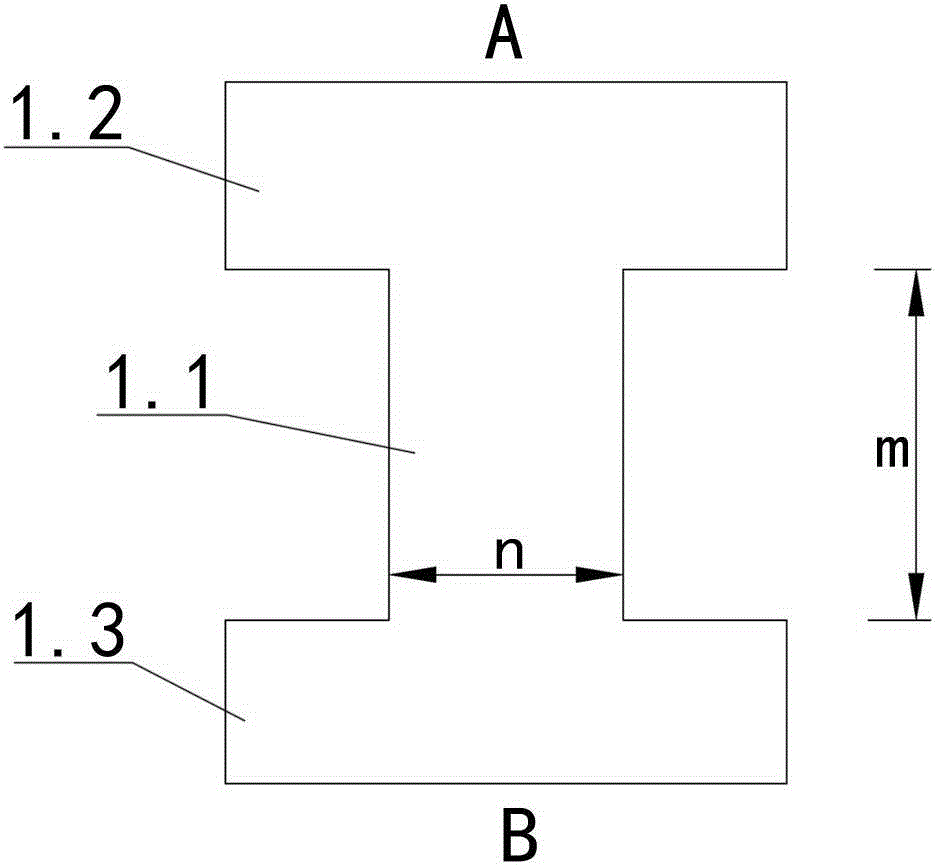

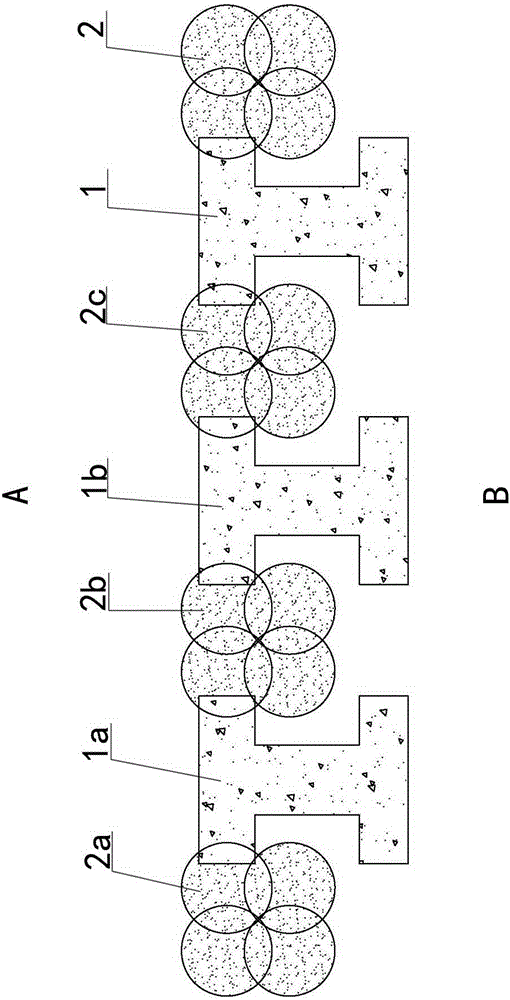

[0035] Embodiment one sees Figure 1-2 As shown, this kind of closed enclosure system of special-shaped cross-section support piles is arranged along the periphery of the foundation pit. The side A in the figure is the side facing the pit, and the side B is the side facing the soil. This closed enclosure system of special-shaped cross-section support piles includes a row of special-shaped cross-section support piles 1 and cement-soil piles 2 alternately spaced and occluded into a closed type. The special-shaped cross-section support piles 1 are reinforced concrete pouring piles, which bear The water and soil pressure is composed of the web 1.1 perpendicular to the side wall of the foundation pit, the occlusal flange 1.2 on the side facing the pit parallel to the side wall of the foundation pit, and the flange 1.3 on the side facing the soil parallel to the side wall of the foundation pit.

[0036] The height m of the cross section of the web 1.1 along the direction perpendicul...

Embodiment 2

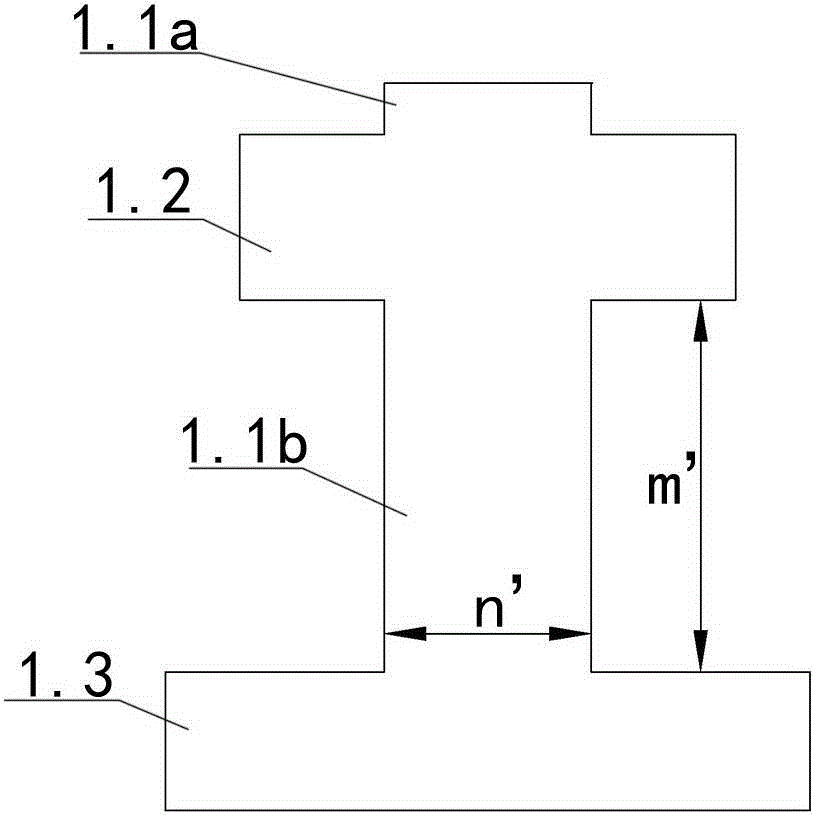

[0040]Embodiment two see Figure 3-4 As shown, the difference from Example 1 is that the web 1.1 is divided into the front abdomen 1.1a protruding from the outer edge of the pit-side occlusal flange 1.2 and the front abdomen 1.1a located at the pit-side occlusal flange 1.2 and the pit-face The rear web 1.1b between the soil side flanges 1.3, the width of the pit-facing side occlusal flange 1.2 along the direction parallel to the foundation pit side wall is smaller than the width of the soil-facing side reinforcing flange 1.3 along the direction parallel to the foundation pit side wall, so that the front web Plate 1.1a, pit-facing side occlusal flange 1.2, rear web 1.1b and soil-facing side flange 1.3 form a special-shaped cross-section support pile with a soil-shaped cross section. The height m' of the cross section of the rear web 1.1b along the direction perpendicular to the side wall of the foundation pit is greater than the width n' of the cross section of the rear web 1.1...

Embodiment 3

[0042] Embodiment three see Figure 5-6 As shown, different from Embodiment 1 and Embodiment 2, the width of the engaging flange 1.2 on the side facing the pit along the direction parallel to the side wall of the foundation pit is greater than the width of the strengthening flange 1.3 on the side facing the soil along the direction parallel to the side wall of the foundation pit, so that The front web 1.1a, the occlusal flange 1.2 on the pit-facing side, the rear web 1.1b and the soil-facing side flange 1.3 form a special-shaped cross-section support pile with a Z-shaped cross section.

[0043] The construction method of the special-shaped cross-section support pile closed enclosure system of the above embodiment, the construction steps are as follows:

[0044] Step 1. According to the hydrogeological conditions of the proposed site and the excavation depth of the foundation pit, the calculation and analysis of the closed enclosure system is carried out, the form of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com