Czochralski method single-crystal silicon growth flow field control technology

A control technology, a technology of single crystal silicon, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as failure to achieve predetermined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

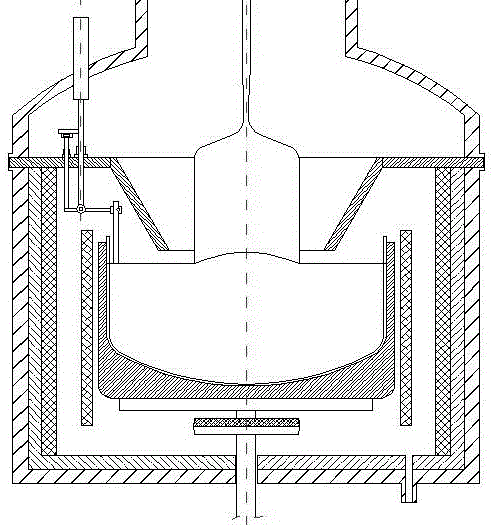

Image

Examples

Embodiment 1

[0041] To grow single crystal silicon with a diameter of 154mm, a crucible with a diameter of 308mm was used, the rotation speed of the crystal was 10rpm, the rotation speed of the crucible was 5rpm, and the rotation direction of the crystal was opposite to that of the crucible. The double helix structure bottom heater made of hard carbon material, the size of the bottom heater is 154mm, the central resistivity is high, and the resistivity decreases from the center to the outside, and the resistance change is controlled by controlling the change of the width of the heater, which decreases every 10cm 5%. During crystal growth, the temperature at the center of the bottom of the crucible is controlled to be 5°C higher than that of the surrounding walls of the crucible. The flow field of the melt is divided into two parts, inside and outside. The diameter of the inner volume is about 180mm, and it flows from the center to the outside as the crystal rotates. The outer roll rotates...

Embodiment 2

[0045] To grow single crystal silicon with a diameter of 154mm, a crucible with a diameter of 308mm was used, the rotation speed of the crystal was 10rpm, the rotation speed of the crucible was 5rpm, and the rotation direction of the crystal was opposite to that of the crucible. The double helix structure bottom heater made of hard carbon material, the size of the bottom heater is 154mm, the central resistivity is high, and the resistivity decreases from the center to the outside, and the resistance change is controlled by controlling the change of the width of the heater, which decreases every 10cm 5%. During crystal growth, the temperature at the center of the bottom of the crucible is controlled to be 8°C higher than that at the surrounding walls of the crucible. The flow field of the melt is divided into two parts, inside and outside. The diameter of the inner volume is about 205mm, and it flows from the center to the outside as the crystal rotates. The outer roll rotates...

Embodiment 3

[0047] On the basis of Example 2, the power of the bottom heater was increased, and the temperature at the center of the bottom of the crucible was controlled to be 10° C. higher than that of the surrounding walls of the crucible. The flow field of the melt is divided into two parts, inside and outside. The diameter of the inner volume is about 220mm, and it flows from the center to the outside as the crystal rotates. The outer roll rotates with the crucible, flowing from the surrounding to the inside. After the two streams meet, they flow from the surface to the inside. The temperature gradient change at the growth interface is 9%, the crystal pulling speed is first fast and then slow, and the average speed of the equal-diameter growth section is 2.8mm / min. After dicing the wafer from the single crystal, the overall change in oxygen content on the analyzed wafer was 4.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com