Full-automatic electrified net blocking trolley and net blocking method thereof

A fully automatic, net-sealing vehicle technology, applied in overhead lines/cable equipment, cranes, etc., can solve problems such as high safety requirements, poor stability of bamboo frames, and delayed construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

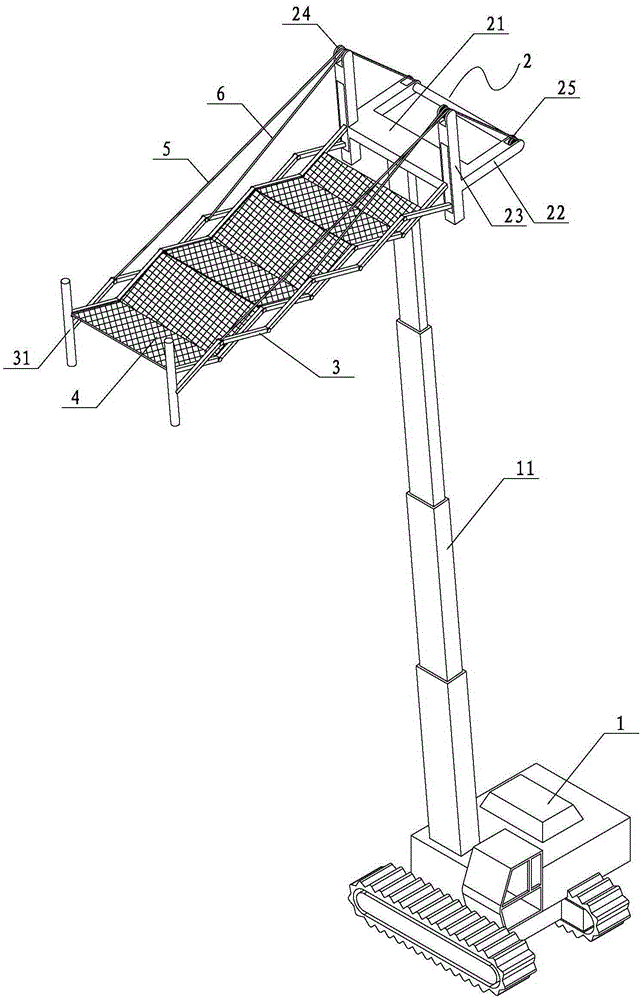

[0024] Such as figure 1 As shown in -2, a fully automatic live net-sealing vehicle includes a crane 1 and a net-sealing mechanism arranged on the top of the crane boom 11, wherein the net-sealing mechanism includes a bracket 2, a scissor fork telescopic arm 3, and a cable , Closure 4, hydraulic device, hoisting device and control device, the bracket 2 is fixedly installed on the top of the crane boom 11, the scissor fork telescopic arm 3 is arranged on the side of the bracket, and the scissor fork telescopic arm is controlled by the hydraulic device 3 stretches. The bracket 2 includes a horizontal main pole 21 arranged at the top of the crane boom 11, a supporting pole 22 horizontally arranged at both ends of the main pole 21, and a supporting pole 23 arranged longitudinally at both ends of the main pole 21. The top of the supporting pole 23 is A first guide wheel 24 is provided. One end of the support rod 22 is connected to the support rod 23 or the main rod 21, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com