Automatic laser cutting static electricity decarbonizing system and method for PI cover film

A technology of laser cutting and covering film, applied in the field of laser, can solve the problems of cutting and splicing accuracy affecting the quality of PI covering film, low production efficiency, affecting the quality of PI covering film, etc., to achieve the effect of automatic decarbonization of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

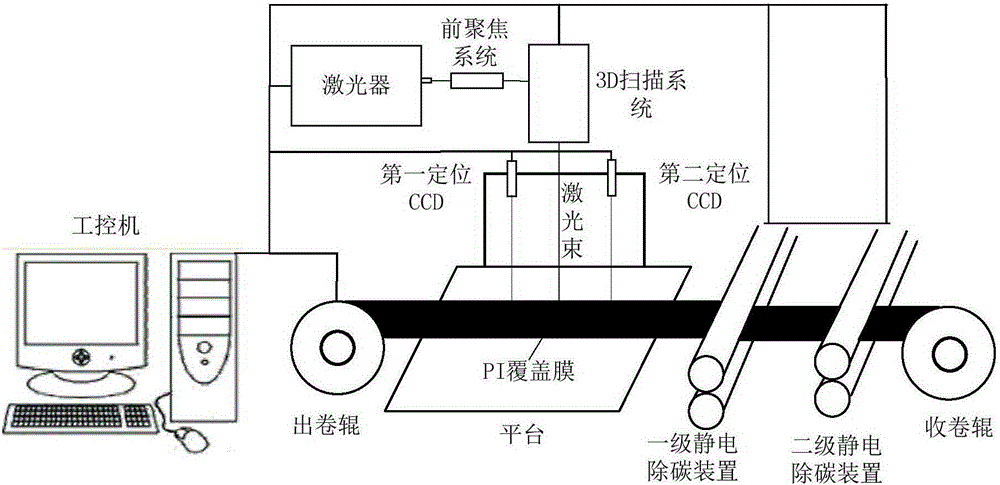

[0024] figure 1 It is a functional schematic diagram of a PI cover film automatic laser cutting electrostatic carbon removal system provided in this embodiment.

[0025] A PI cover film automatic laser cutting electrostatic decarbonization system, including: industrial computer, laser, 3D scanning system, positioning CCD, conveying device and electrostatic decarbonizing device, wherein the laser, 3D scanning system, positioning CCD, conveying device and the electrostatic carbon removal device are all connected to the industrial computer, and the conveying device is provided with a platform for placing the PI cover film to be processed. When the PI cover film is processed, the platform is processed from the 3D scanning system by the conveying device. Drive to the processing position of the electrostatic decarbonization device, wherein the conveying device includes an unwinding roller and a winding roller, and the positioning CCD is located above the processing position of the 3...

Embodiment 2

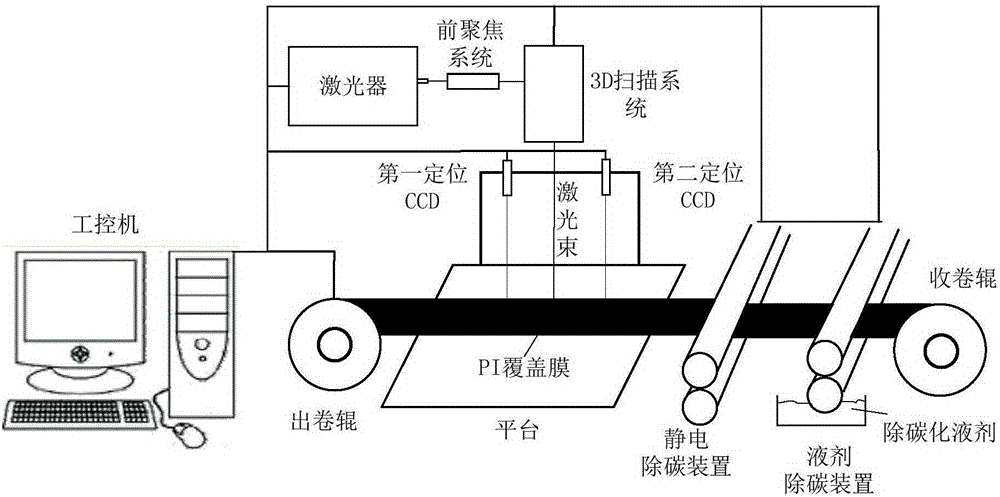

[0034] Such as figure 2 As shown, as another embodiment, it also includes a liquid agent carbon removal device, the liquid agent carbon removal device is located between the electrostatic carbon removal device and the winding roll, and the liquid agent carbon removal device includes an upper roller and a lower roller , the lower roller is controlled by an industrial computer to automatically add a decarbonization liquid agent. Different from the two-stage electrostatic decarbonization device, this embodiment adopts a two-stage decarbonization device that combines an electrostatic decarbonization device and a liquid agent decarbonization device. The carbon removal devices are combined and complement each other, and the carbon removal effect is better.

[0035] In this embodiment, the liquid agent carbon removal device is a roll-to-roll carbon removal device, which removes the carbonized dust on the cutting edge of the PI cover film through rolling friction and the action of th...

Embodiment 3

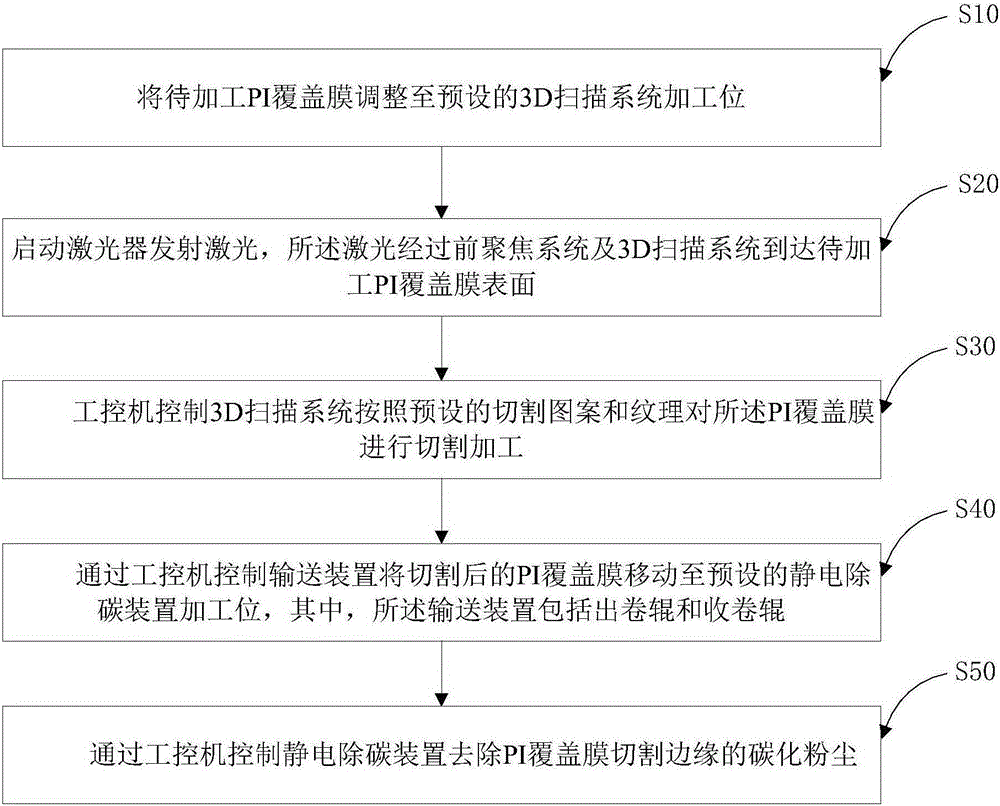

[0037] Such as image 3 Shown, a kind of PI covering film automatic laser cutting electrostatic decarburization method, comprises:

[0038] S10. Adjust the PI cover film to be processed to the preset processing position of the 3D scanning system;

[0039] S20, start the laser to emit laser, and the laser reaches the surface of the PI cover film to be processed through the front focusing system and the 3D scanning system;

[0040] S30, the industrial computer controls the 3D scanning system to cut and process the PI cover film according to the preset cutting pattern and texture;

[0041] S40. Using the industrial computer to control the conveying device to move the cut PI cover film to the preset processing position of the electrostatic decarbonization device, wherein the conveying device includes a winding roller and a winding roller;

[0042] S50. Control the electrostatic carbon removal device through the industrial computer to remove the carbonized dust on the cutting edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com