Extrusion machine for automobile exhaust pipe pressure device

A pressure device and exhaust pipe technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as mold wear and tear, improve mold life, improve work efficiency, The effect of increasing the strength of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

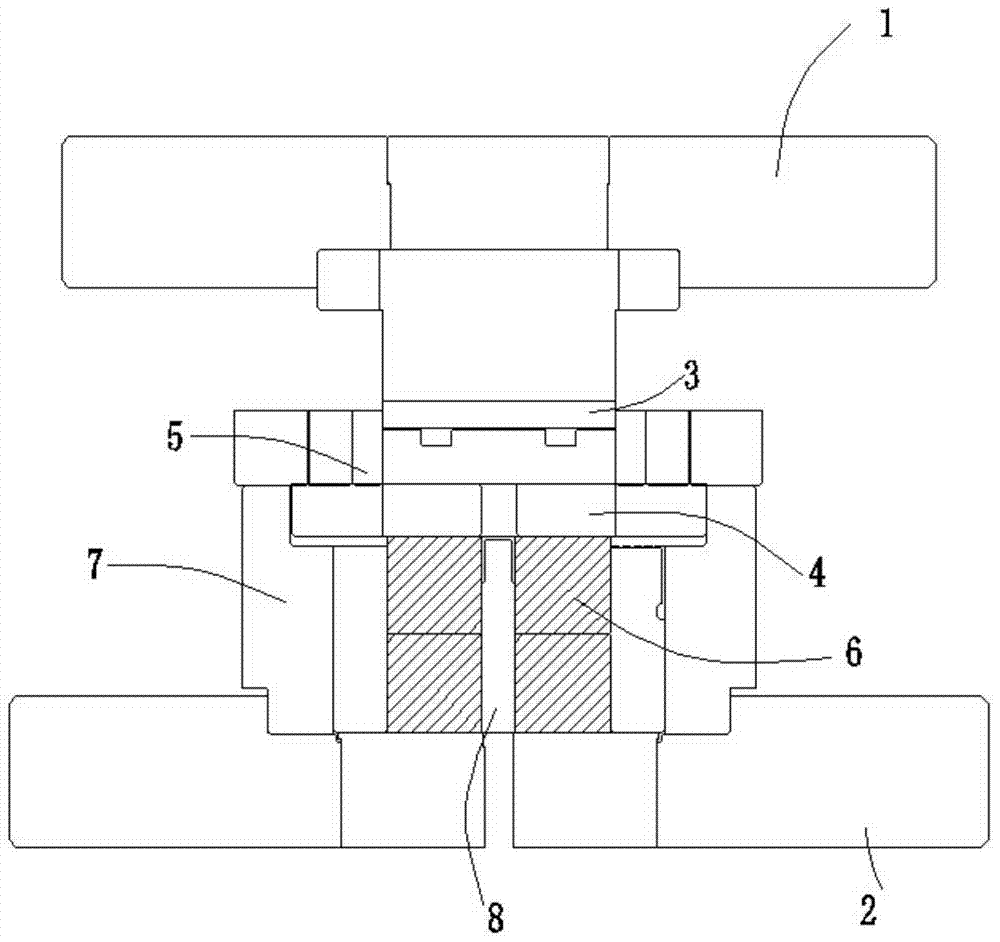

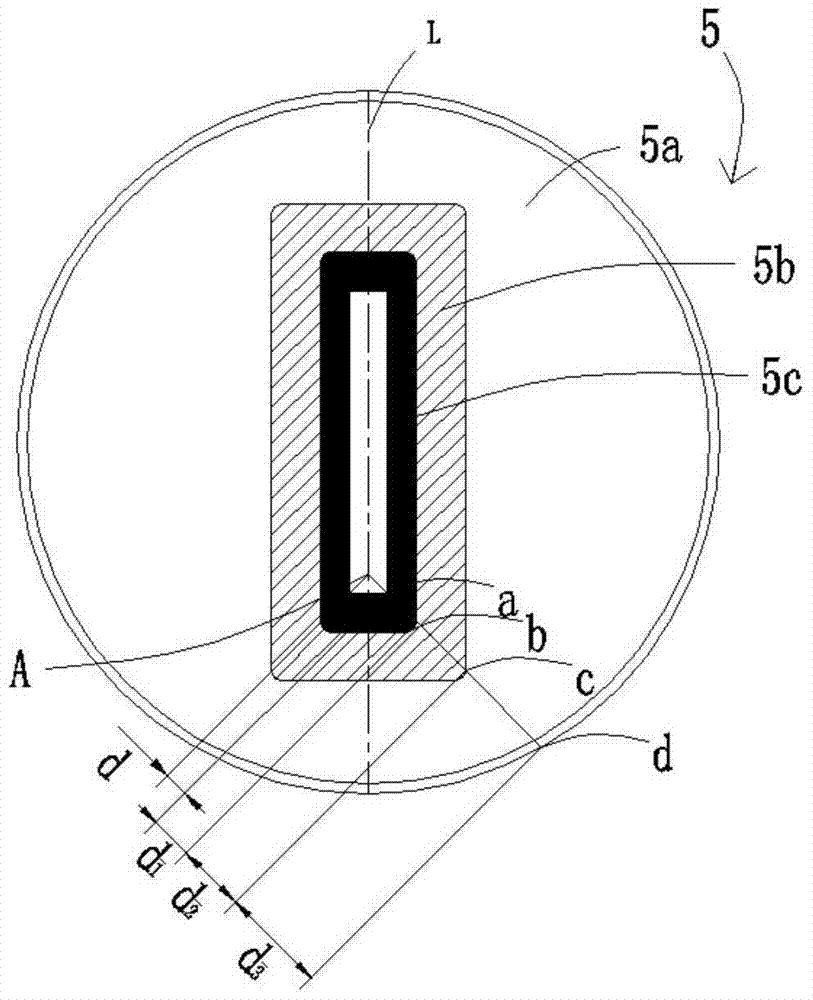

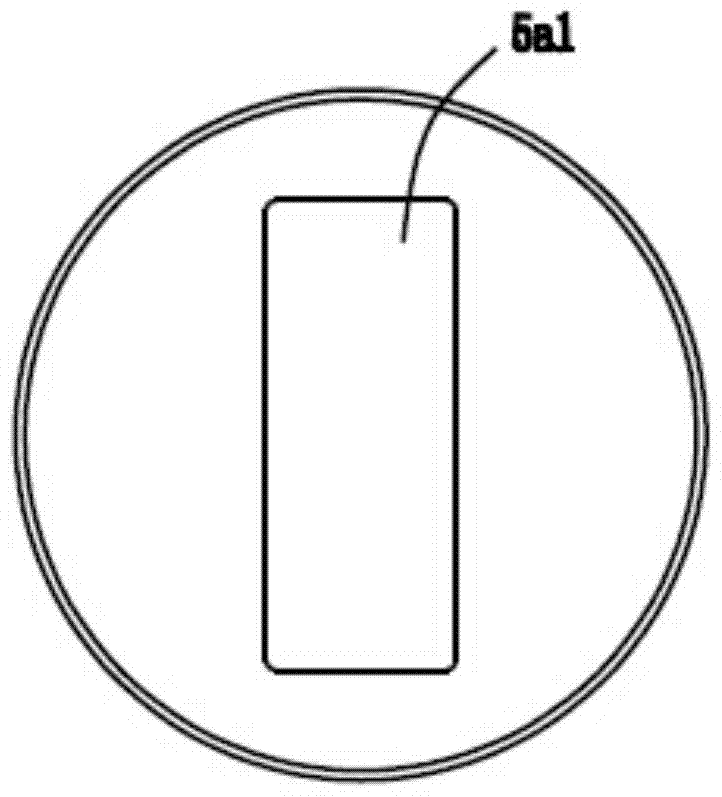

[0026] Picture 1-1 It is a schematic diagram of the first embodiment of the extruder of the automobile exhaust pipe pressure device, Figure 1-2 Schematic diagram of a partial enlarged top view of the middle and lower mold of the extrusion machine for the exhaust pipe pressure device for automobiles, figure 2 It is a schematic diagram of the outer insert 5a of the lower mold in Embodiment 1, image 3 It is a schematic diagram of the inner insert 5b of the lower mold in Embodiment 1, Figure 4 It is a schematic diagram of the central insert 5c of the lower mold in the first embodiment. Such as Picture 1-1 , Figure 1-2 , figure 2 , image 3 and Figure 4 As shown, this embodiment 1 provides a stamping machine for an automobile exhaust pipe pressure device, including an upper mold base 1, a lower mold base 2, an upper mold 3, an extrusion base plate 4, a lower mold 5, and a load-bearing platform 6 , fixed plate 7 and thimble bar 8. The upper mold base 1 is fixedly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com