A splicing die

A spliced, concave die technology, applied in the field of mechanical forging, can solve the problems of die wear and tear, and achieve the effect of improving the life of the die, improving the work efficiency, and improving the life of the die.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

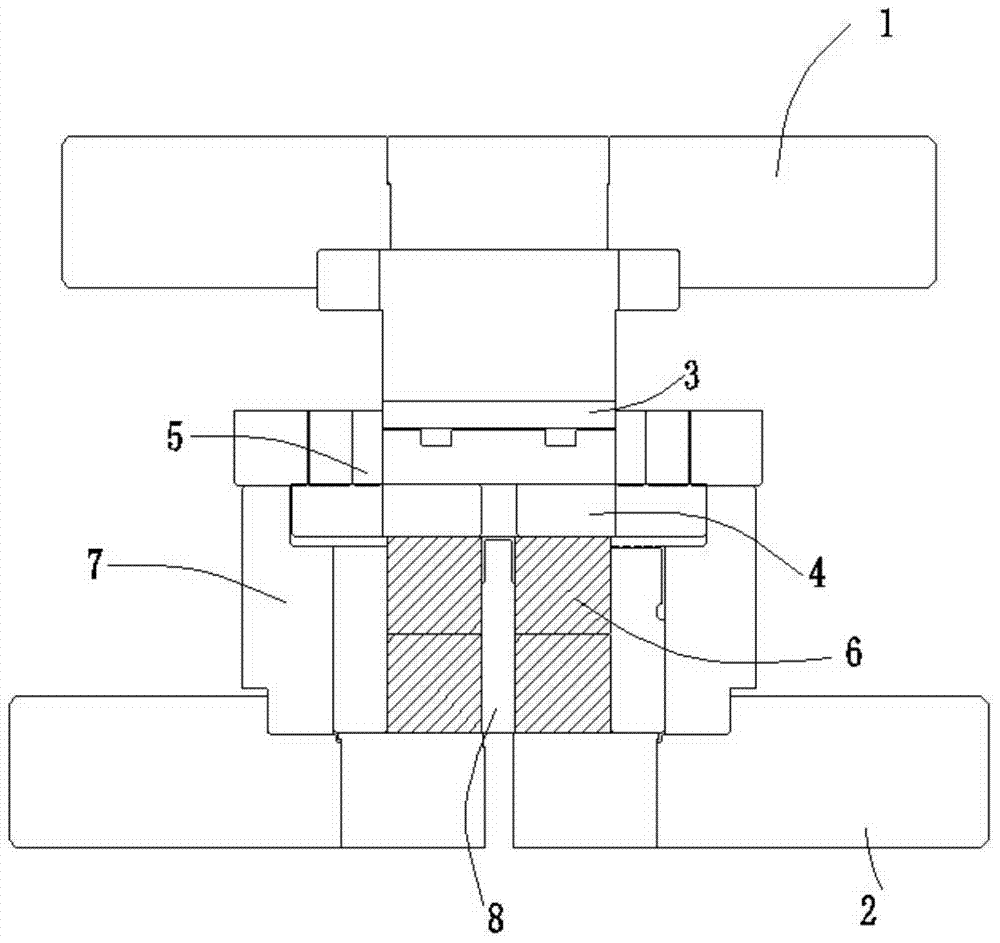

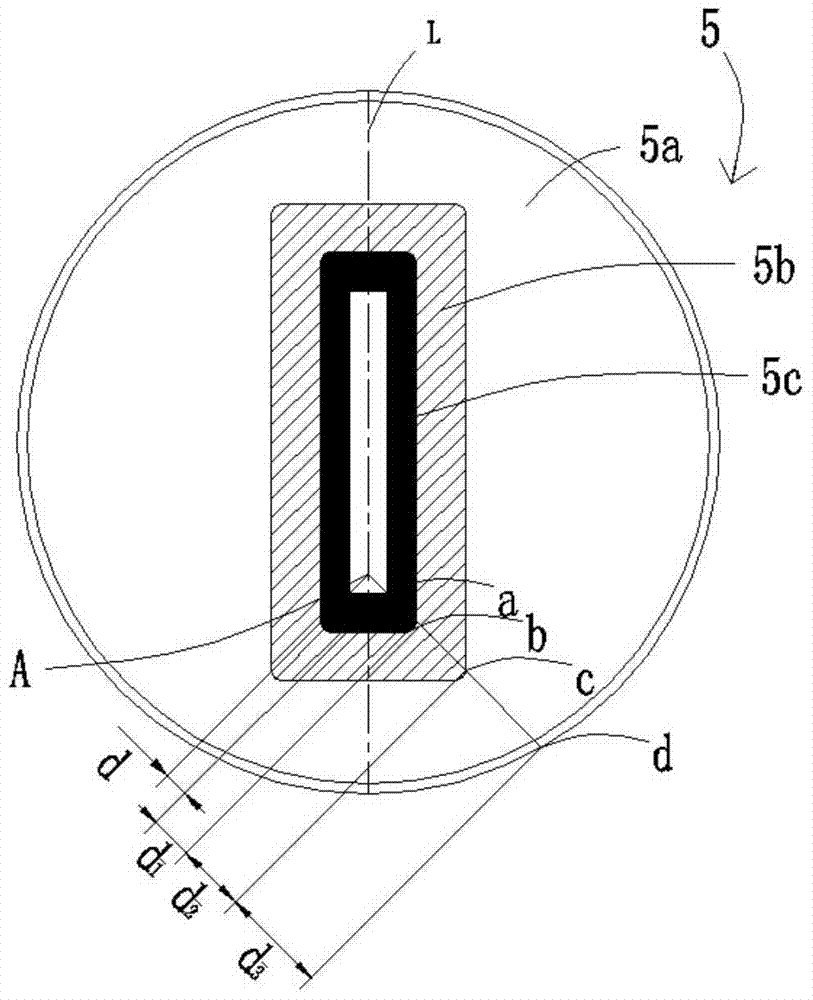

[0028] Picture 1-1 A schematic diagram of an extrusion machine for an automobile exhaust pipe pressure device applying a splicing die of the present invention, Figure 1-2 It is a schematic diagram of Embodiment 1 of a spliced die of the present invention, figure 2 It is a schematic diagram of the outer insert 5a of the lower mold in Embodiment 1, image 3 It is a schematic diagram of the inner insert 5b of the lower mold in Embodiment 1, Figure 4 It is a schematic diagram of the central insert 5c of the lower mold in the first embodiment. Such as Picture 1-1 , Figure 1-2 , figure 2 , image 3 and Figure 4 As shown, this embodiment 1 provides a stamping machine for an automobile exhaust pipe pressure device, including an upper mold base 1, a lower mold base 2, an upper mold 3, an extrusion base plate 4, a lower mold 5, and a load-bearing platform 6 , fixed plate 7 and thimble bar 8. The upper mold base 1 is fixedly connected with the upper mold 3, the extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com