Large-curvature three-dimensional hook face multi-step forming method based on gradually-changed mold molded face

A technology of mold profile and three-dimensional curved surface, which is applied in the multi-step forming of large-curvature three-dimensional curved surface and the field of press forming of large-curvature three-dimensional curved surface parts, which can solve the problems of difficult forming and prone to wrinkling defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

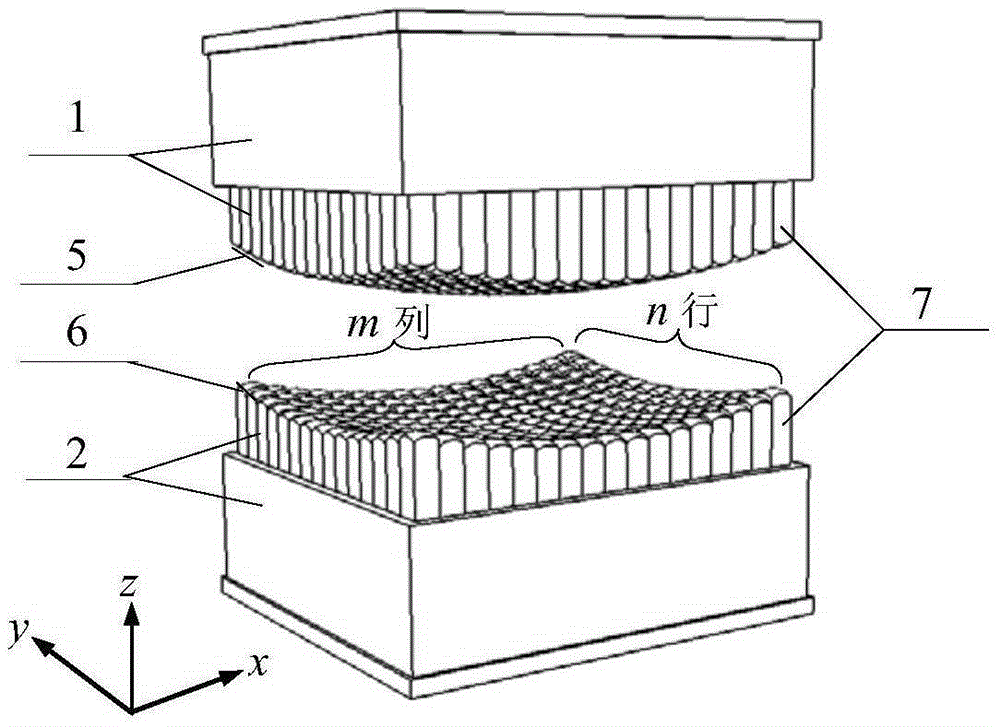

[0045] The multi-step forming method of the large-curvature three-dimensional curved surface based on the gradient mold surface involved in the present invention uses a set of discrete upper mold 1 and lower mold 2 with adjustable surface as forming tools, such as figure 1 As shown, the discrete upper mold 1 and the lower mold 2 are composed of regularly arranged m columns and n rows of basic body units 7, the height of each basic body unit is adjustable, and the top of the basic body unit is a spherical cap. The surface 5 of the upper mold 1 is composed of the envelope surface of the basic body unit of the upper mold, and the surface 6 of the lower mold 2 is composed of the envelope surface of the basic body unit of the lower mold. Adjusting the height of the basic body unit 7 can change the discrete mold The curved surface shape of the upper mold surface 5 and the lower mold surface 6.

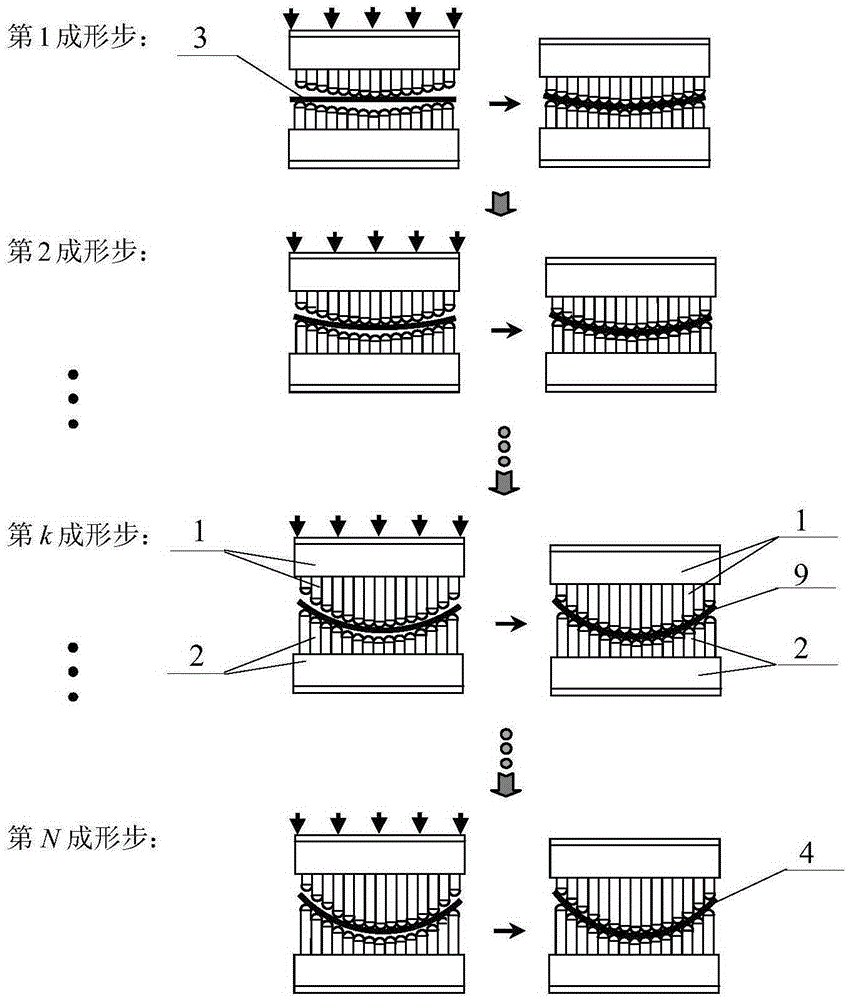

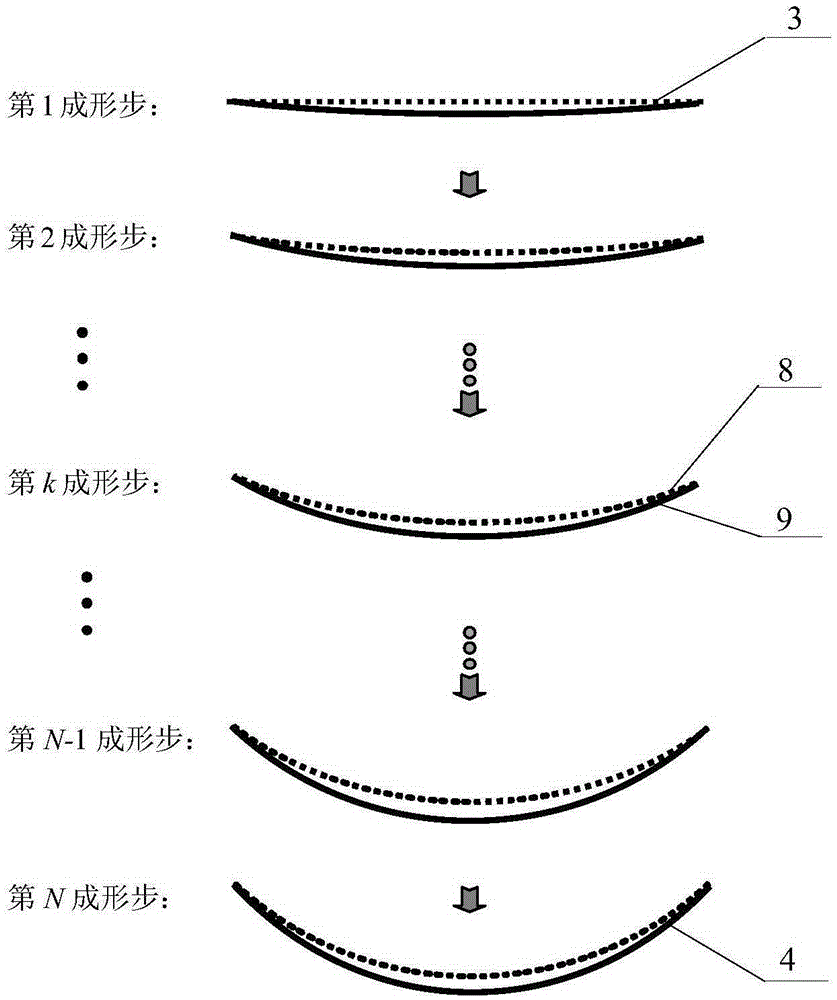

[0046] like figure 2 As shown, the upper mold surface 5 and the lower mold surface 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com