Combined collecting agent for flotation of cryptocrystalline graphite ore

A cryptocrystalline graphite and collector technology, used in flotation, solid separation, etc., can solve the problems of difficulty in selecting high-carbon graphite products, serious inclusion of gangue minerals, poor selectivity, etc., to improve development and utilization. Value, the effect of efficient development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

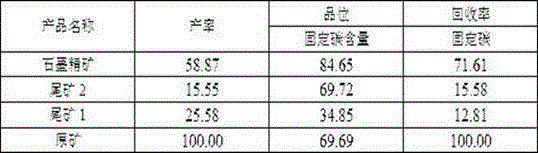

Embodiment 1

[0025] The raw ore is selected from a cryptocrystalline graphite mine in Hunan. The fixed carbon content in the ore is 70%. The shape of the ore is generally similar to coal under the naked eye. Graphite is the main mineral in the ore, the main gangue minerals are mica, quartz and chlorite, and a small amount of calcite and metal sulfides. The main purpose is to recover mineral graphite as aphanitic graphite produced by contacting metamorphic deposits of primary sedimentary rocks, also known as soil graphite.

[0026] Combined collector of the present invention is used for following ore dressing process, comprises the following steps:

[0027] (1) Grinding the raw ore to -0.074mm accounts for 85%;

[0028] (2) Add 800g / t combined collector to the ground raw ore, stir for 2 minutes and then carry out graphite flotation. The roughing time is 10 minutes to obtain graphite rough concentrate and tailings;

[0029] (3) Regrind the coarse graphite ore, and the regrinding fineness i...

Embodiment 2

[0037] The raw ore is selected from a cryptocrystalline graphite mine in Guizhou, and the fixed carbon content in the ore is 50%. Graphite is the main mineral in the ore, and the main gangue minerals are quartz, dolomite, mica and a small amount of calcite and metal sulfides.

[0038] Combined collector of the present invention is used for following ore dressing process, comprises the following steps:

[0039] (1) Grinding the raw ore to -0.074mm accounts for 75%;

[0040] (2) Add 500g / t of combined collector to the ground raw ore, stir for 2 minutes, and then carry out graphite roughing, the roughing time is 6 minutes, and obtain graphite rough concentrate and tailings;

[0041] (3) Regrind the graphite coarse concentrate, and the regrinding fineness is -0.023mm, accounting for 80%. After regrinding, add 200g / t of combined collectors, stir for 2 minutes and then select, and the flotation time is 8 Minutes to obtain graphite concentrate one, add 150g / t combined collector to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com