A beneficiation process utilizing grade differentiation of potassium feldspar

A kind of potassium feldspar and differentiated technology, which is applied in the field of separation, purification and utilization of feldspar mines, can solve the problems of low resource utilization rate and inability to fully develop the potential value of resources, and achieve high comprehensive utilization rate of resources and potential value of resources Give full play to the effect of increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1 Low-grade potassium feldspar beneficiation process

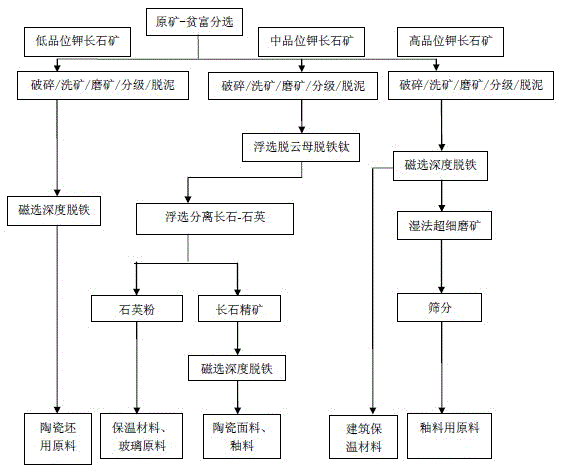

[0031] The process flow is: raw ore - separation of rich and poor - low grade ore - crushing - ore washing - grinding and classification - desliming - magnetic separation deep iron removal.

[0032] After the raw ore is sorted, it is coarsely crushed by the jaw crusher and finely crushed by the cone crusher, and the low-grade potassium feldspar ore (the composition of the raw ore is K 2 O: 5.76%, Na 2 O: 2.4%, Fe 2 o 3 : 0.8%, the raw ore whiteness is 28 degrees) as the raw material, the ore feed rate is 98 tons / day, the outlet concentration of the rod mill is 40-60%, the grinding fineness below 200 mesh accounts for 30-40%, the spiral classifier The outlet concentration is 40-50%, and the grading fineness below 200 mesh accounts for 30-40%. Desliming is carried out under the combination of cyclone and spiral chute, and after weak magnetic field (5000GS) and strong magnetic field (10000~13000GS), the com...

example 2

[0033] Example 2 Medium grade potassium feldspar mineral processing technology

[0034] The process flow is: raw ore - separation of rich and poor - medium grade ore - crushing - ore washing - grinding and classification - desliming - flotation demica deferrification titanium - secondary flotation dequartz - magnetic separation deep deironing.

[0035] After the raw ore is sorted, medium-grade potassium feldspar ore (raw ore composition is K 2 O: 8.1%, Na 2 O: 2.5%, Fe 2 o 3: 0.56%, the raw ore whiteness is 32 degrees), coarsely crushed by jaw crusher and finely crushed by cone crusher, the feed rate of rod mill is 100 tons / day, the outlet concentration is 40-60%, and the ore is ground below 200 mesh The fineness accounts for 30-40%. After passing through the spiral classifier, the outlet concentration of the classifier is 40-50%, and the classification fineness below 200 mesh accounts for 20-30%. Under the action of cyclone and spiral chute for desliming, the deslimed ore...

example 3

[0036] Example 3 High-grade potassium feldspar beneficiation process

[0037] The process flow is: raw ore - separation of rich and poor - high grade ore - crushing - ore washing - grinding and classification - desliming - magnetic separation deep iron removal - wet ultrafine grinding - screening.

[0038] After raw ore sorting, high-grade potassium feldspar ore (raw ore composition is K 2 O: 11.2%, Na 2 O: 2.3%, Fe 2 o 3 : 0.45%, the whiteness of raw ore is 25 degrees), after being coarsely crushed by the jaw crusher and finely crushed by the cone crusher, it enters the rod mill. , The grinding fineness below 200 mesh accounts for 30-40%, after passing through the spiral classifier, the outlet concentration of the classifier is 30-40%, and the classification fineness below 200 mesh accounts for 30-40%. After desliming by cyclone and spiral chute, and then desliming by weak magnetic field and strong magnetic field, the composition of potassium feldspar concentrate obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com