Mass transfer heat exchange grill packing for washing dust collector

A technology for grid packing, washing and dust removal, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc. The effect is not ideal, the specific surface area of the grid plate is small, etc., to achieve the effect of increasing the capture opportunity, improving the dust removal effect, and rationalizing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

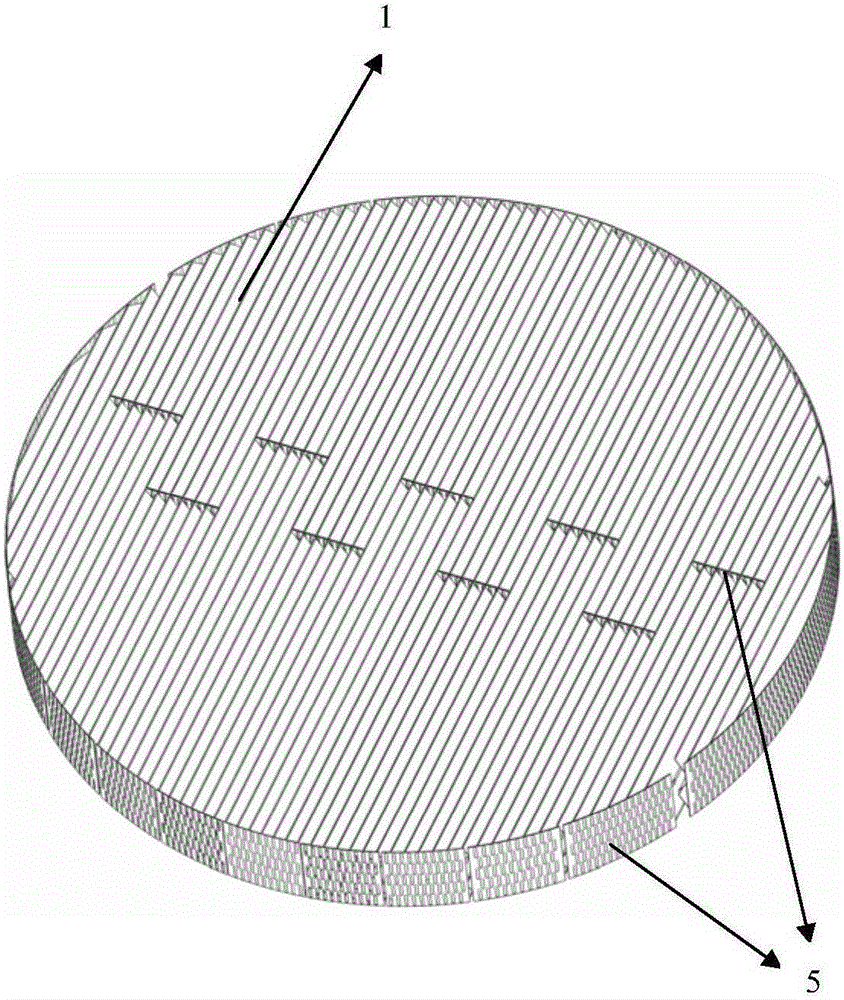

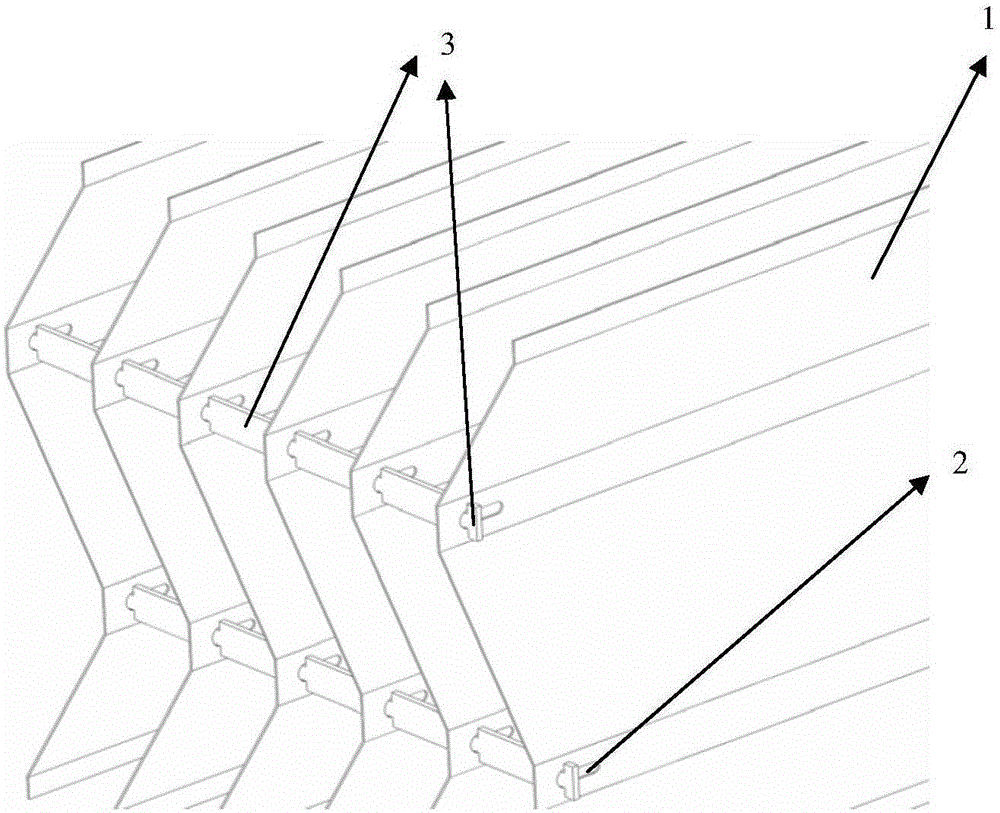

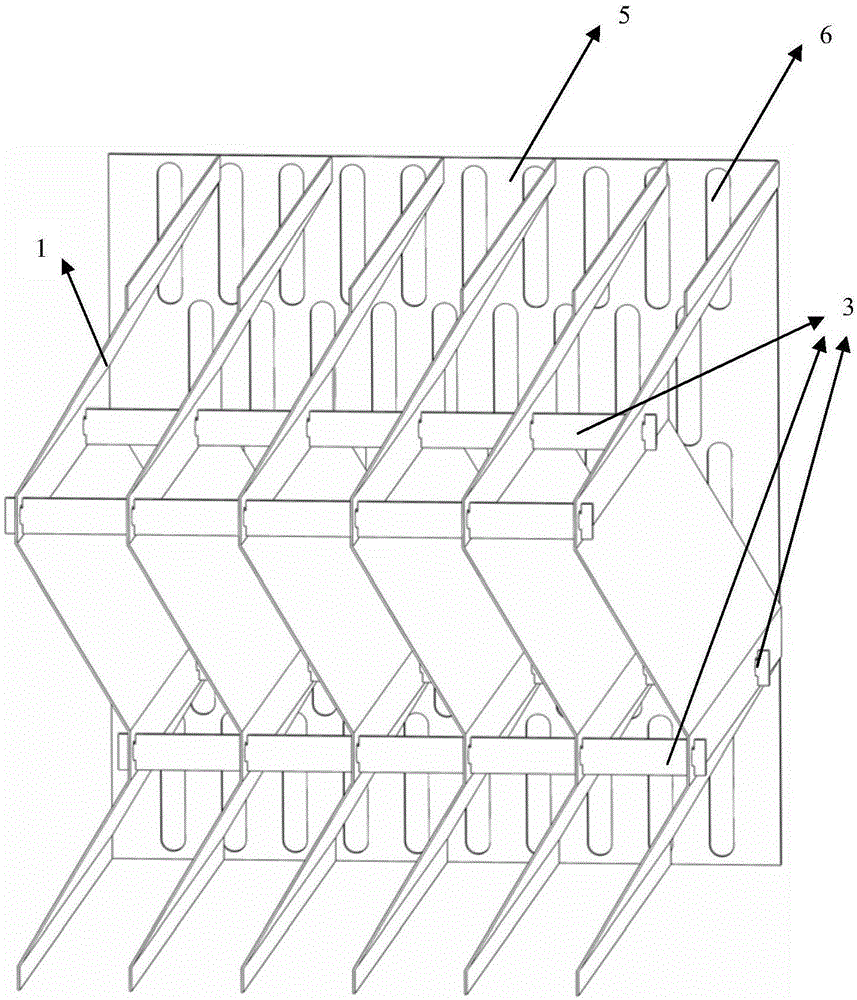

[0030] A heat exchange grid filler for washing and dust removal devices, comprising a plurality of corrugated plates arranged in parallel, each folded peak of the corrugated plate is provided with a plurality of perforations with the same size and the same direction, and each folded peak of the corrugated plate The perforations on the grid are all on the same level. After the connecting plate passes through the perforation, several corrugated plates are fixed in series to form a corrugated packing block, that is, a grid packing block unit of the grid packing. The size of the grid packing block unit is determined by the tower. The diameter of the manhole is determined;

[0031] The shape of the perforation is circular arcs with different diameters at both ends and a rectangle in the middle. The length of the perforation is the maximum distance be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com