Bare-handed nail implantation external fixation system

An external fixation and nail placement technology, applied in the field of external fixation systems, can solve the problems of high difficulty, low reliability, and inability to correct and reduce the fracture site, and achieve the effects of reducing disability rate, reliable performance and improving survival.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] When the free-hand nail external fixation system is not in use, parts can be disassembled and put into a small storage box or a medical bag, and when assembled, all parts can be taken out for assembly and nailing.

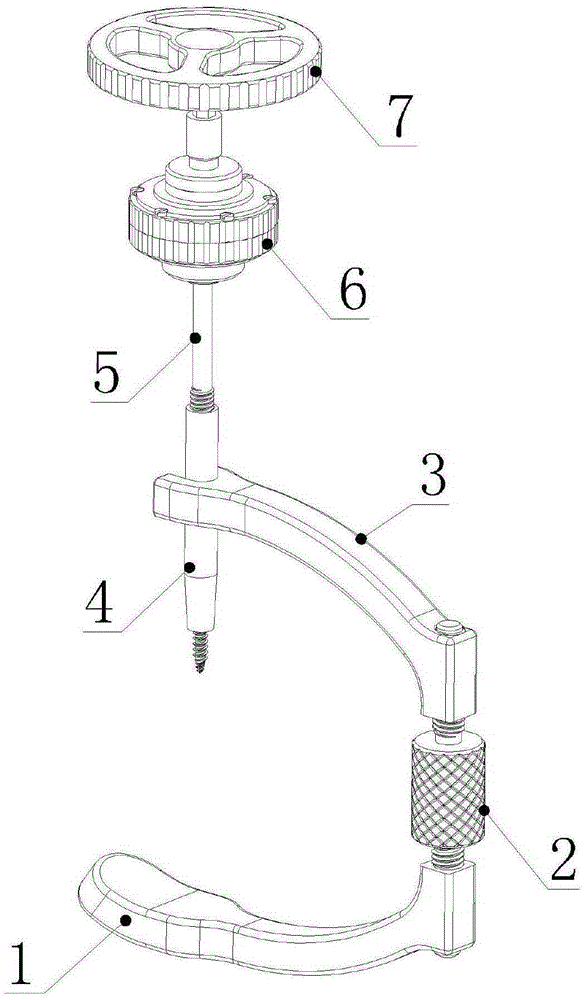

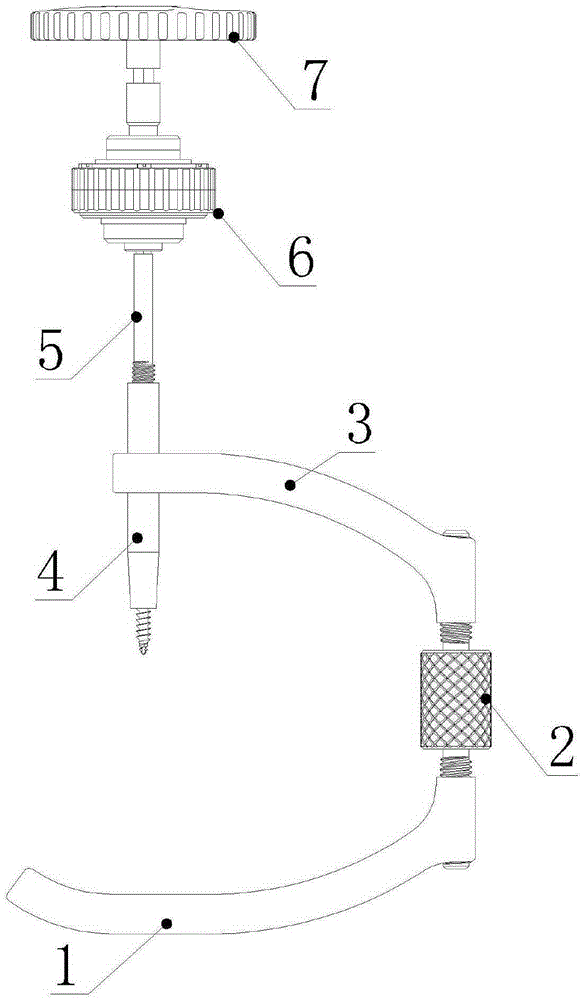

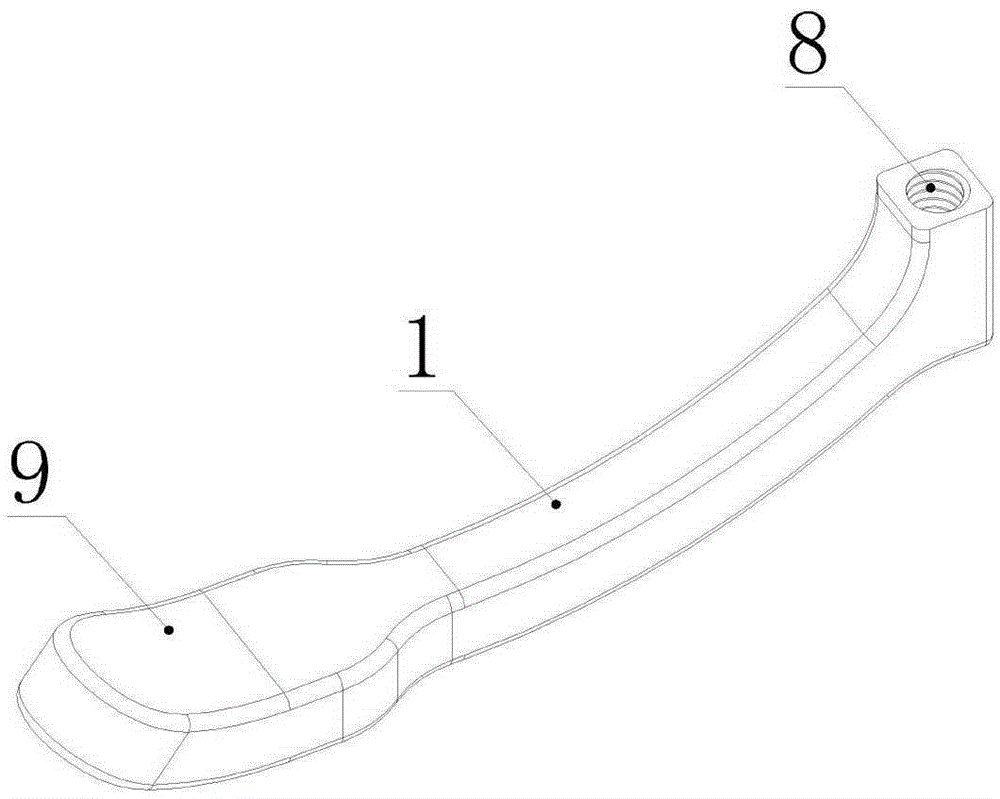

[0021] An external fixation system for free-hand nail placement, characterized in that the system is composed of an external fixation bracket, a gear pair mechanism 6, a bone nail 5 and a matching rotating handle 7, and the external fixation bracket is integrally formed into a three-sided closed tiger's mouth shape, and is composed of The lower curved rod 1, the vertical rod 2, the upper curved rod 3 and the threaded sleeve 4 are composed; the lower curved rod 1 and the vertical rod 2 are respectively provided with internal threads, and the tail end of the lower curved rod 1 is thickened Support base 9, the head section of the lower arc-shaped rod 1 is provided with a pipe hole 8 with internal thread; the head and tail ends of the vertical rod 2 are externall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com