Device and method for gradient concentration using waste heat mechanical pressurization coupled with enzyme membrane method

A technology of mechanical pressurization and coupling of enzyme membranes, applied in chemical instruments and methods, membranes, applications, etc., can solve the problems of large concentration of material and liquid, huge temperature difference, affecting the flavor of soup liquid, etc., and achieve the effect of improving characteristic attributes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

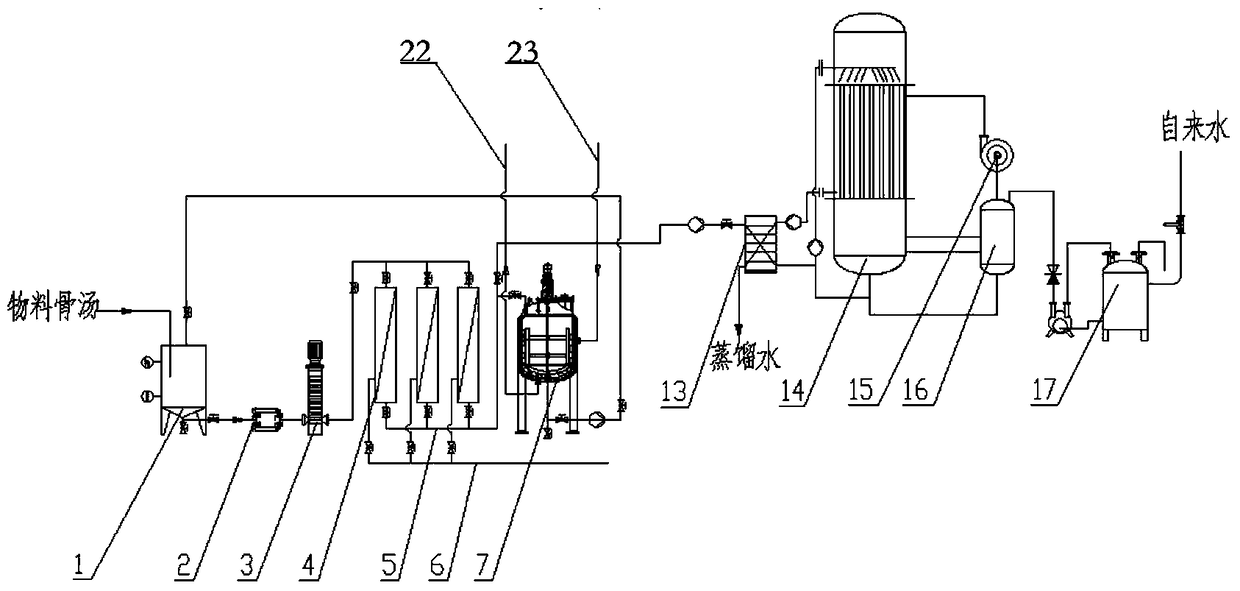

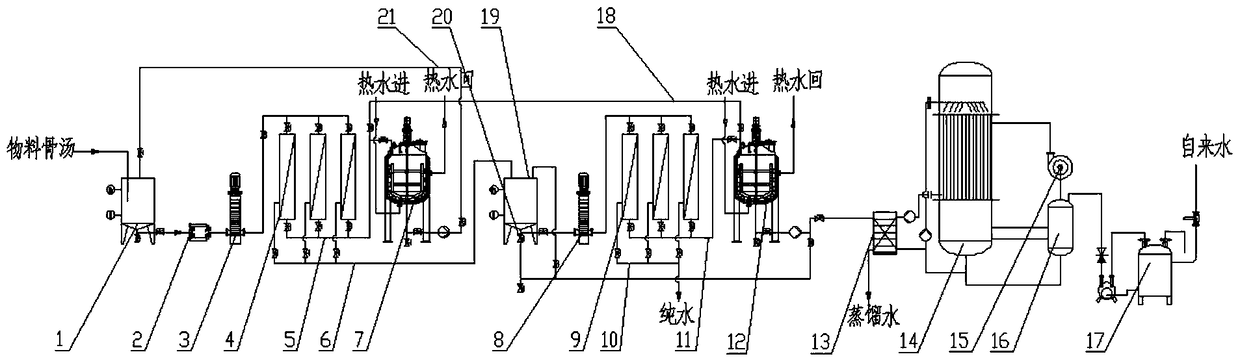

[0041] Such as figure 1 As shown, a device for gradient concentration using waste heat mechanical pressurization coupled with enzyme membrane method is characterized in that it comprises:

[0042] The ultrafiltration membrane filtration unit includes a raw material soup balance barrel 1, an ultrafiltration membrane original 4 and a first enzymolysis tank 7, wherein the liquid outlet of the raw material soup balance barrel and the liquid inlet of the ultrafiltration membrane original The outlet of the ultrafiltration concentrate of the original ultrafiltration membrane is connected with the inlet of the enzymolysis tank through an ultrafiltration concentrate pipe, and the outlet of the enzymolysis tank is in equilibrium with the raw soup The liquid inlet of the barrel is connected through the circulation pipe 21;

[0043] A mechanical booster concentration unit, which is a vacuum concentration device. The liquid inlet of the mechanical booster concentration unit and the ultrafiltrat...

Embodiment 2

[0052] Such as Figure 5 As shown, a method for applying a gradient concentration device for gradient concentration is characterized in that it includes the following steps:

[0053] Step 1: Perform cyclic enzymolysis for 0.5-3 hours on the raw material soup in the raw material soup balance tank, the original ultrafiltration membrane and the first enzymolysis tank to prepare an enzymatic ultrafiltration concentrate;

[0054] Step 2: Perform gradient concentration of the enzymatic hydrolysis ultrafiltration concentrate to obtain concentrates of different concentrations.

[0055] In one embodiment, the specific method for preparing the raw material soup into the enzymatic hydrolysis ultrafiltration concentrate includes the following steps:

[0056] 1.1. Pour the raw material soup into the raw material soup balance tank, and obtain the ultrafiltration concentrated liquid after filtering through the original ultrafiltration membrane, which is ready for use;

[0057] 1.2. The ultrafiltratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com